Explore an Informational Guide to Advanced Materials Shaping Modern Industry

Advanced materials refer to engineered substances designed to deliver improved performance compared to traditional materials such as steel, concrete, or basic plastics. These materials are developed to meet modern industrial requirements like higher strength, lighter weight, better thermal resistance, electrical conductivity, or environmental durability.

The development of advanced materials exists because conventional materials often reach physical or chemical limits. As industries evolved especially manufacturing, electronics, energy, construction, and transportation there was a growing need for materials that could operate reliably under extreme conditions while improving efficiency and precision.

Common categories include composites, smart materials, nanomaterials, biomaterials, and high-performance alloys. Each category addresses specific industrial challenges by combining scientific knowledge with engineering innovation.

Why Advanced Materials Matter Today

Advanced materials play a critical role in shaping how modern industries function and grow. They directly influence productivity, sustainability, safety, and technological advancement across multiple sectors.

Industries affected include:

-

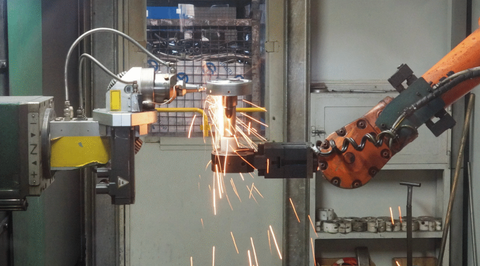

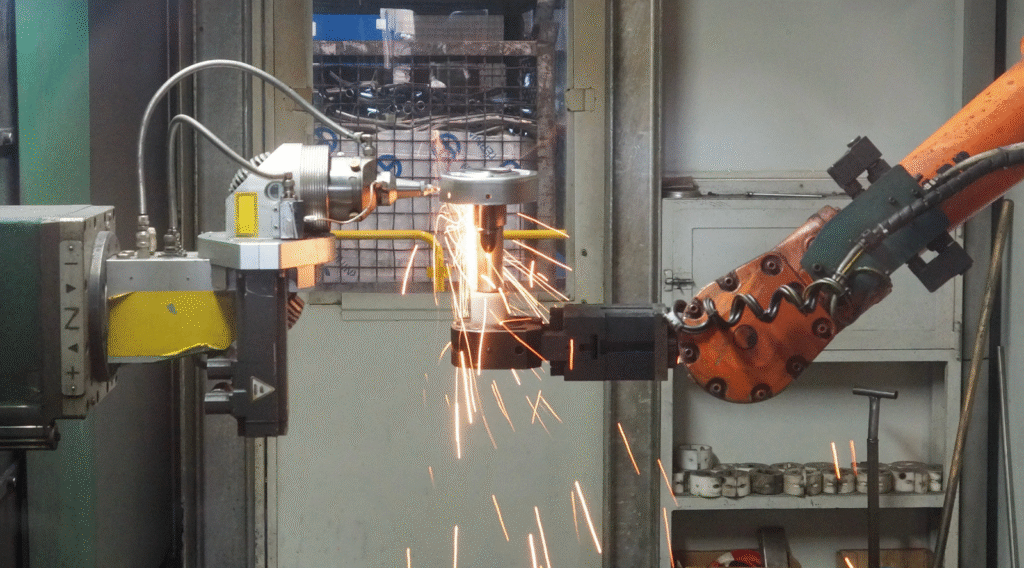

Manufacturing and industrial automation

-

Aerospace and transportation

-

Electronics and semiconductors

-

Energy generation and storage

-

Healthcare and medical devices

Key problems addressed by advanced materials include material fatigue, excessive energy consumption, equipment failure, and limited product lifespan. For example, lightweight composites help reduce energy usage in transportation systems, while heat-resistant alloys improve reliability in power generation environments.

From an economic perspective, advanced materials support innovation-driven growth by enabling new product designs and manufacturing processes. From an environmental standpoint, they contribute to reduced waste, improved recyclability, and better resource utilization.

Recent Developments and Industry Trends

Over the past year, the advanced materials field has seen notable developments driven by research investment, sustainability goals, and digital manufacturing technologies.

Key updates and trends observed since 2025 include:

-

Increased adoption of recyclable composites in automotive and infrastructure projects

-

Growth in nanomaterial research for electronics and energy storage applications

-

Expanded use of additive manufacturing-compatible materials

-

Strong focus on low-emission and energy-efficient material development

In mid-2025, several global research initiatives emphasized materials designed for circular economy models. These initiatives highlighted materials that maintain performance while allowing easier recovery and reuse.

Another trend is the integration of artificial intelligence in materials discovery. Data-driven simulations are helping researchers predict material behavior faster than traditional testing methods, reducing development cycles and improving reliability.

Regulatory Environment and Policy Influence

Advanced materials are influenced by safety standards, environmental regulations, and government-supported research programs. In India, industrial material development aligns with national initiatives that promote manufacturing excellence, sustainability, and innovation.

Relevant policy frameworks include:

-

Industrial safety standards governing material strength and durability

-

Environmental compliance norms related to emissions and recyclability

-

National research programs supporting advanced manufacturing technologies

Government-supported research institutions and public-private partnerships play a key role in testing, validating, and standardizing advanced materials. Regulatory oversight ensures that new materials meet safety, performance, and environmental benchmarks before large-scale adoption.

These policies help balance innovation with public safety and environmental responsibility, encouraging responsible industrial growth.

Practical Tools and Learning Resources

Understanding advanced materials requires access to reliable tools, reference platforms, and educational resources. These resources support learning, analysis, and informed decision-making.

Commonly used tools and resources include:

-

Material property databases for mechanical and thermal data

-

Simulation software for material behavior analysis

-

Industry white papers and technical publications

-

Academic research portals and journals

-

Government-supported innovation platforms

| Resource Type | Purpose | Typical Users |

|---|---|---|

| Material Databases | Compare properties and performance | Engineers, researchers |

| Simulation Platforms | Predict stress, heat, and fatigue behavior | Design teams |

| Research Journals | Access peer-reviewed studies | Academics, analysts |

| Standards Documentation | Understand compliance requirements | Manufacturers |

These tools help bridge the gap between theoretical knowledge and real-world application, making advanced materials more accessible to a broader audience.

Common Questions About Advanced Materials

What makes a material “advanced” rather than traditional?

Advanced materials are engineered to deliver enhanced or specialized performance that traditional materials cannot achieve under similar conditions.

Are advanced materials limited to high-tech industries?

No. While commonly associated with high-tech sectors, advanced materials are also widely used in construction, energy systems, and industrial equipment.

How do advanced materials support sustainability?

Many advanced materials are designed to reduce energy consumption, extend product lifespan, and support recycling or reuse.

Do advanced materials replace traditional materials completely?

In most cases, they complement rather than replace traditional materials, depending on performance requirements and application conditions.

Is specialized knowledge required to work with advanced materials?

Yes. Proper application often requires technical understanding of material properties, testing standards, and operational conditions.

Comparison of Major Advanced Material Categories

| Material Category | Key Characteristics | Common Applications |

|---|---|---|

| Composites | Lightweight, high strength | Transportation, construction |

| Nanomaterials | Enhanced electrical and thermal properties | Electronics, energy storage |

| Smart Materials | Responsive to external stimuli | Sensors, automation |

| High-Performance Alloys | Heat and corrosion resistance | Power systems, aerospace |

| Biomaterials | Biocompatibility and durability | Medical devices |

This comparison highlights how different material classes address distinct industrial requirements.

Concluding Insights

Advanced materials represent a foundational element of modern industrial progress. They exist to overcome the limitations of conventional materials and enable safer, more efficient, and more sustainable systems across industries.

As technology continues to evolve, advanced materials will remain central to innovation in manufacturing, energy, transportation, and beyond. Ongoing research, supportive policy frameworks, and accessible learning resources are helping expand understanding and adoption globally.

For readers seeking clear, factual knowledge, advanced materials offer a compelling example of how science and engineering intersect to shape the modern industrial landscape. This guide provides a foundational overview, practical insights, and reliable information to support continued learning and informed exploration.