Wave Soldering Machine Overview: Explore Key Facts, Working Process, and Practical Insights

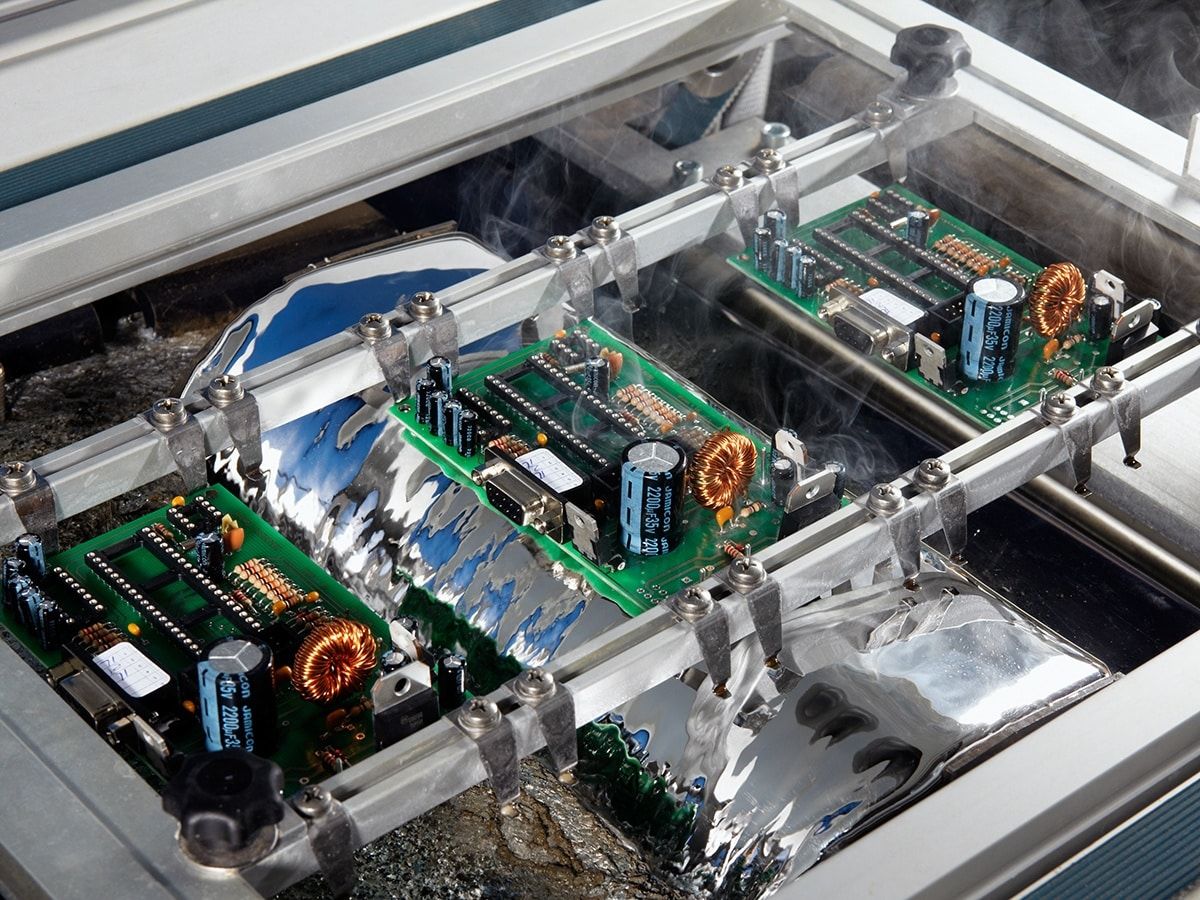

A wave soldering machine is an automated system used in electronics manufacturing to solder many component leads to a printed circuit board (PCB) in one pass.In this process, a conveyor carries the PCB—loaded with through-hole or mixed components—over a bath of molten solder that forms a controlled “wave.” When the board contacts the solder wave, the molten metal adheres to the component leads and pads, creating strong and consistent joints.

This technique emerged because manual soldering was too slow and inconsistent for mass production. Wave soldering provides a fast, uniform, and efficient way to solder multiple joints simultaneously, making it ideal for high-volume PCB manufacturing.

Importance – Why this matters today, who it affects, and what problems it solves

Wave soldering remains essential in modern electronics manufacturing for several reasons:

Efficiency and throughput

-

It allows hundreds of solder joints to be completed in a single operation.

-

It is suitable for high-volume production lines and mixed-technology PCBs.

Quality and reliability

-

When properly controlled, it delivers strong, reliable, and clean solder joints.

-

The process reduces errors and enhances overall product quality, especially for industrial and automotive electronics.

Compatibility with heavy components

-

Many components such as transformers, connectors, or large capacitors still require through-hole soldering.

-

Wave soldering handles these parts better than reflow processes.

Problem solving

-

It eliminates inefficiencies and defects associated with manual soldering.

-

It ensures repeatability and standardization across thousands of units.

Who it affects

-

PCB assembly units and manufacturing engineers.

-

Quality control and process optimization teams.

-

Electronics industries such as automotive, consumer electronics, and power systems.

-

Compliance officers managing manufacturing standards and environmental regulations.

Recent Updates – Changes, trends, or news from the past year

In 2024–2025, wave soldering technology has continued to evolve to meet modern manufacturing demands.

Transition to lead-free soldering

Global environmental awareness and regulations have accelerated the adoption of lead-free solder alloys such as tin-silver-copper (SnAgCu). These alternatives reduce environmental hazards and comply with modern standards but require higher process temperatures and improved control systems.

Technological advancements

-

Modern wave soldering machines feature precise flux application systems, such as ultrasonic spray fluxers, ensuring even distribution and minimal waste.

-

Upgraded pre-heating zones using infrared and convection heating enhance flux activation and reduce thermal shock.

-

Real-time process monitoring, automation, and data collection are now integrated into most advanced systems to ensure consistency and predictive maintenance.

Selective wave soldering

Selective soldering has gained traction as a hybrid solution for PCBs containing both surface-mount and through-hole components. It directs the solder wave only to specific areas, avoiding damage to heat-sensitive parts.

Global manufacturing trends

The electronics manufacturing industry is shifting rapidly toward automation and data-driven production. In regions like India and Southeast Asia, manufacturers are investing in wave soldering machines that meet global environmental and performance standards.

Laws or Policies – How this topic is affected by rules, regulations, or government programs

Wave soldering is significantly shaped by international and national environmental and manufacturing regulations.

Restriction of Hazardous Substances (RoHS)

India, the European Union, and several other countries enforce RoHS directives restricting the use of hazardous materials such as lead, mercury, and cadmium in electronic products. Manufacturers must comply with these limits when designing soldering processes, encouraging the shift toward lead-free soldering.

E-Waste and Environmental Compliance

Under India’s E-Waste (Management) Rules, 2022, manufacturers are required to control the use of hazardous materials and manage waste responsibly. Wave soldering operations must ensure safe handling of solder dross, fumes, and cleaning chemicals.

Worker Safety Regulations

Since wave soldering involves high temperatures and flux vapors, compliance with occupational safety standards is essential. Adequate ventilation, fume extraction systems, and protective gear are required for operator safety.

Quality and Standardization Guidelines

Industry-specific directives emphasize consistent soldering standards, process control, and traceability. Many organizations follow ISO 9001 and IPC-A-610 guidelines for quality assurance in PCB soldering.

Tools and Resources – Helpful tools, software, and references

Professionals involved in electronics manufacturing can use various resources to improve the wave soldering process:

Process control tools

-

Thermal profiling instruments to monitor temperature distribution and solder contact times.

-

Automated inspection systems (AOI) for detecting defects like bridging or insufficient solder.

Reference standards

-

IPC-A-610 for solder joint acceptability.

-

IPC J-STD-001 for soldering process requirements.

Software and digital tools

-

Solder process monitoring software to analyze wave height, conveyor speed, and temperature zones.

-

Data logging applications for real-time performance tracking.

Process optimization templates

-

Checklists for flux application, solder pot maintenance, and wave calibration.

-

Standard operating procedures (SOPs) for machine setup and shutdown.

Educational and training resources

-

Technical webinars, e-learning courses, and virtual demonstrations for operators and engineers.

-

Training modules on lead-free process management and defect reduction.

Frequently Asked Questions (FAQs)

Q1: What types of PCBs are best suited for wave soldering?

Wave soldering works best for through-hole and mixed-technology PCBs where both surface-mount and leaded components are present. It ensures reliable joints and efficient mass production.

Q2: What are the main stages of the wave soldering process?

The typical stages include flux application, pre-heating, soldering (contact with the solder wave), and cooling. Each stage must be optimized to avoid defects such as bridging or insufficient wetting.

Q3: What parameters should be controlled during wave soldering?

Key parameters include solder bath temperature, wave height, conveyor speed, preheat duration, and flux concentration. Monitoring these ensures consistent solder quality.

Q4: How has lead-free soldering affected wave soldering?

Lead-free solders have higher melting points and require better heat control. Machines are now designed with improved temperature regulation, stronger materials for solder pots, and advanced flux chemistry.

Q5: Is wave soldering still relevant in modern electronics?

Yes. Despite the rise of reflow soldering for SMT components, wave soldering remains indispensable for through-hole and hybrid assemblies where strength, reliability, and mass production are key.

Conclusion

The wave soldering machine continues to be a cornerstone in the electronics manufacturing industry. It enables fast, reliable, and uniform soldering for PCBs containing through-hole components or mixed technologies.

With the global push toward automation, data integration, and eco-friendly manufacturing, wave soldering systems are evolving to meet new environmental and process quality standards. Manufacturers adopting lead-free materials, selective soldering, and automated quality control systems are better equipped to maintain high standards and comply with global regulations.

Understanding the principles, process parameters, and regulatory frameworks surrounding wave soldering ensures that electronic products meet both performance and sustainability goals in today’s rapidly advancing manufacturing landscape.