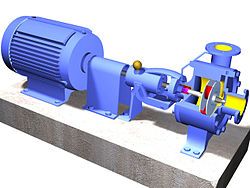

Centrifugal Pumps Introduction: Explanation, Types, and Useful Insights

Centrifugal pumps are one of the most widely used machines in industrial and domestic applications. They operate on the principle of centrifugal force, converting mechanical energy from a motor into kinetic energy in the fluid. This movement directs liquid outward through a rotating impeller, creating continuous flow.

The concept of centrifugal pumps dates back to the 17th century, but their widespread industrial adoption began during the 19th and 20th centuries with the growth of factories, water distribution networks, and oil refineries. Today, they are essential in water treatment, agriculture, chemical processing, HVAC systems, energy production, and countless other fields.

Centrifugal pumps exist because industries and households need a reliable, efficient, and scalable method of moving fluids. Unlike positive displacement pumps, which push fixed volumes of liquid, centrifugal pumps provide smooth, continuous flow with relatively low maintenance needs.

Importance

Centrifugal pumps play a vital role in modern life and industry. Their importance lies in several key areas:

-

Water supply and treatment: Cities and municipalities rely on centrifugal pumps for distributing drinking water and handling wastewater.

-

Energy and oil industries: These pumps circulate cooling water in power plants and manage petroleum in refineries.

-

Agriculture and irrigation: Farmers use them to move water from wells, rivers, or reservoirs to fields.

-

HVAC systems: Large buildings depend on centrifugal pumps to circulate chilled and hot water for heating and cooling.

-

Chemical processing: Industries use pumps to handle acids, solvents, and other fluids in controlled systems.

Who it affects:

-

Engineers and plant operators managing fluid systems.

-

Municipal authorities responsible for public water and sewage.

-

Manufacturers needing reliable fluid handling in production.

-

Farmers and rural communities relying on irrigation.

-

Households using pumps for residential water supply.

Problems it solves:

-

Eliminates the need for manual water movement.

-

Ensures reliable flow in industrial processes.

-

Supports large-scale infrastructure like power plants and urban water networks.

-

Reduces downtime and improves efficiency with modern designs.

Recent Updates

Centrifugal pump technology continues to evolve with trends in efficiency, sustainability, and automation. Notable updates from the past year include:

-

Energy-efficient designs (2024–2025): Manufacturers are focusing on pumps that reduce energy consumption, aligning with global energy-saving initiatives.

-

Smart monitoring systems (2024): IoT-enabled pumps now provide real-time data on vibration, pressure, and flow to predict failures before they occur.

-

Advanced materials (2024): The use of composite and corrosion-resistant materials increases durability, especially in chemical and marine environments.

-

Hydrogen industry applications (2025): As hydrogen energy expands, centrifugal pumps are being designed for safe handling of cryogenic and pressurized fluids.

-

Sustainability goals (2025): Industries emphasize pumps that support renewable energy projects and minimize carbon footprint.

Laws or Policies

Centrifugal pumps are influenced by regulations that vary across industries and countries. Important policy areas include:

-

Energy efficiency standards: In the EU, directives such as the EcoDesign regulation set minimum efficiency requirements for industrial pumps. The U.S. Department of Energy (DOE) has similar guidelines.

-

Environmental compliance: Pumps used in chemical, oil, and wastewater applications must meet environmental protection regulations like EPA standards in the United States.

-

Occupational safety regulations: OSHA in the U.S. and equivalent global organizations require pumps to be installed with safeguards to protect workers.

-

Water management policies: Governments often regulate pumps used in irrigation and municipal water systems to prevent over-extraction or contamination.

-

International standards: Organizations like ISO and ANSI publish guidelines for pump testing, installation, and performance to ensure global reliability.

Tools and Resources

Several tools, apps, and resources help engineers, businesses, and learners understand and optimize centrifugal pump usage.

-

Pump selection software: Tools like Grundfos Product Center and KSB EasySelect assist engineers in choosing the right pump based on flow and head requirements.

-

Energy calculators: Online calculators estimate power consumption and help identify opportunities for efficiency improvements.

-

Maintenance apps: IoT platforms such as ABB Ability monitor pump performance and provide predictive maintenance alerts.

-

Engineering databases: Websites like Pump Handbook Online provide technical charts, curves, and performance data.

-

Training resources: Organizations such as Hydraulic Institute offer educational material and certification programs.

Comparison Table: Types of Centrifugal Pumps

| Pump Type | Key Feature | Common Application |

|---|---|---|

| Single-stage pump | One impeller, simple design | Water supply, HVAC |

| Multi-stage pump | Multiple impellers in series | High-pressure applications |

| End-suction pump | Fluid enters at one side | Industrial and commercial |

| Vertical pump | Compact, vertical shaft | Wells, irrigation systems |

| Submersible pump | Operates underwater | Sewage, drainage, dewatering |

| Magnetic drive pump | Seal-less, corrosion-resistant | Chemicals, hazardous fluids |

FAQs

What is a centrifugal pump and how does it work?

A centrifugal pump is a machine that uses a rotating impeller to impart velocity to a liquid, converting mechanical energy into fluid flow. The liquid enters through the pump suction, gains energy from the impeller, and exits at a higher pressure.

What are the main advantages of centrifugal pumps?

They are simple in design, provide continuous flow, handle large volumes, and require relatively low maintenance compared to positive displacement pumps.

What industries use centrifugal pumps the most?

They are widely used in water supply, oil and gas, power generation, chemical processing, HVAC, and agriculture.

How are centrifugal pumps regulated?

Regulations cover energy efficiency, safety standards, and environmental compliance. For example, DOE rules in the U.S. and EcoDesign in Europe set efficiency benchmarks.

What is the difference between a centrifugal pump and a positive displacement pump?

A centrifugal pump provides variable flow depending on system conditions, while a positive displacement pump delivers a fixed volume regardless of pressure.

Conclusion

Centrifugal pumps remain one of the most essential technologies in engineering, industry, and everyday life. From municipal water supply to advanced energy systems, they ensure reliable fluid movement across a wide range of applications. Recent advancements in efficiency, smart monitoring, and material science highlight how these machines continue to adapt to modern demands.

Understanding the basics, types, and policies surrounding centrifugal pumps allows engineers, businesses, and learners to make informed decisions when designing and managing fluid systems. With ongoing innovation and regulatory alignment, centrifugal pumps will remain central to industries worldwide, supporting both economic growth and sustainability goals.