Belted Cables Explained: Comprehensive Guide with Insights, Facts & Useful Resources

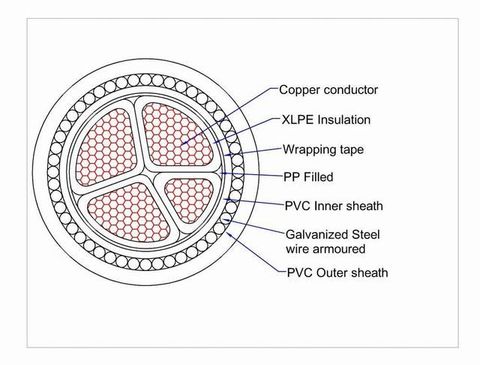

Belted cables are a classification of power cables designed with layers of insulation that surround multiple conductors. These cables are commonly used for medium-voltage electrical distribution systems. Their structure includes separate insulated cores covered by a common insulating belt, which helps manage electrical stress and supports reliable power transmission.

The concept originated during the early development of underground and industrial power networks, where engineers required cables that could handle moderate voltages without excessive dielectric losses. Belted designs offered a solution by adding extra insulation protection to minimize electrical breakdowns.

Today, belted cables remain relevant in many legacy networks and certain industrial environments. Although newer cable technologies have emerged, understanding belted cables is essential for electrical engineering professionals, technicians, safety officers, and planners studying power distribution networks and insulation materials.

Importance

Belted cables contribute to electrical infrastructure reliability, especially in regions where medium-voltage networks continue to use traditional systems. Their importance can be understood through several aspects:

Supports Medium-Voltage Distribution

These cables are typically used for voltages up to around 11 kV. Their layered insulation system helps reduce partial discharges and ensures stable transmission in environments where cable routes may experience temperature changes, moisture, or mechanical stress.

Useful for Industrial Infrastructure

Manufacturing facilities, processing plants, and older energy systems still depend on belted cable installations. Their construction offers structural firmness and straightforward jointing methods, which are beneficial when maintaining existing electrical routes.

Reduces Electrical Stress

The belted insulation adds a uniform dielectric strength across all conductors. This design helps reduce stress concentration, a crucial factor in maintaining long-term cable integrity in power distribution networks.

Relevant in Cable Performance Analysis

Engineers evaluate belted cables when planning upgrades, fault detection assessments, or system extensions. Understanding how the insulation belt interacts with environmental conditions helps in performance forecasting and reliability studies.

Recent Updates

Recent developments in cable technology and electrical standards have influenced how belted cables are used and evaluated:

Shift Toward Modern Insulation (2023–2024)

Many countries and utilities announced transitions from traditional belted cables to cross-linked polyethylene (XLPE) cables starting around 2023. This trend is driven by improved thermal ratings, lower dielectric losses, and longer operational life of XLPE designs.

Increased Focus on Condition Monitoring (2024)

Between January and October 2024, studies in electrical engineering journals highlighted enhanced diagnostic tools such as partial discharge monitoring and thermal imaging for aging belted cable networks. These methods help utilities avoid failures in older installations.

Sustainability Discussions (Late 2024)

Environmental committees and energy agencies reported an increasing emphasis on recyclable cable materials and better insulation design. Although belted cables are older technology, they are frequently included in modernization plans aimed at reducing maintenance-related disruptions.

Digital Mapping Tools in Use (2024)

Several countries adopted digital geographic information systems (GIS) to map underground cable routes. These tools allow engineers to identify sections where older belted cables are still present, aiding in planning safe replacements and inspections.

Laws or Policies

Electrical cables are governed by standards and regulations designed to ensure safe installation, testing, and maintenance. While requirements differ across regions, several categories of policies influence belted cable usage:

National Electrical Codes

Most countries follow a national electrical code that defines acceptable cable types for various voltage levels. Codes typically specify installation methods, insulation ratings, grounding rules, and testing procedures.

Examples include:

-

IEC Standards (International Electrotechnical Commission) for cable construction and performance

-

IS Standards (Indian Standards) for power cables including belted designs

-

BS Standards (British Standards) historically used in many industrial systems

These standards outline conductor size, insulation thickness, permissible temperatures, and fault-withstand capabilities.

Safety Compliance Policies

Government agencies often require:

-

Regular inspection of medium-voltage networks

-

Documentation of insulation condition

-

Use of certified materials in public or industrial infrastructure

Such policies affect how aging belted cables are managed within older grids.

Environmental Regulations

Rules regarding cable disposal and recycling have gained attention. Insulation materials, including paper and compound layers in belted cables, must be handled according to environmental management guidelines.

Infrastructure Upgrade Programs

Many countries operate government-supported modernization programs. These initiatives prioritize replacing older cable types, including traditional belted designs, with modern alternatives that meet updated energy-efficiency objectives.

Tools and Resources

Several tools, references, and platforms help individuals learn, evaluate, or work with belted cables. These are widely used in engineering, planning, and educational environments.

Technical Standards and Documentation

-

IEC Cable Standards Library – Provides engineering documentation for insulation systems

-

IEEE Power Cable Guides – Offers detailed guidelines for testing and analysis

-

National Electrical Code Handbooks – Useful for installation and safety guidance

Diagnostic and Analysis Tools

-

Partial Discharge Testers – Used to identify insulation deterioration

-

Thermal Scanners – Detects temperature fluctuations

-

Cable Route Mapping Software – Helps visualize underground network locations

-

Insulation Resistance Calculators – Assists in performance evaluations

Educational & Research Platforms

-

Engineering research databases for cable performance analysis and insulation materials

-

Online physics and electrical engineering portals for learning cable behavior

-

Open-source simulation tools for modelling electrical stress distribution

Reference Tables for Quick Understanding

Below is a simple table summarizing key characteristics of belted cables:

| Feature | Description |

|---|---|

| Voltage Range | Typically up to 11 kV |

| Insulation Type | Paper-based with protective belting |

| Core Arrangement | Three-core commonly used |

| Applications | Industrial networks, medium-voltage distribution |

| Main Limitation | Not suitable for high-voltage stress conditions |

FAQs

What are belted cables used for?

They are mainly used for medium-voltage power distribution, especially in older or industrial electrical networks. Their insulation design helps manage moderate electrical stress levels.

Why are belted cables less common today?

Modern cable technology, such as XLPE cables, offers improved thermal performance and lower dielectric losses. Many utilities have gradually shifted to newer designs, although belted cables still exist in legacy systems.

What is the main advantage of the belted insulation design?

The insulation belt provides a uniform dielectric layer around multiple conductors, reducing electrical stress concentration and supporting stable operation in medium-voltage systems.

Can belted cables be used for high-voltage applications?

No. Their insulation system is not designed for high-voltage levels due to stress accumulation in the belting layer, which can lead to partial discharge or breakdown.

How are belted cables inspected for faults?

Engineers use methods such as insulation resistance tests, partial discharge detection, thermal scanning, and cable route mapping to identify deterioration or potential failure points.

Conclusion

Belted cables play an important role in medium-voltage distribution systems, especially within older or industrial infrastructure. Understanding their structure, insulation characteristics, and performance limitations is essential for engineers, technicians, and planners working with electrical networks. As technology evolves, belted cables are increasingly assessed alongside modern alternatives, with an emphasis on safety, reliability, and long-term sustainability. With updated diagnostic tools, research resources, and standardized guidelines, the evaluation and management of belted cables continue to improve, supporting more dependable energy transmission across various environments.