Expert Guide to Bucket Elevators for Smooth Vertical Transport

Bucket elevators are mechanical systems used to transport bulk materials vertically. They consist of buckets attached to a belt or chain that moves material upward inside a casing. Bucket elevators exist because many industries need an efficient way to lift materials such as grains, cement, sand, fertilizers, coal, or food ingredients from a lower level to a higher one.

Before bucket elevators were developed, vertical material handling relied heavily on manual labor or inefficient conveying methods. These approaches were slow, unsafe, and inconsistent. As industrial production increased, especially in agriculture, mining, and manufacturing, there was a clear need for a reliable and continuous vertical transport solution.

Bucket elevators were designed to address this need by providing controlled, enclosed, and steady lifting of bulk materials. Today, they are widely used in processing plants, storage facilities, ports, and factories where vertical movement is essential to workflow efficiency.

Importance – Why Bucket Elevators Matter Today

Bucket elevators remain a critical part of modern material handling systems. Their importance extends across industries that rely on safe, efficient, and continuous vertical transport.

Efficient Vertical Material Movement

Bucket elevators are specifically designed for lifting materials vertically, which conveyor belts or screw conveyors cannot do efficiently over large heights.

Reduced Material Loss

The enclosed structure of bucket elevators minimizes spillage and dust generation, helping maintain material quality and cleaner work environments.

High Capacity Handling

Bucket elevators can move large volumes of material consistently, making them suitable for both small-scale and large-scale industrial operations.

Improved Workplace Safety

Automation reduces the need for manual lifting, lowering the risk of worker injuries and improving overall safety.

Versatility Across Industries

Bucket elevators are used in many sectors, including:

-

Agriculture and grain storage

-

Cement and construction materials

-

Mining and minerals processing

-

Food and beverage production

-

Chemical and fertilizer plants

Supports Continuous Production

By integrating smoothly into processing lines, bucket elevators help maintain steady production flow without frequent interruptions.

These benefits make bucket elevators essential for industries that depend on reliable vertical transport systems.

Recent Updates – Developments and Trends in 2024–2025

The bucket elevator industry has seen steady improvements over the past year, focusing on efficiency, durability, and smart monitoring.

Increased Use of High-Strength Materials (2024)

Manufacturers introduced improved belts, chains, and buckets made from wear-resistant materials, extending equipment lifespan.

Energy-Efficient Drive Systems

New motor and gearbox designs released in 2024 help reduce power consumption while maintaining lifting capacity.

Smart Monitoring and Sensors (2024–2025)

Modern bucket elevators now include sensors that monitor belt alignment, speed, temperature, and load. These systems help prevent breakdowns and unplanned downtime.

Improved Dust Control Designs

Enhanced sealing and casing designs introduced in 2024 help control dust emissions, supporting cleaner and safer operations.

Compact and Modular Elevator Designs

Manufacturers developed modular bucket elevators that are easier to install and maintain, especially in space-limited facilities.

Focus on Low-Maintenance Solutions

Design improvements reduced lubrication needs and simplified inspection processes, lowering maintenance effort and costs.

These trends reflect the industry’s shift toward reliability, sustainability, and predictive maintenance.

Laws or Policies – Regulations Affecting Bucket Elevator Operations

Bucket elevators are subject to various safety, environmental, and industrial regulations to ensure safe and responsible operation.

Workplace Safety Regulations

Industrial safety authorities require:

-

Proper guarding of moving parts

-

Emergency stop mechanisms

-

Safe access for inspection and maintenance

-

Operator training

These rules help prevent accidents and equipment misuse.

Dust and Explosion Prevention Standards

In industries handling combustible materials such as grain or powders, regulations often require:

-

Dust control systems

-

Explosion vents or suppression systems

-

Proper grounding and electrical safety

These standards are critical for risk reduction.

Equipment Certification and Compliance

Bucket elevators must meet mechanical and electrical standards related to:

-

Structural strength

-

Load capacity

-

Noise limits

-

Electrical safety

Certification ensures suitability for industrial environments.

Environmental Protection Policies

Regulations may address:

-

Dust emissions

-

Noise pollution

-

Waste material handling

Modern bucket elevator designs support compliance through enclosed systems and efficient drives.

Industry-Specific Guidelines

Sectors such as food processing and pharmaceuticals require hygienic designs, including easy-to-clean surfaces and food-grade materials.

These policies ensure bucket elevators operate safely and responsibly across different industries.

Tools and Resources – Helpful Platforms and Applications

Several tools and resources support the selection, operation, and maintenance of bucket elevator systems.

Useful Tools and Resources

| Tool / Resource | Purpose / Benefit |

|---|---|

| Capacity Calculation Tools | Estimate material flow rates and bucket size requirements. |

| Maintenance Management Software | Schedule inspections and preventive maintenance. |

| Belt and Chain Selection Guides | Help choose suitable components based on load and material type. |

| Condition Monitoring Systems | Detect misalignment, overheating, or speed issues early. |

| Safety Compliance Checklists | Ensure elevators meet regulatory requirements. |

| Material Handling Standards Portals | Provide industry guidelines and best practices. |

| Training Resources for Operators | Improve safe operation and troubleshooting skills. |

| Energy Consumption Trackers | Monitor and optimize power usage. |

These tools help improve reliability, efficiency, and compliance in bucket elevator operations.

FAQs – Clear and Factual Answers

What is the main function of a bucket elevator?

A bucket elevator transports bulk materials vertically from one level to another in a controlled and continuous manner.

What materials can be handled by bucket elevators?

They can handle grains, powders, granules, minerals, cement, sand, and various industrial bulk materials.

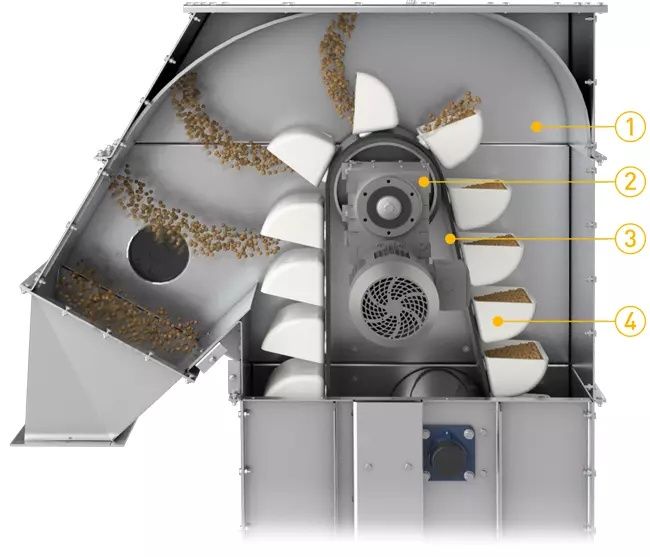

What are the main types of bucket elevators?

Common types include centrifugal discharge, continuous discharge, belt bucket elevators, and chain bucket elevators.

How often do bucket elevators need maintenance?

Maintenance frequency depends on usage, but regular inspection of belts, buckets, bearings, and drive systems is recommended.

Are bucket elevators energy efficient?

Modern bucket elevators are designed to be energy efficient, especially when equipped with optimized motors and smart control systems.

Final Thoughts

Bucket elevators play a vital role in modern material handling by enabling smooth, efficient, and safe vertical transport. Their enclosed design, high capacity, and adaptability make them suitable for a wide range of industries. Recent advancements in materials, monitoring technology, and energy efficiency continue to improve their performance and reliability. By understanding how bucket elevators work, the regulations that govern them, and the tools available to support their operation, businesses and operators can make informed decisions that enhance productivity and long-term system reliability.