Understanding Board Mount Power Supply Accessories: Key Insights, Technical Details

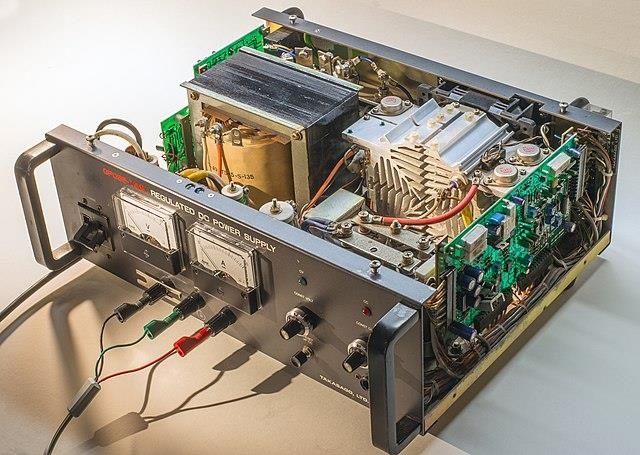

Board mount power supply accessories refer to the supporting components used alongside board-level power modules or converters that are physically mounted on printed circuit boards (PCBs). These accessories play an important role in how power is delivered, filtered, protected, and stabilized inside electronic devices.

Most modern electronics including embedded systems, automation devices, IoT hardware, robotics modules, telecom equipment, medical instruments, and industrial controllers depend on compact, efficient power supplies. Board mount power supplies are chosen for their small size, ease of integration, and reliable performance.

However, these small modules often require additional accessories to enhance electrical safety, electromagnetic compatibility, stability, and thermal management. The purpose of these accessories is not only to support power conversion but also to ensure the overall system performs consistently under different load and environmental conditions.

Common board mount power supply accessories include:

-

EMI filters

-

Input/output connectors

-

Heat sinks

-

Mounting hardware

-

Fuses and protection components

-

Capacitors and inductors for filtering

-

Isolation barriers

-

Solder-in pins and adapters

These accessories exist to help engineers manage noise, reduce overheating, prevent failures, and extend the reliability of electronic products.

Importance

Board mount power supply accessories are essential because they directly influence the performance and longevity of electronic systems. They matter today for several key reasons:

Rising Miniaturization

As devices become smaller, PCB real estate becomes limited. Accessories that enhance electrical integrity without increasing footprint are more important than ever.

Growing Power Density

Power supplies today handle more energy in compact packages. Effective thermal accessories like small heat sinks and airflow components help improve efficiency and prevent damage from heat buildup.

EMI and Noise Control

Many industries — telecom, computing, medical, automotive, and aerospace — demand strict electromagnetic interference (EMI) control. Accessories such as EMI shields, metal covers, and filtering capacitors help maintain signal quality and compliance.

Safety and Protection

Accessories like fuses, TVS diodes, and isolation components safeguard sensitive circuits against:

-

Overvoltage

-

Short circuits

-

Load fluctuations

-

Static discharge

This prevents failures and reduces downtime in mission-critical applications.

Reliability in Harsh Conditions

Industrial and outdoor electronics face temperature swings, vibration, humidity, and dust. Accessories such as coating materials, thermal pads, and enclosure-compatible hardware help ensure stable performance.

Who It Affects

Board mount power supply accessories impact:

-

Electronics engineers and designers

-

PCB manufacturers

-

Embedded system developers

-

Industrial automation teams

-

Research and prototyping groups

-

IoT hardware designers

These individuals rely on accessories to improve the integration, safety, and stability of board-level power solutions.

Recent Updates

The last year has seen noticeable updates in board mount power supply accessories, driven by efficiency requirements, safety standards, and design innovations. Some key developments include:

2024–2025 Trends

-

High-efficiency filtering components (2024): New multilayer ceramic capacitors and mini inductors offer improved noise reduction in smaller footprints.

-

GaN and SiC power supply compatibility (2024–2025): Accessories such as high-voltage isolation barriers and heat spreaders are optimized for GaN/SiC-based power modules.

-

Enhanced thermal interface materials (2025): Manufacturers introduced ultra-thin graphite thermal sheets for heat dissipation in compact PCBs.

-

Low-EMI connector designs (2024): Specialized connectors with integrated shielding became popular for telecom and networking boards.

-

Environmentally conscious materials (2024–2025): Accessories now increasingly follow RoHS, WEEE, and lead-free manufacturing standards.

Industry Movement Toward Higher Power Density

Electronics trends in 2024–2025 show a shift toward higher-density board mount converters. This pushed accessory manufacturers to develop compact heat sinks, snap-on shields, and modular fuse carriers.

Updates in Quality Standards

-

New IEC amendments in late 2024 improved guidelines on creepage and clearance distances for board mount applications.

-

IPC committees announced updated recommendations for power integrity testing in 2025.

These shifts indicate that power supply accessories are evolving to handle more energy, more complexity, and stricter regulations.

Laws or Policies

Regulations influence how board mount power supply accessories are designed, manufactured, and used. While specifics vary by country, some widely recognized standards apply across major markets.

Electrical Safety Standards

-

IEC 62368-1: Governs safety of audio/video, ICT, and telecom equipment. Accessories must support safe temperatures, insulation, and fire resistance.

-

UL Safety Ratings: Many accessories such as fuses, connectors, and isolation components must comply with UL standards.

EMI/EMC Compliance

-

CISPR 32 and CISPR 35: Define electromagnetic emission and immunity requirements.

-

FCC Part 15 (USA): Restricts electromagnetic interference from electronic devices.

Accessory designers must ensure filters and shield components meet these requirements.

Environmental Regulations

-

RoHS (Restriction of Hazardous Substances): Limits lead, mercury, cadmium, and other restricted substances in electrical accessories.

-

REACH Compliance (EU): Ensures materials follow chemical safety requirements.

Quality and Manufacturing Standards

-

IPC-2221 and IPC-9592B: Provide guidelines for power conversion components, thermal design, and board reliability.

-

ISO 9001 (Manufacturing Quality): Ensures consistency in accessory production processes.

These regulations ensure that board mount power supply accessories are safe, reliable, environmentally friendly, and compatible with modern electronic systems.

Tools and Resources

Below are helpful tools, calculators, and references frequently used when selecting or designing board mount power supply accessories.

Design and Simulation Tools

-

LTspice – Circuit simulation software for testing filtering components and protection circuits.

-

KiCad / Altium Designer – PCB design tools used to plan mounting hardware, connectors, and placement for power accessories.

-

Thermal Simulation Tools (e.g., SimScale, Ansys Icepak) – Useful for calculating heat dissipation and selecting suitable heat sinks or thermal pads.

Calculators

-

Power Loss Calculator – Estimates power dissipation in components and helps choose thermal accessories.

-

EMI Filter Calculator – Assists in selecting correct capacitors and inductors for noise control.

-

Current Rating Calculator – Useful when choosing connectors and fuse accessories.

Datasheet Libraries

-

Digikey and Mouser component catalogs – Provide datasheets, footprints, compliance details, and technical specifications.

-

IEC and UL Standard Databases – For verifying compliance and regulatory needs.

Documentation Templates

-

PCB layout templates – Help document proper spacing for connectors, isolation areas, and mounting holes.

-

Thermal Management Guides – Documents for selecting thermal materials and evaluating power module heat spread.

Engineering Communities

-

Stack Exchange: Electrical Engineering

-

IEEE technical papers

-

Open-source electronics forums

These resources help designers understand, test, and integrate board mount power supply accessories efficiently.

Table: Common Board Mount Power Supply Accessories and Their Functions

| Accessory Type | Main Function | Typical Use Cases |

|---|---|---|

| EMI Filters | Reduce electrical noise | Telecom, medical devices |

| Heat Sinks | Dissipate heat | High-density converters |

| Fuses/Protection | Prevent overload and failures | Industrial, automation |

| Isolation Barriers | Improve safety and signal integrity | Power modules with high voltages |

| Connectors | Reliable power input/output | Embedded and IoT devices |

| Capacitors/Inductors | Voltage smoothing and filtering | DC-DC converters |

FAQs

What are board mount power supply accessories used for?

They are used to support and enhance the function of PCB-mounted power modules by improving noise control, thermal management, and electrical protection.

Do these accessories affect performance?

Yes. Proper accessories can enhance stability, improve power quality, extend lifespan, and help meet regulatory requirements.

Are EMI filters mandatory?

They are not always mandatory, but they are often recommended when devices must comply with EMI/EMC standards such as CISPR or FCC regulations.

Can thermal accessories be replaced with software optimization?

No. While firmware can optimize power usage, physical heat dissipation must still be managed through thermal pads, sinks, or interface materials.

How do I choose the right accessories?

Selection depends on factors such as voltage, current, thermal load, space limitations, EMI requirements, and relevant safety standards.

Conclusion

Board mount power supply accessories play a critical role in ensuring that electronic systems operate safely, efficiently, and reliably. They support functions such as filtering, cooling, protection, mounting, and isolation. Their importance continues to grow as industries shift toward miniaturization, higher power density, and stricter regulatory requirements.

Recent developments in materials, EMI shielding, thermal technologies, and compliance standards highlight the evolving nature of board-level power design. By using appropriate tools, simulations, and datasheet resources, designers can select the right accessories to enhance electrical performance and long-term durability.

This educational overview provides a clear understanding of how these accessories function, why they matter, and how they fit into today’s electronics landscape.