Understanding Carbon Steel Sheets and Their Key Material Benefits

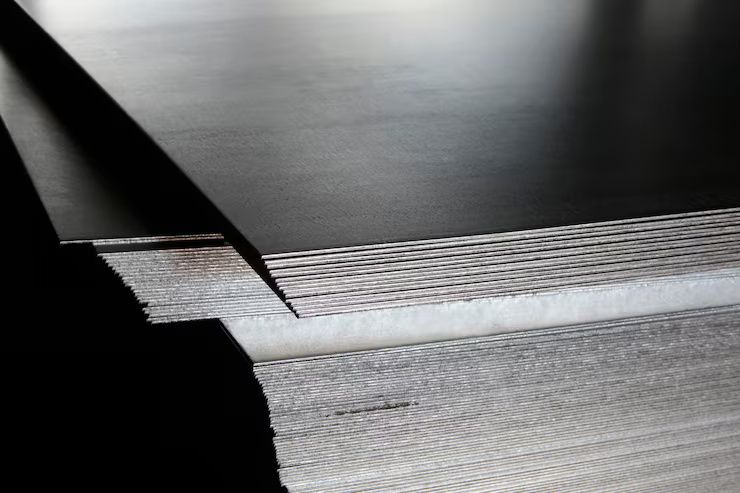

Carbon steel sheets are flat-rolled steel products made primarily from iron and carbon, with small amounts of other elements depending on the grade. The carbon content typically determines the strength, hardness, and flexibility of the steel. These sheets are produced through controlled rolling processes and are available in various thicknesses and sizes for different industrial and commercial uses.

Carbon steel exists because many applications require a balance between strength, durability, and cost. While pure iron is relatively soft, adding carbon increases its strength and hardness, making it suitable for structural, mechanical, and manufacturing purposes. Carbon steel sheets became widely used as industrialization expanded and demand grew for materials that could be formed, welded, and machined efficiently.

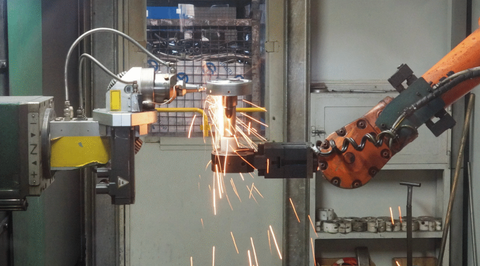

Carbon steel sheets are used in construction, automotive manufacturing, machinery, storage systems, appliances, pipelines, and fabrication work. Their widespread use is linked to their predictable performance and adaptability to different processing methods such as cutting, bending, and welding.

Understanding carbon steel sheets helps users choose materials based on performance requirements rather than assumptions about strength or durability.

Importance

Carbon steel sheets are important because they form the foundation of many industrial and infrastructure systems. Their properties allow them to be used across a wide range of environments and load conditions.

Why this topic matters today

-

Infrastructure and manufacturing demand remains high

-

Cost-effective materials are essential for large projects

-

Standardized steel grades simplify engineering decisions

-

Repair and fabrication industries rely on consistent materials

Carbon steel sheets offer a practical balance between mechanical performance and affordability, which is critical for large-scale applications.

Who carbon steel sheets affect

Carbon steel sheets are relevant for:

-

Construction and infrastructure developers

-

Automotive and transport manufacturers

-

Fabrication and machining workshops

-

Equipment and machinery producers

-

Engineers, architects, and material planners

They also affect supply chains and workforce planning in steel-dependent industries.

Problems carbon steel sheets help address

| Industry Challenge | How Carbon Steel Sheets Help |

|---|---|

| Material cost control | Widely available and economical |

| Structural reliability | Predictable strength properties |

| Fabrication flexibility | Easy forming and welding |

| Standardization | Defined grades and specifications |

| Maintenance planning | Known performance behavior |

By addressing these challenges, carbon steel sheets support stable and scalable industrial operations.

Recent Updates

The carbon steel industry has seen gradual changes over the past year due to technology improvements, sustainability goals, and market demand.

Key developments in the past year

-

2024–2025: Increased focus on low-carbon steel production

Steel producers have been exploring cleaner production methods to reduce emissions during manufacturing. -

2025: Improved surface treatment techniques

Advances in coatings and finishes have helped improve corrosion resistance for carbon steel sheets used in exposed environments. -

Late 2024: Stable demand from infrastructure projects

Public and private construction projects continued to support steady demand for flat steel products. -

Ongoing: Digital quality control systems

Steel mills are using digital monitoring to improve thickness accuracy and consistency.

Industry trend overview

| Area | Recent Trend |

|---|---|

| Production methods | Efficiency improvements |

| Sustainability | Emission reduction focus |

| Quality control | Digital monitoring |

| Demand sectors | Construction and manufacturing |

These updates reflect gradual improvement rather than major changes in material fundamentals.

Laws or Policies

Carbon steel sheet production and usage are influenced by industrial standards, safety regulations, and government policies. In India, several frameworks are relevant.

Relevant laws and standards in India

-

Bureau of Indian Standards (BIS)

Specifies standards for steel grades, dimensions, and mechanical properties. -

National Steel Policy

Supports domestic steel production, quality control, and long-term industry growth. -

Factories Act and Occupational Safety Codes

Regulate safe handling, processing, and storage of steel materials in industrial environments. -

Environmental regulations

Govern emissions, waste management, and energy use in steel manufacturing.

Regulatory impact overview

| Regulation Area | Relevance |

|---|---|

| Material standards | Product consistency |

| Worker safety | Handling and processing |

| Environmental compliance | Sustainable production |

| Trade and supply | Domestic steel support |

These policies help ensure that carbon steel sheets are produced and used responsibly.

Tools and Resources

Several tools and resources help engineers, fabricators, and buyers understand and work with carbon steel sheets effectively.

Helpful tools and services

-

Steel grade charts

Compare carbon content and mechanical properties -

Thickness and weight calculators

Estimate material requirements and load capacity -

Material testing reports

Verify tensile strength and hardness -

Fabrication guides

Support cutting, bending, and welding processes -

Government standards portals

Provide access to BIS and industry guidelines

Common carbon steel sheet categories

| Type | General Characteristics |

|---|---|

| Low carbon steel | Good ductility and weldability |

| Medium carbon steel | Balanced strength and hardness |

| High carbon steel | Higher hardness, lower flexibility |

| Hot-rolled sheets | Rough surface, structural use |

| Cold-rolled sheets | Smooth finish, precision use |

These resources support informed material selection and safe usage.

FAQs

What are carbon steel sheets?

Carbon steel sheets are flat steel products made primarily of iron and carbon, used widely in construction and manufacturing.

How does carbon content affect steel sheets?

Higher carbon content increases strength and hardness but reduces flexibility and weldability.

Are carbon steel sheets corrosion-resistant?

Carbon steel can rust if exposed to moisture. Protective coatings or treatments are often used to improve resistance.

What industries use carbon steel sheets the most?

They are widely used in construction, automotive manufacturing, machinery, appliances, and fabrication industries.

Are carbon steel sheets recyclable?

Yes. Carbon steel is fully recyclable and commonly reused in new steel production.

Final Thoughts

Carbon steel sheets remain one of the most widely used materials in modern industry due to their balance of strength, availability, and adaptability. Their predictable behavior and standardized grades make them suitable for a wide range of applications, from large infrastructure projects to precision manufacturing.

While newer materials continue to emerge, carbon steel sheets continue to play a central role because they meet practical needs at scale. Understanding their properties, benefits, and limitations helps engineers, builders, and planners make informed decisions based on performance requirements rather than assumptions.

As production methods evolve and sustainability efforts expand, carbon steel sheets are expected to remain a reliable and essential material in industrial and structural applications for years to come.