Explore Soldering Machines: A Complete Guide with Basics, Facts, and Practical Information

Soldering machines are industrial and electronic manufacturing tools used to permanently join metal components using a filler material known as solder. This process creates reliable electrical and mechanical connections, particularly in electronic circuits and metal assemblies. Unlike temporary fastening methods, soldering provides stable conductivity and structural integrity.

The concept of soldering dates back centuries, but modern soldering machines emerged with the rise of electrical engineering, printed circuit boards (PCBs), and automated manufacturing. As electronic devices became smaller and more complex, manual soldering was no longer sufficient for precision and consistency. Machines were developed to improve accuracy, speed, repeatability, and safety in production environments.

Today, soldering machines are used across electronics manufacturing, automotive electronics, aerospace systems, industrial controls, renewable energy equipment, and telecommunications hardware.

Why Soldering Machines Matter in Modern Manufacturing

Soldering machines play a critical role in ensuring that electronic and electrical systems function reliably. Poor solder joints can cause circuit failure, overheating, signal loss, or complete device malfunction. As technology becomes more integrated into daily life, the reliability of soldered connections becomes increasingly important.

This topic matters today because soldering machines:

-

Support high-precision electronic assembly

-

Enable consistent quality across large production volumes

-

Reduce defects caused by human error

-

Improve durability of electrical connections

-

Support miniaturization of electronic components

-

Help meet strict quality and safety standards

Industries affected include electronics manufacturing, industrial automation, electric mobility, consumer electronics, medical devices, and energy systems. Engineers, quality controllers, technicians, and production planners all depend on soldering technology to ensure long-term product performance.

Soldering machines also solve challenges such as uneven joints, thermal damage, weak conductivity, and inconsistent bonding that may occur with manual techniques.

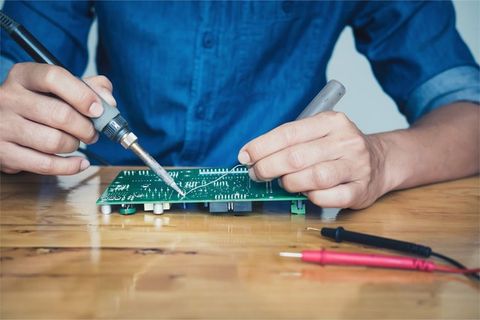

How Soldering Machines Function in Practice

Soldering machines operate by heating solder material to a controlled temperature and applying it precisely to the joint area. Once cooled, the solder solidifies and forms a conductive bond between components.

Common operating steps include:

-

Preparation of components and circuit surfaces

-

Controlled heating using thermal elements or infrared systems

-

Application of solder through wave, paste, or wire methods

-

Cooling and solidification of joints

-

Inspection for joint integrity and alignment

Different machines use different soldering methods depending on application requirements, production volume, and component sensitivity.

Table: Common Types of Soldering Machines and Their Use

| Machine Type | Primary Application | Key Characteristic |

|---|---|---|

| Wave Soldering Machine | Through-hole PCB assembly | Suitable for bulk production |

| Reflow Soldering System | Surface-mount components | High precision temperature control |

| Selective Soldering Machine | Mixed PCB designs | Targets specific joints |

| Robotic Soldering System | Automated assembly lines | High repeatability |

| Laser Soldering Machine | Micro-electronics | Localized heat control |

Recent Updates and Industry Developments

Over the past year, soldering technology has continued to evolve in response to electronics miniaturization, sustainability goals, and advanced manufacturing practices.

Notable developments observed during 2025–2026 include:

-

Increased adoption of automated soldering machines in PCB assembly lines

-

Expanded use of lead-free soldering processes aligned with environmental regulations

-

Improvements in thermal profiling software for reflow soldering accuracy

-

Integration of AI-based inspection systems to detect solder defects

-

Greater focus on energy-efficient heating elements

-

Wider implementation of Industry 4.0 monitoring in soldering workflows

These trends reflect a shift toward smarter, cleaner, and more precise soldering operations that align with modern manufacturing expectations.

Regulatory and Policy Considerations Affecting Soldering Machines

Soldering machines are influenced by industrial safety, environmental, and quality regulations. While exact rules vary by country, common regulatory areas apply globally.

Key regulatory considerations include:

-

Restrictions on hazardous substances in electronic manufacturing

-

Occupational safety rules regarding heat exposure and fumes

-

Electrical safety standards for industrial equipment

-

Environmental compliance for solder materials and waste handling

-

Quality standards for electronic assemblies used in critical systems

In many regions, lead-free soldering requirements have reshaped machine design and temperature control capabilities. Compliance with international standards such as IPC guidelines and ISO quality frameworks is often necessary in regulated industries.

These regulations exist to protect workers, ensure product safety, and reduce environmental impact.

Tools, Resources, and Knowledge References

Understanding and operating soldering machines effectively requires access to technical tools and educational resources. Several tools support accurate soldering operations and quality control.

Helpful resources include:

-

Thermal profiling tools for soldering temperature optimization

-

PCB design compatibility guides for soldering processes

-

Solder joint inspection charts and defect reference guides

-

Digital monitoring dashboards for automated soldering systems

-

Industry standards documentation for electronic assembly

-

Training manuals for soldering best practices

-

Process validation templates for manufacturing audits

These tools help engineers and technicians maintain consistent quality and adapt to evolving production requirements.

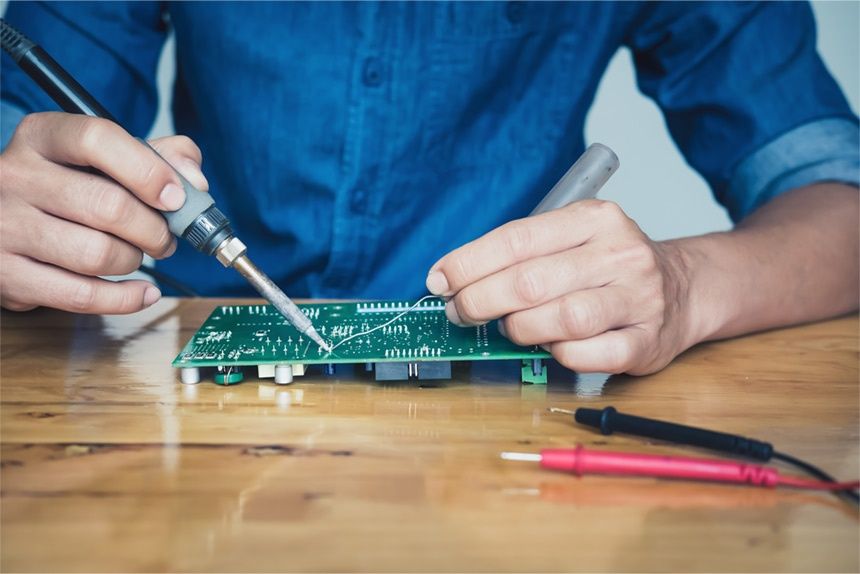

Practical Insights and Operational Knowledge

Effective soldering machine use depends on both technology and process discipline. Even advanced systems require proper setup, monitoring, and understanding of materials.

Helpful insights include:

-

Maintaining accurate temperature profiles to avoid cold or overheated joints

-

Matching solder type with component material and PCB design

-

Regular calibration of heating zones and sensors

-

Monitoring solder flow consistency and oxidation levels

-

Ensuring clean surfaces before solder application

-

Reviewing inspection data to identify recurring joint issues

Practical knowledge reduces rework, improves yield rates, and enhances long-term system reliability.

Table: Common Soldering Defects and Observations

| Defect Type | Typical Cause | Observed Impact |

|---|---|---|

| Cold Solder Joint | Insufficient heat | Weak electrical connection |

| Bridging | Excess solder | Short circuits |

| Voids | Trapped gases | Reduced strength |

| Lifted Pads | Excess heat | PCB damage |

| Incomplete Wetting | Contamination | Poor conductivity |

Frequently Asked Questions

What is the primary purpose of a soldering machine?

A soldering machine creates durable electrical and mechanical connections between metal components using controlled heat and solder material.

How is machine soldering different from manual soldering?

Machine soldering offers higher precision, repeatability, and consistency, making it suitable for large-scale and complex assemblies.

Are soldering machines only used for electronics?

While electronics are the primary application, soldering machines are also used in automotive components, industrial controls, and energy equipment.

Why is temperature control important in soldering?

Correct temperature ensures proper solder flow without damaging components or weakening joints.

What factors influence solder joint quality?

Material compatibility, heat control, surface cleanliness, solder composition, and process consistency all influence joint quality.

Conclusion

Soldering machines are foundational tools in modern manufacturing, enabling reliable electrical connections across countless devices and systems. From simple circuit boards to advanced industrial electronics, soldering technology ensures that components function as intended over time.

As manufacturing standards rise and electronic designs become more compact, soldering machines continue to evolve through automation, precision control, and digital monitoring. Understanding how these machines work, why they matter, and how regulations and tools shape their use provides valuable knowledge for anyone involved in technical production or engineering environments.

With proper operation, monitoring, and process awareness, soldering machines remain a dependable backbone of electronic assembly and industrial innovation.