Explore Cable Manufacturers Machine Technology: Key Facts, Knowledge, and Insights

Cable manufacturers machine technology refers to the specialized equipment and systems used to produce electrical, data, fiber optic, and industrial cables. These machines exist to ensure cables are manufactured with precision, consistency, and safety, meeting the technical requirements of modern infrastructure.

Cables are essential for transmitting electricity, data, and signals across homes, industries, transportation systems, and digital networks. To meet growing global demand, manufacturers rely on advanced machinery to handle processes such as wire drawing, stranding, insulation, sheathing, armoring, and testing.

Without dedicated machine technology, producing cables at scale with consistent quality would be difficult. These machines help standardize production while supporting innovation in cable design and materials.

Importance

Cable manufacturers machine technology plays a critical role in today’s connected world. It affects industries such as energy, telecommunications, construction, transportation, and renewable power generation.

Key reasons this technology matters include:

-

Reliability: Ensures cables perform safely under electrical, mechanical, and environmental stress.

-

Efficiency: Automates complex processes, reducing human error and improving output consistency.

-

Scalability: Supports mass production needed for urbanization, smart cities, and digital expansion.

-

Innovation support: Enables development of advanced cables such as high-voltage, fire-resistant, and fiber optic cables.

This technology helps solve challenges such as signal loss, overheating, mechanical failure, and inconsistent insulation thickness. Engineers, technicians, infrastructure planners, and regulatory bodies all rely on accurate machine-driven production to ensure long-term system performance.

Recent Updates

Over the past year (2024–2025), cable manufacturing machinery has evolved in response to digital transformation and sustainability goals.

Key developments include:

-

Smart manufacturing systems (2024): Machines now integrate sensors and analytics to monitor speed, tension, temperature, and material usage in real time.

-

AI-assisted quality control (2024): Artificial intelligence is increasingly used to detect defects during insulation and sheathing processes.

-

Energy-efficient machinery (2025): New machine designs reduce power consumption, supporting environmental compliance goals.

-

Advanced extrusion technology (2025): Improved extrusion lines allow more precise insulation layering for high-performance cables.

-

Fiber optic machine upgrades (2024): Enhanced drawing towers and coating systems improve signal integrity and durability.

Industry reports published in late 2024 highlight increased investment in automation as global cable demand rises due to electric vehicles, renewable energy grids, and data center expansion.

Laws or Policies

Cable manufacturing machine technology is shaped by safety, quality, and environmental regulations. These rules vary by region but share common objectives.

Key regulatory influences include:

-

International Electrotechnical Commission (IEC) standards: Define technical requirements for cable performance and testing.

-

ISO manufacturing standards: Ensure consistent quality management and process control in machine-based production.

-

Electrical safety regulations: National authorities require compliance to prevent electrical hazards and system failures.

-

Environmental policies: Governments encourage reduced emissions, recyclable materials, and efficient energy use in manufacturing.

-

Worker safety laws: Machinery must comply with occupational safety rules to reduce operational risks.

In regions such as the European Union, regulatory frameworks also support digital manufacturing and sustainable industrial equipment through innovation programs and compliance incentives.

Tools and Resources

Several tools and resources help professionals understand and work with cable manufacturing machine technology.

Helpful examples include:

-

Cable design software: Digital tools used to model conductor size, insulation thickness, and material behavior.

-

Process simulation platforms: Software that simulates extrusion, stranding, and cooling processes.

-

Quality monitoring dashboards: Systems that analyze real-time machine data for defect prevention.

-

Technical standards libraries: Online access to IEC, ISO, and national electrical standards.

-

Engineering training platforms: Educational resources covering cable manufacturing processes and machine operation principles.

These tools support better planning, learning, and compliance across the cable manufacturing ecosystem.

FAQs

What types of machines are used in cable manufacturing?

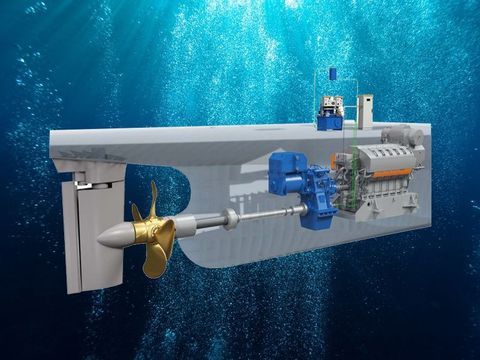

Common machines include wire drawing machines, stranding machines, extrusion lines, armoring machines, and testing equipment. Each supports a specific stage of cable production.

How does automation improve cable manufacturing?

Automation improves precision, reduces variation, enhances safety, and allows continuous monitoring of production parameters such as speed and temperature.

Why is extrusion technology important in cable machines?

Extrusion technology applies insulation and protective layers uniformly, which is essential for electrical safety, durability, and performance.

What role does digital monitoring play in modern machines?

Digital monitoring helps detect defects early, supports predictive maintenance, and improves overall production reliability.

Are cable manufacturing machines affected by sustainability rules?

Yes. Environmental policies encourage energy-efficient machines, reduced waste, and the use of recyclable or low-impact materials.

Conclusion

Cable manufacturers machine technology is a foundational element of modern infrastructure. It enables the production of reliable cables that support power distribution, communication networks, transportation systems, and emerging technologies.

Recent advancements in automation, smart monitoring, and energy efficiency demonstrate how machine technology continues to evolve alongside global demand. Regulations and standards ensure that these machines operate safely, responsibly, and consistently across regions.