Discover How CNC Punch Press Machines Improve Precision and Speed

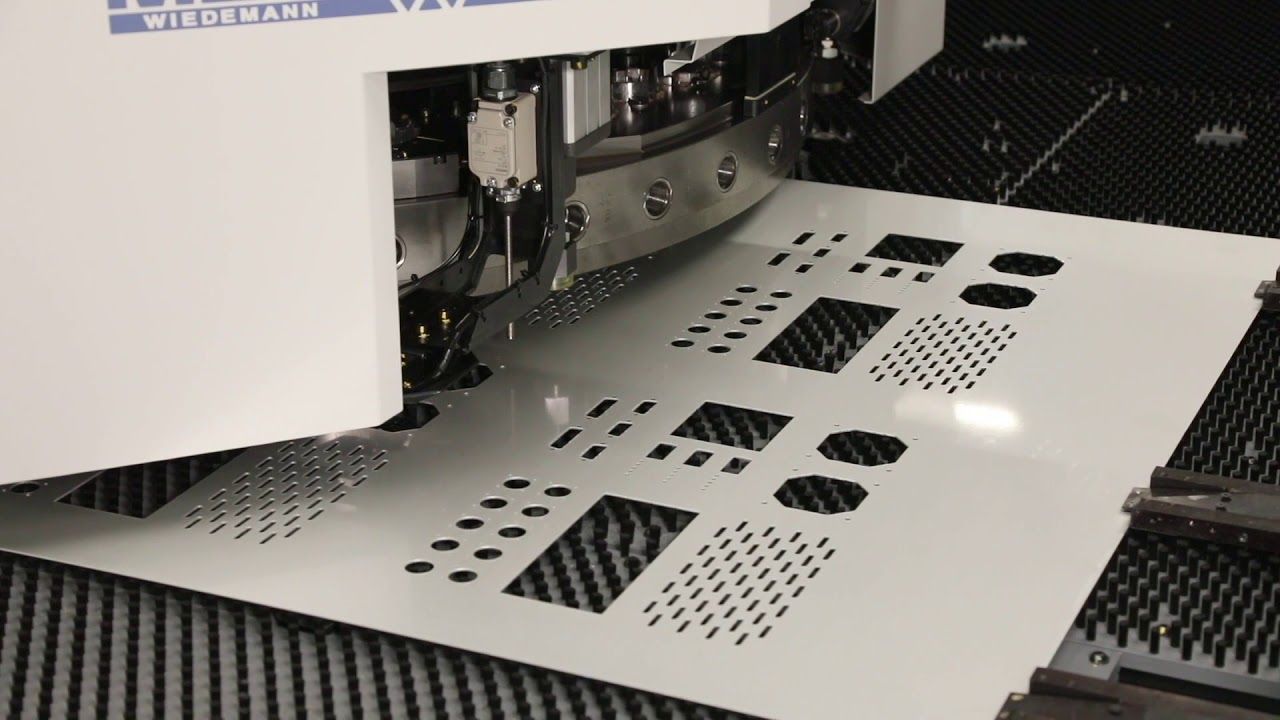

CNC punch press machines are computer-controlled manufacturing tools used to punch holes, shapes, and patterns into sheet metal. The term CNC stands for Computer Numerical Control, meaning the machine follows programmed instructions to perform precise and repeatable operations. These machines exist because traditional manual punching methods were slow, inconsistent, and highly dependent on operator skill.

As manufacturing expanded into industries such as automotive, electronics, construction, and appliance production, there was a growing need for faster and more accurate metal fabrication. CNC punch press machines were developed to meet this need by combining mechanical punching with digital control systems. This allowed manufacturers to produce complex designs with consistent accuracy at higher speeds.

Modern CNC punch presses can handle a wide range of materials, including steel, aluminum, copper, and stainless steel. They support automated workflows, reduce manual intervention, and integrate easily into modern production environments.

Importance – Why CNC Punch Press Machines Matter Today

CNC punch press machines play an important role in today’s manufacturing and fabrication sectors. They influence productivity, quality, and cost efficiency across many industries.

Improved Precision and Accuracy

Computer-controlled operations ensure that every punch is placed exactly according to the design file. This reduces dimensional errors and improves overall product quality.

Higher Production Speed

CNC punch presses can perform multiple punching operations in a short time. Automated tool changes and programmed sequences help maintain fast and consistent output.

Reduced Material Waste

Precise punching minimizes scrap and optimizes material usage. Efficient nesting of parts helps manufacturers get more components from each metal sheet.

Consistency Across Large Batches

Once a program is set, the machine can repeat the same operation thousands of times without variation. This is essential for mass production and quality assurance.

Lower Dependence on Manual Labor

Automation reduces the need for constant operator involvement. This helps lower physical strain on workers and reduces the risk of human error.

Wide Range of Applications

CNC punch press machines are used in:

-

Electrical panels and enclosures

-

Automotive components

-

HVAC ducting

-

Metal furniture

-

Industrial cabinets

These advantages make CNC punch presses essential for manufacturers aiming to balance speed, precision, and efficiency.

Recent Updates – Trends and Developments in 2024–2025

The past year has brought several advancements in CNC punch press technology, reflecting broader trends in smart manufacturing and automation.

Integration of Smart Monitoring Systems (2024–2025)

Many CNC punch presses now include sensors and digital dashboards that monitor machine performance, tool wear, and production output in real time.

Improved Energy Efficiency

Manufacturers introduced energy-efficient drives and motors in 2024, helping reduce electricity consumption without compromising performance.

Hybrid Punching and Forming Capabilities

New models released in 2024 support both punching and forming operations in a single setup. This reduces secondary processing steps.

Enhanced Software Interfaces

Updated CNC software features improved user interfaces, making programming easier and reducing setup time for new jobs.

Automation and Material Handling

Robotic sheet loading and unloading systems became more common in 2024, enabling continuous operation and reducing downtime.

Focus on Compact and Flexible Designs

Smaller CNC punch press models were introduced for workshops with limited space, supporting flexible manufacturing needs.

These updates show a shift toward smarter, more efficient, and adaptable metal fabrication solutions.

Laws or Policies – Regulations Affecting CNC Punch Press Operations

CNC punch press machines operate within regulatory frameworks that ensure safety, quality, and environmental responsibility.

Workplace Safety Regulations

Manufacturing facilities must comply with occupational safety standards, including:

-

Machine guarding

-

Emergency stop systems

-

Operator training requirements

These rules help prevent accidents and injuries.

Equipment Certification Standards

CNC machines often need to meet national and international standards for:

-

Electrical safety

-

Mechanical reliability

-

Noise limits

Certification ensures machines are safe for industrial use.

Environmental Compliance

Regulations may cover:

-

Energy efficiency

-

Noise pollution

-

Waste management

Manufacturers are encouraged to use energy-efficient machines and reduce scrap.

Industry Quality Standards

Products manufactured using CNC punch presses often need to meet industry-specific standards, especially in automotive and electrical sectors.

Government Support for Automation

In some regions, government programs encourage adoption of CNC technology through training initiatives or manufacturing modernization schemes.

These policies support safe operation while promoting efficient and sustainable manufacturing practices.

Tools and Resources – Helpful Platforms and Applications

Manufacturers and operators can use various tools to optimize CNC punch press operations and improve production planning.

Useful Tools and Resources

| Tool / Resource | Purpose / Benefit |

|---|---|

| CAD/CAM Software | Design parts and generate CNC programs. |

| Punch Tool Selection Guides | Help choose the right tooling for specific materials. |

| Production Monitoring Software | Track machine usage, downtime, and output. |

| Maintenance Management Systems | Schedule servicing and prevent breakdowns. |

| Material Utilization Calculators | Optimize sheet layout to reduce waste. |

| Operator Training Platforms | Improve machine handling and safety knowledge. |

| Quality Control Checklists | Ensure consistent product standards. |

| Industry Standards Portals | Provide guidelines for metal fabrication compliance. |

These tools support accuracy, efficiency, and long-term equipment reliability.

FAQs – Clear and Factual Answers

What does a CNC punch press machine do?

A CNC punch press machine punches holes and shapes into sheet metal using programmed instructions, ensuring precision and consistency.

How does CNC punching improve speed?

Automation allows multiple operations to run continuously without manual adjustments, significantly increasing production speed.

What materials can be processed with CNC punch presses?

Common materials include steel, aluminum, stainless steel, and copper, depending on machine capacity and tooling.

Do CNC punch press machines require skilled operators?

Basic training is required, but modern interfaces simplify operation and programming, making them accessible to a wider workforce.

How often do CNC punch presses need maintenance?

Routine maintenance depends on usage but typically includes tool inspection, lubrication, and software checks to ensure smooth operation.

Final Thoughts

CNC punch press machines have transformed metal fabrication by delivering higher precision, faster production speeds, and consistent quality. Their ability to automate complex punching tasks makes them valuable across many manufacturing industries. Recent advancements in smart monitoring, energy efficiency, and automation continue to enhance their role in modern factories. By understanding how CNC punch press machines work, the regulations that guide their use, and the tools that support their operation, manufacturers and operators can make informed decisions that support efficient and reliable production.