A Complete Guide to Industrial Lubricants: Features, Types, and Performance Insights

In industrial operations, smooth performance begins with proper lubrication. Across manufacturing, transportation, food processing, and heavy equipment industries, lubricants play a vital role in machinery longevity and reliability. From reducing wear and tear to improving energy efficiency, the right lubricant can minimize downtime and extend operational life.

Lubrication science has advanced significantly in recent years, with modern formulations designed for high-temperature stability, contamination resistance, and sustainability. Businesses now require precise solutions tailored to specific equipment, industry standards, and environmental expectations.

Brief Overview of Industrial Lubricants

Industrial lubricants are substances—typically oils, greases, or synthetic fluids—that reduce friction between moving machine parts. Their functions include:

-

Minimizing wear and preventing mechanical damage

-

Controlling operating temperature

-

Reducing corrosion and contamination risks

-

Enhancing overall equipment performance

These lubricants are used in a wide range of industries, including manufacturing, agriculture, automotive, energy, and marine. Selecting the right product and applying it properly are essential to achieving efficiency, safety, and durability in industrial systems.

Key Features of Industrial Lubricants

Modern lubricants are engineered with advanced properties to meet demanding conditions.

-

Thermal and oxidation stability: High-temp lubricants retain viscosity and resist breakdown in environments with extreme heat and pressure.

-

Contaminant resistance and longevity: Lubricants designed with strict specifications maintain performance even when exposed to dust, water, or debris.

-

Specialized formulations: From food-grade lubricants for sensitive industries to hydraulic oils and biodegradable options, formulations are tailored for specific needs and compliance standards.

Types of Industrial Lubricants

Different types of lubricants are designed for varied applications and performance expectations.

-

Oils and fluids: Common in hydraulic systems, compressors, and gearboxes. Known for heat transfer capability and smooth operation.

-

Greases: Thickened oils suitable for heavy-duty environments, offering strong load-carrying capacity and resistance to water and contaminants.

-

Synthetic lubricants: Advanced fluids engineered for extreme temperatures and long service intervals, increasingly used in industries requiring durability and efficiency.

Key Applications and Industries

Industrial lubricants are essential across multiple sectors:

-

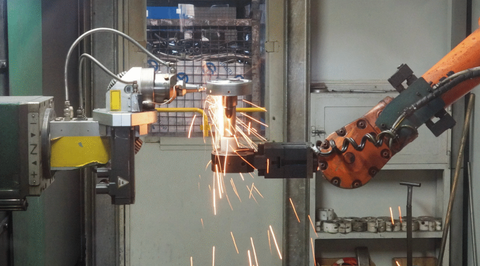

Manufacturing and heavy equipment: Used in machining, forging, and robotics where high performance is needed under heavy loads and elevated temperatures.

-

Food and beverage industry: Food-grade lubricants, certified safe for incidental contact, are used in mixers, conveyors, and packaging equipment.

-

Agriculture, forestry, and marine: Biodegradable lubricants are preferred in eco-sensitive environments to minimize environmental risk.

Benefits of Using the Right Industrial Lubricants

Choosing the correct lubricant offers operational, financial, and environmental advantages:

-

Reduced wear and downtime: Proper lubrication extends machine life and reduces breakdowns.

-

Energy efficiency: Lower friction results in reduced power consumption.

-

Extended maintenance cycles: Synthetic lubricants allow longer intervals between reapplication.

-

Regulatory compliance: Food-grade and eco-friendly lubricants help meet industry safety and environmental standards.

Lubrication Methods in Industrial Settings

The method of application impacts overall performance and safety.

-

Manual application: Tools such as grease guns and brushes apply lubricants in small-scale or precise tasks.

-

Centralized systems: Automated distribution delivers consistent lubrication across multiple machine points.

-

Mist and spray lubrication: Fine sprays used in CNC machining and textiles ensure uniform coverage at high speeds.

Factors to Consider When Choosing Lubricants

Selecting the right lubricant requires careful evaluation of several criteria:

-

Operating conditions: Load, temperature, and speed determine whether high-temp or heavy-duty lubricants are required.

-

Material compatibility: Lubricant chemistry must match seals, metals, and plastics to avoid degradation.

-

Environmental considerations: Regulations increasingly favor biodegradable and low-toxicity lubricants.

Leading Industrial Lubricant Brands

Several well-known companies provide advanced solutions across industries:

-

Shell Lubricants: Offers a wide portfolio, including synthetic fluids for high-load systems.

-

ExxonMobil Lubricants: Known for the Mobil SHC line of synthetic lubricants designed for extended durability.

-

Fuchs Group: Specializes in food-grade and biodegradable lubricants, with a focus on custom solutions.

-

Klüber Lubrication: Renowned for high-performance specialty lubricants, including products for extreme temperatures and eco-sensitive industries.

Safety and Handling Guidelines

Proper safety practices ensure both worker protection and lubricant integrity.

-

Storage: Keep in a cool, dry environment away from direct sunlight to prevent oxidation.

-

Protective equipment: Gloves and goggles are essential to avoid skin and eye contact during application.

-

Disposal: Follow environmental regulations when handling spills or discarding used lubricants. Approved containers and disposal techniques reduce environmental risks.

Trends in Industrial Lubricants

The industry is adapting to modern challenges through innovation and sustainability:

-

Sustainability shift: Biodegradable lubricants are gaining popularity, reducing ecological footprint.

-

Smart lubrication: IoT-enabled systems and sensors track lubricant condition, enabling predictive maintenance.

-

Synthetic advancements: New formulations offer improved oxidation stability, performance across wider temperature ranges, and compatibility with diverse machinery.

Final Thoughts

In the world of industrial operations, lubrication is often the unseen factor driving smooth performance. The right lubricant not only prevents wear but also enhances efficiency, compliance, and sustainability.

From high-temperature synthetic fluids to food-safe and biodegradable options, today’s lubricants are highly specialized. Modern trends like IoT monitoring and eco-friendly formulations continue to redefine the field, ensuring industries can operate with greater reliability and responsibility.