Explore the Basics of Magnetic Filters: An Introduction and Guide

Magnetic filters are devices designed to remove ferrous particles and other magnetic contaminants from fluids such as water, oil, coolants, and lubricants. They exist to protect equipment and systems from damage caused by unwanted metallic particles. These filters are widely used in industries like manufacturing, food processing, pharmaceuticals, energy, and water treatment.

The principle is straightforward: a magnetic field attracts and traps magnetic particles while allowing clean fluid to pass through. By capturing these contaminants, magnetic filters prevent wear, blockages, and breakdowns in sensitive systems. Over time, they have become an essential component of preventive maintenance across multiple sectors.

Importance

Magnetic filters matter because they address common issues in fluid systems and machinery. Even tiny amounts of ferrous particles can cause significant problems, including wear on moving parts, decreased efficiency, or product contamination.

Key reasons why magnetic filters are important today include:

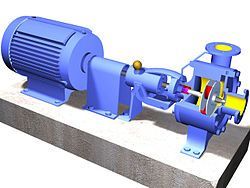

Protecting machinery: They reduce downtime and extend the lifespan of pumps, compressors, turbines, and other rotating equipment.

Improving efficiency: Clean fluids flow more smoothly, lowering energy consumption and enhancing process performance.

Ensuring product quality: In industries like food or pharmaceuticals, magnetic filters help maintain purity and safety standards.

Reducing environmental risks: By trapping particles before they enter drainage or disposal systems, filters minimize pollution.

Those most affected by this technology include engineers, facility managers, quality assurance teams, and industries that rely on fluid circulation systems. Without filters, equipment maintenance would be more frequent, costly, and less sustainable.

Recent Updates

Magnetic filtration technologies have seen several advancements in 2024 and 2025. Among the most notable:

High-intensity rare earth magnets (2024): These magnets significantly improve particle capture, even for fine contaminants.

Compact filter designs (2024): Smaller yet powerful systems are being integrated into modern machinery without requiring large footprints.

Hybrid filtration systems (2025): Some filters now combine magnetic separation with mesh or cartridge filters for comprehensive cleaning.

Smart monitoring features (2025): Digital sensors are being integrated to track particle buildup and send alerts when maintenance is required.

Sustainability focus (2025): Magnetic filters are gaining attention as eco-friendly alternatives since they reduce disposable filter waste.

Industry reports in 2025 highlight the rising demand for advanced filtration solutions in renewable energy projects and precision manufacturing, where clean fluids are essential.

Laws or Policies

Magnetic filters, like other filtration technologies, are influenced by industry standards and government regulations. These rules vary by sector and region, but some examples include:

Food and beverage regulations: In the European Union and the United States, food safety laws require contamination control, and magnetic filters are widely used to comply with these hygiene standards.

Pharmaceutical industry guidelines: Good Manufacturing Practices (GMP) often include requirements for contamination prevention, where magnetic filters play a role in equipment compliance.

Environmental policies: Wastewater discharge regulations encourage or mandate the removal of contaminants before disposal, supporting the adoption of magnetic filters in water treatment plants.

ISO standards: International standards for filtration systems ensure consistent design, testing, and quality across industries.

In some countries, environmental agencies are promoting stricter rules for industrial discharge, which indirectly increases the use of magnetic separation systems.

Tools and Resources

Various tools and resources are available for learning about and implementing magnetic filters:

Magnetic field calculators: Online tools that estimate the strength of magnetic fields used in filters.

Simulation software: Programs like COMSOL Multiphysics can model particle behavior in magnetic fields.

Engineering handbooks: Technical papers and reference guides explain fluid dynamics and separation methods.

Training courses: Universities and professional organizations provide educational resources on magnetic filtration technologies.

Monitoring apps and dashboards: Digital tools integrated with sensors help track filter performance in real time.

These resources are helpful for both professionals in technical industries and students studying engineering or environmental science.

FAQs

What does a magnetic filter do?

A magnetic filter removes ferrous particles and other magnetic contaminants from fluids such as oil, water, or coolants. It prevents these particles from causing damage to machinery or contaminating products.

Where are magnetic filters most commonly used?

They are widely applied in industries such as manufacturing, food and beverage processing, power generation, automotive, and water treatment.

Are magnetic filters reusable?

Yes, most magnetic filters are reusable. The captured particles can be cleaned off the magnet surfaces, making them a sustainable option compared to disposable filters.

How do magnetic filters improve efficiency?

By keeping fluids free of metal particles, these filters reduce friction, wear, and blockages, which helps machinery run more smoothly and reduces energy consumption.

Do magnetic filters capture non-metallic particles?

Primarily, they capture ferrous and magnetic materials. However, when used in combination with other filtration methods, they contribute to removing non-magnetic particles as well.

Conclusion

Magnetic filters are a simple yet powerful solution to one of the most persistent challenges in industrial systems: contamination by ferrous particles. Their role spans across industries, protecting equipment, improving efficiency, and ensuring safety and quality.

Recent innovations such as hybrid systems, smart monitoring, and sustainability-driven designs are shaping the future of filtration. As industries face stricter regulations and environmental demands, magnetic filters will remain a reliable and evolving technology.