A Complete Guide to Gas Turbine Manufacturers: Facts, Insights, and Trends

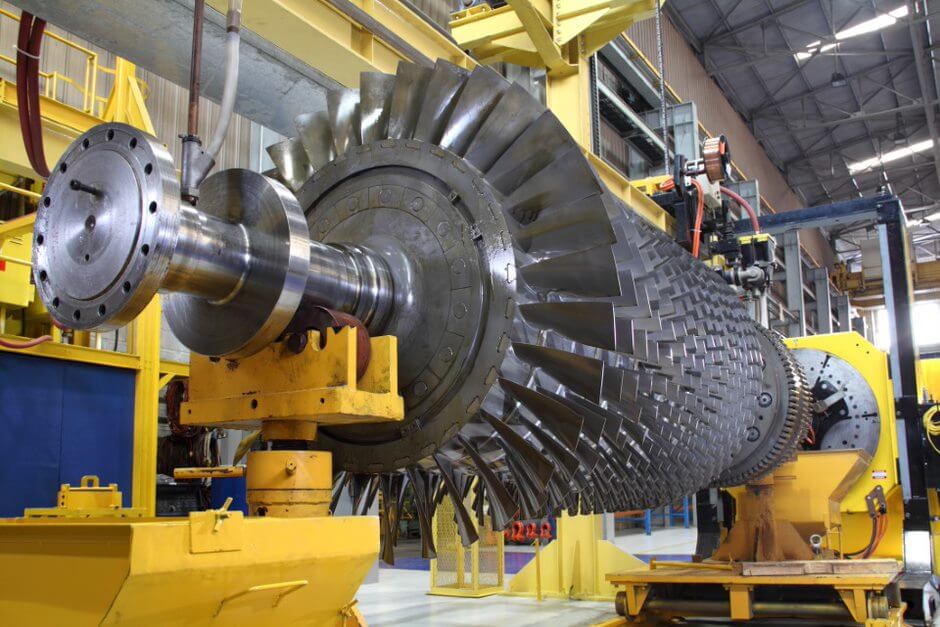

Gas turbines are rotary engines that extract energy from the flow of combustion gases. They are widely used in power generation, aviation, marine propulsion, and industrial processes. A gas turbine works on the principle of the Brayton cycle air is compressed, mixed with fuel, and ignited. The resulting high-temperature gas expands through a turbine to produce mechanical energy or electricity.

Gas turbine technology plays a vital role in modern energy infrastructure and global transportation. Manufacturers of gas turbines are responsible for designing, producing, and maintaining these complex machines, often customized for specific industries and operational environments.

Why Gas Turbines and Their Manufacturers Are Important Today

Supporting Global Energy Needs

With rising global demand for electricity and the need for flexible, quick-start power solutions, gas turbines are essential components of power grids, particularly in regions with inconsistent renewable energy sources.

Industrial and Military Applications

Gas turbines are used in:

-

Aerospace: Jet engines for commercial and military aircraft

-

Oil & Gas: Mechanical drive for compressors

-

Power Plants: Base-load and peaking power generation

-

Naval Vessels: High-speed propulsion for military ships

Efficiency and Lower Emissions

Modern gas turbines can reach efficiency levels above 60% when used in combined-cycle systems. They emit less CO₂ per kWh compared to older coal-fired systems, making them a transitional solution toward decarbonization.

Recent Updates and Industry Trends

Shift Toward Hydrogen Fuel

As of 2024, several manufacturers are working on gas turbines that can run on 100% hydrogen or a hydrogen-natural gas blend. This shift is driven by global decarbonization goals and the need to phase out fossil fuels. For example:

Siemens Energy has been testing hydrogen-ready turbines with up to 75% H₂ blends.

GE Vernova has achieved commercial operations using 50% hydrogen blends in pilot projects.

Digitalization and Predictive Maintenance

Turbine manufacturers now integrate advanced analytics, AI, and IoT into their systems. Predictive maintenance reduces downtime and helps extend turbine life. Digital twins and remote diagnostics are increasingly standard features.

Increased Demand in Emerging Markets

Countries like India, Vietnam, and Brazil are investing in gas-fired generation to stabilize their grids as they transition to renewable energy. This has created opportunities for local and global manufacturers to expand operations.

Compact and Modular Turbines

There is growing demand for smaller, modular turbines (1–20 MW) for industrial users and distributed energy systems. These units are used in areas with no grid access or for specific industrial processes.

Legal, Regulatory, and Policy Frameworks

Gas turbine manufacturing and usage are heavily influenced by international and local regulations. Key considerations include:

Emission Standards

Governments enforce emission limits on nitrogen oxides (NOx), sulfur oxides (SOx), and carbon dioxide (CO₂). Manufacturers must design turbines that meet these evolving benchmarks. For instance:

The U.S. Environmental Protection Agency (EPA) regulates emissions under the Clean Air Act.

The European Union applies strict emission norms through the Industrial Emissions Directive (IED).

Trade and Export Controls

Turbines used in military or dual-use applications (e.g., naval propulsion or critical infrastructure) are often subject to export controls. Manufacturers must comply with arms regulations and trade treaties.

Incentives for Cleaner Technology

Governments are increasingly offering grants, tax credits, and other incentives for low-emission turbine technology. In 2024, several countries introduced subsidies for hydrogen-compatible systems, including:

Germany’s National Hydrogen Strategy

India’s Green Hydrogen Mission

U.S. Inflation Reduction Act incentives for clean energy equipment

Safety and Compliance Standards

Turbines must meet safety protocols set by organizations such as:

ISO (International Organization for Standardization)

ASME (American Society of Mechanical Engineers)

IEC (International Electrotechnical Commission)

Manufacturers often undergo third-party audits to ensure product safety and environmental compliance.

Tools and Resources for Buyers and Engineers

There are several tools and platforms available to support gas turbine selection, maintenance, and lifecycle management.

Manufacturer Platforms

GE Vernova MyFleet Portal – Offers real-time monitoring and maintenance data for GE turbines.

Siemens Energy ServiceNow – Digital platform for service requests and asset tracking.

Ansaldo Energia Digital Hub – Cloud-based diagnostics and performance analytics.

Technical Calculators

Brayton Cycle Efficiency Calculator – Useful for estimating thermal performance of open and combined cycles.

Gas Turbine Emissions Estimator – Provided by environmental agencies or turbine OEMs for compliance planning.

Knowledge Portals

GasTurb.net – A technical database of gas turbine models, specifications, and performance data.

International Gas Turbine Institute (IGTI) – Publishes white papers and conference proceedings.

Energy.gov Gas Turbine Research – U.S. Department of Energy’s portal for R&D and funding opportunities.

Training and Certification

ASME Online Courses – Engineering training focused on turbomachinery design and maintenance.

Turbine Academy by Mitsubishi Power – Hands-on technical training and certifications for operators and engineers.

FAQs: Gas Turbine Manufacturing and Use

Q1: What are the main types of gas turbines?

A: The three main types are:

-

Aero-derivative turbines (used in aviation and mobile power units)

-

Heavy-duty industrial turbines (used in power plants)

-

Microturbines (used for small-scale distributed energy systems)

Each serves different purposes depending on energy needs and site conditions.

Q2: How long does a gas turbine last?

A: A typical industrial gas turbine lasts 25 to 30 years, depending on operating conditions and maintenance. Aero-derivative turbines may have shorter lifespans but are easier to refurbish.

Q3: Can gas turbines run on renewable fuels?

A: Yes. Many turbines today can operate on biofuels or hydrogen blends. However, using 100% hydrogen requires special design considerations to address flame stability and heat transfer.

Q4: Who are the top gas turbine manufacturers?

A: Leading global manufacturers include:

-

GE Vernova (USA)

-

Siemens Energy (Germany)

-

Mitsubishi Power (Japan)

-

Ansaldo Energia (Italy)

-

Rolls-Royce (UK)

-

BHEL (India) – Mainly for domestic power generation

These companies supply turbines for power generation, aviation, oil & gas, and defense sectors.

Q5: What factors affect the efficiency of a gas turbine?

A: Key factors include:

-

Turbine inlet temperature

-

Pressure ratio of the compressor

-

Ambient temperature and humidity

-

Fuel type

-

Turbine design (open vs. combined cycle)

Modern combined-cycle plants can reach efficiencies of over 60%.

Summary and Takeaway

Gas turbines continue to be a cornerstone of global power and propulsion systems. As the world moves toward cleaner energy, manufacturers are investing in hydrogen-compatible designs, digitalization, and modular solutions to meet diverse needs.

While traditional applications in aerospace and large-scale power generation remain strong, new opportunities are emerging in distributed energy, remote industrial applications, and hybrid renewable systems.

If you're involved in energy planning, engineering, or industrial operations, understanding the landscape of gas turbine manufacturing from technologies and trends to regulations and tools is essential for informed decision-making.