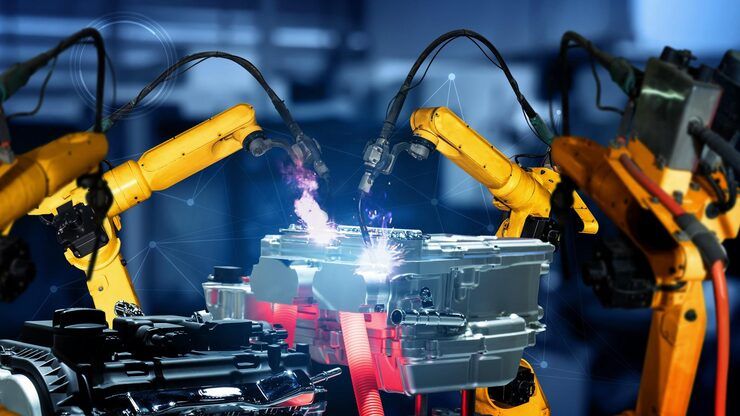

In the early days of automotive manufacturing, welding was performed manually by skilled workers using handheld tools. While effective, manual welding had limitations. Results varied depending on operator skill, fatigue, and working conditions. As vehicle designs became more complex and production volumes increased, manufacturers needed more consistent and scalable solutions.

Automotive welding robots were introduced to meet these needs. By using programmed movements, controlled welding parameters, and repeatable paths, robots ensure uniform weld quality across thousands of vehicles. Over time, they became a core part of modern automotive assembly lines, supporting mass production while maintaining quality and safety standards.

Importance – Why Automotive Welding Robots Matter Today

Automotive welding robots play a critical role in modern vehicle manufacturing by improving accuracy, efficiency, and safety.

Improves Welding Consistency

Robots perform the same weld repeatedly with controlled force, speed, and positioning.

Enhances Production Accuracy

Precise welding helps maintain correct alignment of vehicle components.

Increases Manufacturing Efficiency

Robots operate continuously with minimal downtime, supporting high-volume production.

Improves Worker Safety

Automation reduces human exposure to heat, sparks, fumes, and repetitive strain.

Supports Complex Vehicle Designs

Robots can weld in tight or hard-to-reach areas that are difficult for manual operators.

Benefits Multiple Stakeholders

Automotive welding robots support:

-

Vehicle manufacturers

-

Production and quality engineers

-

Assembly line operators

-

Workplace safety teams

Solves Common Manufacturing Challenges

Robotic welding helps address:

-

Inconsistent weld quality

-

High rework and scrap rates

-

Production bottlenecks

-

Worker injury risks

-

Difficulty scaling production

As quality expectations and production demands rise, robotic welding has become essential.

Recent Updates – Trends and Developments in 2024–2025

Automotive welding robot technology has continued to evolve over the past year, driven by digital manufacturing and efficiency goals.

Increased Use of Collaborative Robots (2024)

Some manufacturers introduced collaborative welding robots designed to work safely alongside human operators.

Improved Sensor and Vision Systems

Robots began using advanced sensors to adjust welding paths based on part positioning.

Integration with Smart Manufacturing Systems

Welding robots were increasingly connected to manufacturing execution systems for data tracking.

Energy-Efficient Welding Techniques

Manufacturers adopted optimized welding programs to reduce energy consumption.

Support for Lightweight Materials

Robots were adapted to weld aluminum and mixed materials used in modern vehicle designs.

Predictive Maintenance Capabilities

Real-time monitoring helped identify wear or faults before failures occurred.

These trends show a move toward smarter, more flexible, and data-driven welding operations.

Laws or Policies – Regulations Affecting Automotive Welding Robots

Automotive welding robots operate within regulatory frameworks focused on safety, quality, and environmental responsibility.

Workplace Safety Regulations

Robotic welding cells must include safety barriers, sensors, and emergency systems.

Machinery and Electrical Safety Standards

Robots must comply with standards governing electrical systems and mechanical motion.

Quality and Manufacturing Standards

Many manufacturers follow ISO-based quality systems that require controlled welding processes.

Environmental and Emission Regulations

Welding fumes and energy usage must be managed according to environmental guidelines.

Government Manufacturing Incentives

Some countries offer support programs encouraging automation and advanced manufacturing.

Compliance ensures safe operation and consistent product quality.

Tools and Resources – Helpful Support for Automotive Welding Robotics

Several tools and resources help manufacturers plan, operate, and maintain automotive welding robots.

Useful Tools and Resources

| Tool / Resource | Purpose / Benefit |

|---|---|

| Robotic Welding Systems | Perform automated welding tasks |

| Welding Power Controllers | Regulate current and voltage |

| Vision and Sensor Systems | Improve positioning accuracy |

| Robot Programming Software | Define welding paths and parameters |

| Simulation and Offline Programming Tools | Test processes before production |

| Preventive Maintenance Schedules | Reduce unexpected downtime |

| Safety Monitoring Systems | Protect operators |

| Production Data Dashboards | Track weld quality and efficiency |

These tools help ensure reliable and consistent robotic welding performance.

FAQs – Clear and Factual Answers

What is an automotive welding robot?

It is an automated machine used to perform welding tasks in vehicle manufacturing.

Why are welding robots used instead of manual welding?

They provide consistent quality, higher efficiency, and improved safety.

Are automotive welding robots only used in large factories?

They are most common in large plants but are also used in medium-scale operations.

Can welding robots handle different vehicle models?

Many systems are programmable and adaptable to multiple designs.

Do welding robots replace human workers completely?

No. Workers are still needed for programming, monitoring, and maintenance.

Final Thoughts

Automotive welding robots are a fundamental part of modern vehicle manufacturing. By delivering consistent weld quality, improving safety, and supporting high production volumes, they help manufacturers meet today’s demanding standards. Recent advancements in sensors, connectivity, and flexible automation have further expanded their capabilities. When implemented responsibly and in compliance with regulations, automotive welding robots contribute to reliable production, safer workplaces, and long-term manufacturing efficiency.