Guide to Choosing the Best Glass Cutting Machine

Glass cutting machines are specialized tools designed to shape, trim, or engrave glass sheets with precision. They exist because manual glass cutting is often inaccurate, time-consuming, and prone to breakage. Industrial and professional sectors—from architecture to automotive manufacturing—require reliable machines to ensure precision in complex glass designs.

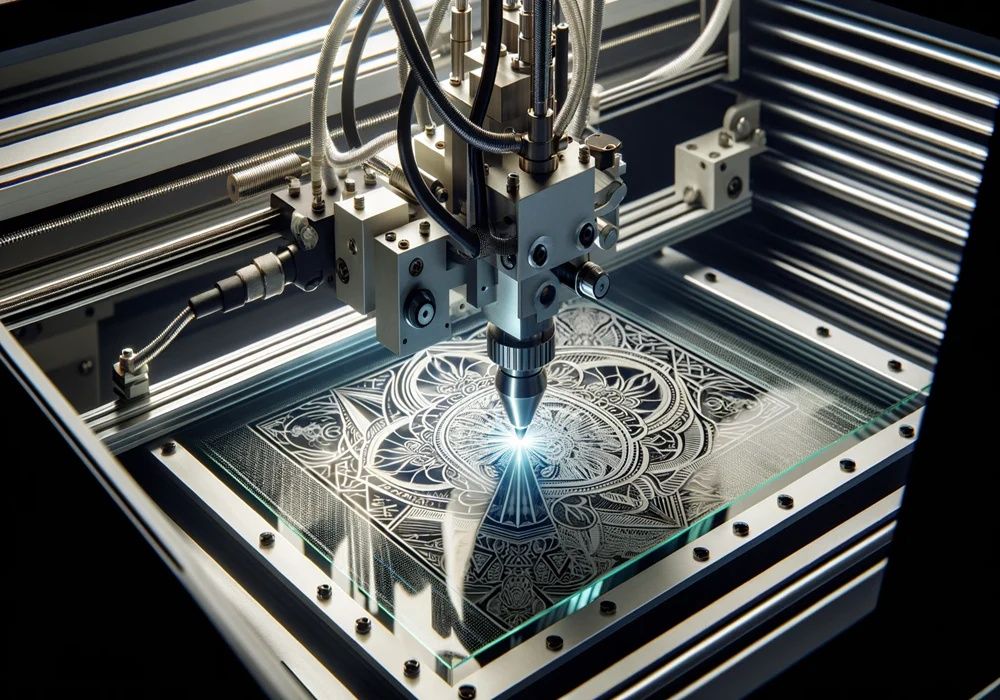

These machines come in different types, including manual cutters for simple operations, CNC (computer numerical control) systems for complex shapes, and laser-based machines for high-precision applications. The choice depends on the type of glass, the level of detail required, and the intended use.

Importance

Glass cutting machines are vital in many industries and applications. Their importance lies in:

-

Precision and efficiency: Machines reduce material waste and deliver consistent results.

-

Safety: Modern machines incorporate safety features that minimize risks during cutting.

-

Innovation in design: Enables architects, artists, and manufacturers to create intricate patterns and custom shapes.

-

Support for mass production: Automated machines can cut large volumes of glass quickly, which is essential for construction and automotive sectors.

This topic matters for industries such as construction, furniture design, electronics, solar panel manufacturing, and interior decoration. For individuals and companies, choosing the right machine solves the problem of balancing accuracy, efficiency, and long-term reliability.

Recent Updates

The glass cutting industry has seen rapid advancements over the past year (2024–2025). Key developments include:

-

Smart automation (2024): Machines integrated with IoT sensors now monitor cutting speed, temperature, and blade wear, improving predictive maintenance.

-

Laser precision (2025): Laser-based cutting technologies are gaining popularity for thin and specialty glass, offering minimal edge damage.

-

Eco-friendly systems (2024): Waterjet cutting with recyclable water systems is being adopted to reduce environmental impact.

-

Integration with CAD/CAM software (2025): Direct connection between design software and cutting machines allows seamless transitions from design to production.

-

Customization in architecture (2025): Growing demand for bespoke glass designs in modern buildings has increased the need for advanced machines.

Reports from industry analysts suggest the market will continue to grow steadily, driven by smart construction projects and renewable energy sectors like solar.

Laws or Policies

Glass cutting is influenced by safety and environmental regulations worldwide. These policies aim to ensure worker protection, product quality, and sustainable practices. Examples include:

-

OSHA Standards (United States): Regulate workplace safety during cutting, handling, and processing of glass materials.

-

European Machinery Directive: Sets safety requirements for machines used in the EU, including glass cutting equipment.

-

ISO Standards for Glass Products: Provide international quality benchmarks for glass processing and manufacturing.

-

Environmental policies: In many countries, laws encourage water recycling and dust control in glass cutting processes.

-

Building codes: National and local building regulations often specify the quality and safety of glass used in construction, indirectly affecting machine requirements.

These policies ensure machines are designed and operated in ways that protect workers, consumers, and the environment.

Tools and Resources

Several resources can help users understand and select the right glass cutting machine:

-

CAD/CAM software: Programs like AutoCAD or SolidWorks integrate directly with CNC glass cutting machines.

-

Online calculators: Tools for estimating cutting speed, pressure, and optimal blade choice based on glass thickness.

-

Simulation platforms: Software that models the cutting process before production begins, reducing errors.

-

Educational resources: Engineering institutions and technical platforms provide tutorials on machine operation and safety.

-

Standards databases: Websites like ISO.org or ANSI.org provide access to technical guidelines for glass machinery.

FAQs

What types of glass cutting machines are available?

Options include manual cutters, CNC-based machines, waterjet systems, and laser cutters. Each type is suited to different precision and volume requirements.

How does a CNC glass cutting machine work?

CNC machines use computer-controlled movements to cut glass into exact shapes and dimensions. They are programmed through CAD/CAM software for high accuracy.

Why is laser cutting popular for thin glass?

Laser cutting minimizes edge cracking and produces cleaner cuts, making it ideal for thin, delicate, or specialty glass types such as used in electronics.

Are there environmental considerations with glass cutting?

Yes. Waterjet machines often recycle water, and modern systems are designed to reduce dust, noise, and waste, helping meet environmental standards.

What industries use glass cutting machines the most?

Construction, automotive, furniture design, solar energy, and electronics are among the sectors most reliant on advanced glass cutting technology.

Conclusion

Choosing the best glass cutting machine requires understanding the context, importance, and innovations shaping this field. With advancements in CNC automation, laser precision, and eco-friendly cutting methods, industries now have greater flexibility and efficiency in glass processing.

By aligning machine selection with industry needs, safety standards, and environmental policies, decision-makers can ensure long-term productivity and innovation. Glass cutting technology continues to evolve, making it an integral part of modern manufacturing, architecture, and design.