Your Complete Guide to Industrial Lamination Processes and Materials

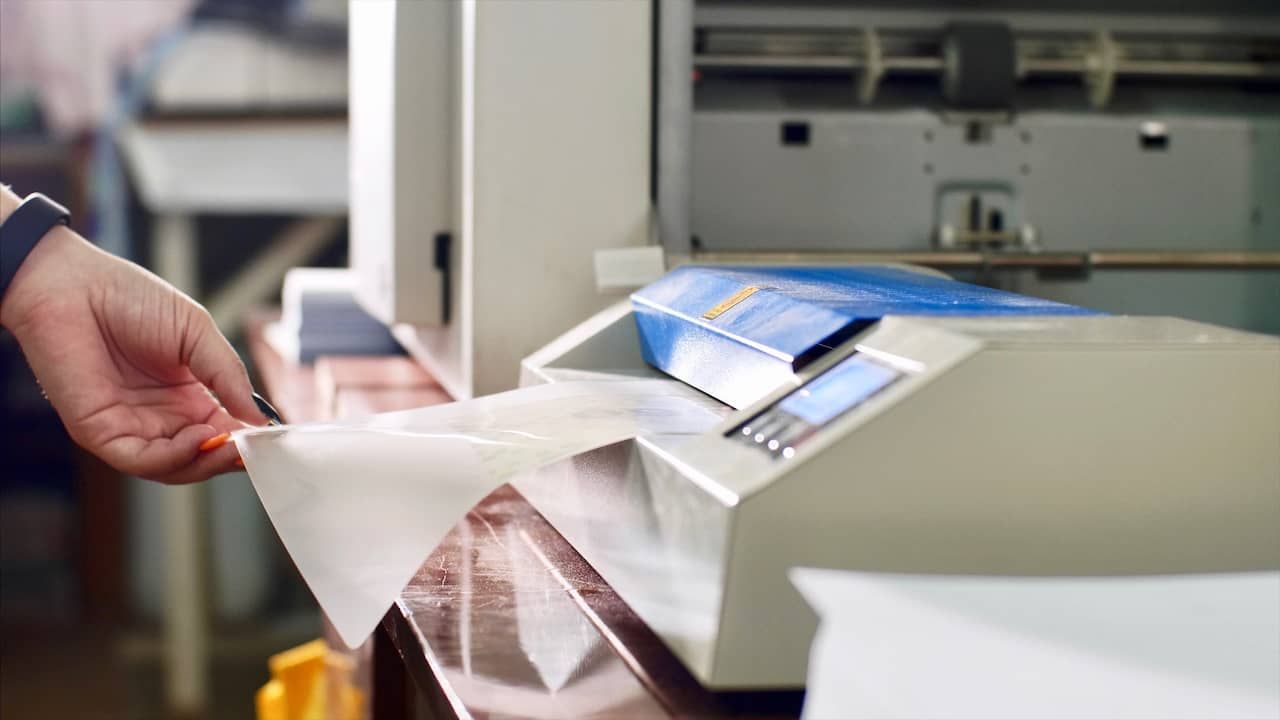

Industrial lamination is a process used to bond two or more materials together to improve their strength, durability, and appearance. It is a key operation in industries such as packaging, automotive, textiles, construction, and electronics. The process involves applying adhesives, heat, or pressure to create a layered composite material that performs better than its individual components.

Lamination was initially developed to protect printed materials like photographs and documents. Over time, it evolved into a sophisticated industrial process used for barrier protection, waterproofing, insulation, and aesthetics. Today, laminated materials are integral to products ranging from food packaging films and solar panels to automotive interiors and electronic devices.

Importance

Industrial lamination is vital because it enhances both functionality and performance in modern manufacturing. The benefits extend across multiple industries:

-

Packaging Industry: Lamination provides barrier protection against moisture, oxygen, and contaminants, increasing product shelf life.

-

Construction and Architecture: Laminated glass and boards offer safety, durability, and insulation benefits.

-

Textile and Apparel: Laminated fabrics are used in waterproof clothing, footwear, and protective gear.

-

Automotive and Aerospace: Laminated composites reduce weight and improve resistance to heat and chemicals.

-

Electronics: Lamination protects circuits and enhances thermal management in components.

From a business standpoint, lamination helps companies reduce waste, enhance sustainability, and meet safety standards. As industries increasingly move toward eco-friendly production, laminated materials are becoming more recyclable and energy-efficient.

Recent Updates

The industrial lamination sector has seen several advancements in recent years, driven by sustainability goals and technological innovation.

| Trend / Update | Details | Year / Impact |

|---|---|---|

| Eco-friendly Laminates | Introduction of recyclable and biodegradable lamination films in packaging. | 2024–2025 |

| Digital Lamination Machines | Integration of automation and digital control for higher precision. | 2024 |

| High-performance Adhesives | Development of solvent-free and low-VOC adhesives. | 2023–2024 |

| Multi-layer Film Innovation | Use of nano-coated and multi-functional barrier films for enhanced protection. | 2024 |

| Renewable Materials | Growing use of bio-based resins and plant-derived polymers in lamination. | 2025 |

The global industrial lamination market is expected to continue growing, supported by increased demand from packaging, renewable energy, and construction industries.

Laws or Policies

Lamination processes are subject to several environmental and manufacturing regulations to ensure worker safety, product quality, and environmental compliance.

Environmental Regulations:

-

VOC Emission Standards: Many countries limit the use of solvent-based adhesives to reduce volatile organic compound emissions.

-

Waste Management Policies: Manufacturers must handle laminated waste responsibly to prevent microplastic pollution.

-

Eco-Design Directives: In the European Union, product designs must allow recyclability and reuse of laminated materials.

Safety and Industry Standards:

-

ISO 9001: Ensures quality management in lamination processes.

-

ISO 14001: Covers environmental management practices for lamination manufacturers.

-

REACH (EU): Regulates the use of chemical substances in adhesives and coatings.

-

OSHA Guidelines (U.S.): Focus on worker safety during lamination, especially where heat and chemicals are involved.

Packaging Regulations:

Countries like India, Egypt, and Saudi Arabia have introduced policies to encourage recyclable laminates in food packaging by 2024, aligning with global sustainability targets.

Tools and Resources

Several digital tools, machines, and online platforms assist in optimizing lamination processes.

Industrial Equipment and Systems

| Machine Type | Function |

|---|---|

| Dry Lamination Machine | Uses heat and pressure to bond films using solvent-based adhesives. |

| Wet Lamination Machine | Employs liquid adhesive for film-to-paper or film-to-foil bonding. |

| Extrusion Lamination System | Combines molten polymer layers with substrates for strong adhesion. |

| Thermal Lamination Equipment | Ideal for packaging and label industries. |

| Roll-to-Roll Lamination Machines | Used in flexible packaging and electronic film production. |

Software and Digital Tools

-

Autodesk Fusion 360: Designs and simulates laminated structures.

-

MATLAB Material Toolbox: Analyzes layer properties and bonding strength.

-

Adhesive Selector by Henkel: Helps choose the right adhesive for various lamination materials.

-

Comsol Multiphysics: Models lamination heat transfer and stress distribution.

Web Resources

-

Packaging Europe: www.packagingeurope.com

-

European Coatings: www.european-coatings.com

-

Polymer Update: www.polymerupdate.com

These tools enable engineers, material scientists, and manufacturers to improve product quality while reducing waste and costs.

FAQs

1. What is the main purpose of industrial lamination?

The main purpose is to combine materials to enhance durability, protection, and performance for applications like packaging, electronics, and construction.

2. What are the types of lamination processes?

Common types include dry lamination, wet lamination, extrusion lamination, and thermal lamination, each suited for different materials and industrial uses.

3. Which materials are commonly laminated?

Materials such as paper, plastic films, aluminum foil, textiles, and glass are often laminated to create composite materials with enhanced properties.

4. Is industrial lamination environmentally friendly?

It depends on the materials used. New technologies and biodegradable laminates are making the process more sustainable and recyclable.

5. What industries benefit most from lamination?

Major industries include food and beverage packaging, construction, textiles, automotive, and renewable energy.

Table: Common Lamination Materials and Their Applications

| Material | Common Application | Benefits |

|---|---|---|

| PET Film | Food packaging, labels | Strength, transparency, chemical resistance |

| BOPP Film | Snack packaging, books | Gloss, lightweight, printable surface |

| Aluminum Foil | Pharma, insulation | Barrier protection, heat resistance |

| Laminated Glass | Buildings, vehicles | Safety, UV resistance |

| Fabric Laminate | Outdoor gear, uniforms | Waterproofing, durability |

Graph: Industrial Lamination Usage by Sector (2024 Estimate)

| Sector | Market Share (%) |

|---|---|

| Packaging | 45% |

| Construction | 25% |

| Automotive & Aerospace | 15% |

| Electronics | 10% |

| Others | 5% |

Final Thoughts

Industrial lamination has become a cornerstone of modern manufacturing, combining materials for superior performance and longevity. As industries prioritize sustainability, recyclability, and digital precision, the future of lamination lies in eco-friendly materials and automation-driven processes.

Understanding the right combination of materials, technologies, and legal standards enables industries to enhance efficiency while minimizing environmental impact. Whether in packaging or construction, lamination continues to be a silent but powerful contributor to industrial progress.