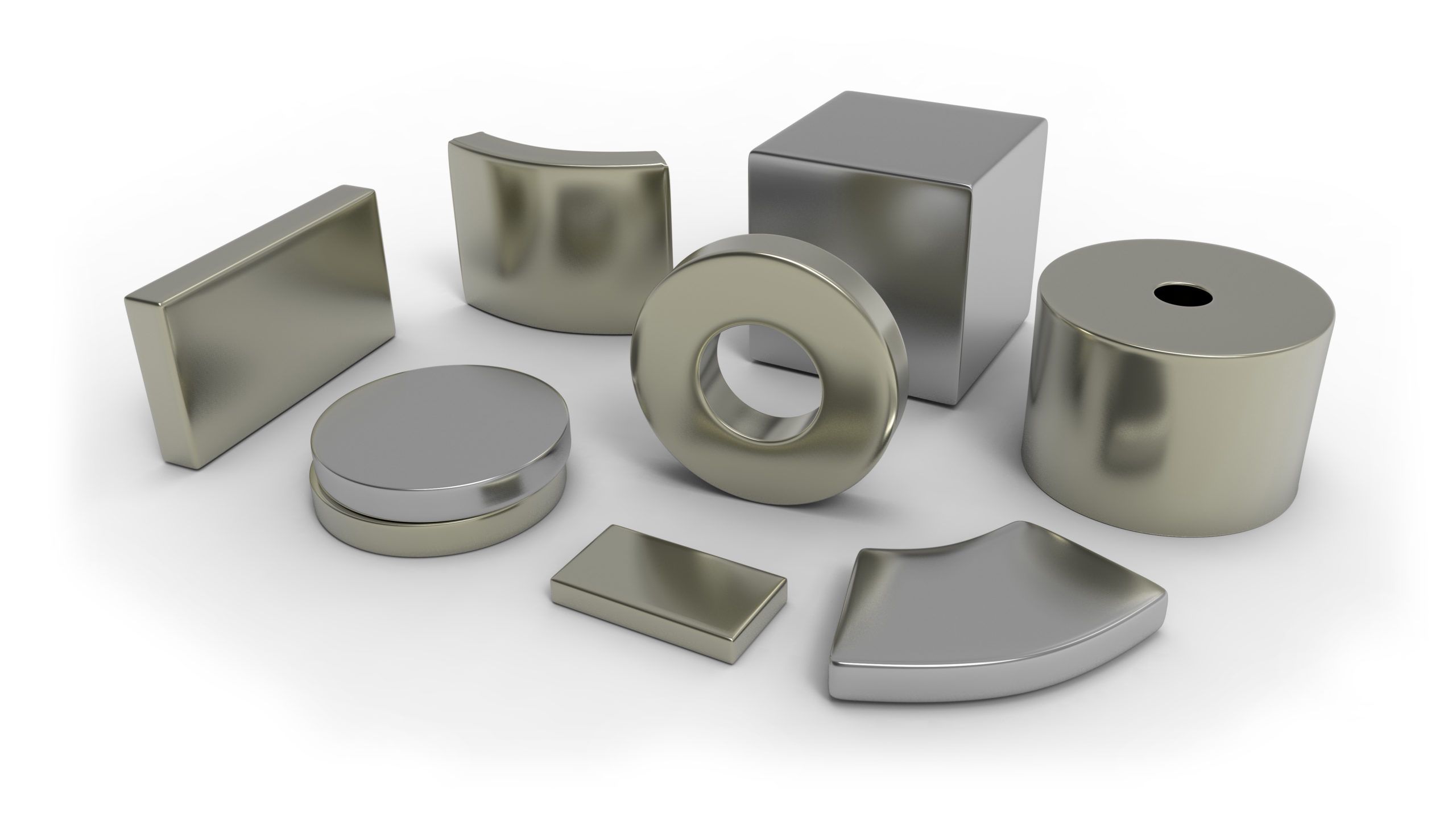

Sensor Matched Magnets: An Expert Guide with Key Insights and Useful Information

Sensor matched magnets are specially calibrated magnetic components designed to work in precise alignment with magnetic sensors. They ensure accurate readings, stable output, and consistent performance in applications such as robotics, automotive electronics, industrial automation, aerospace systems, and smart devices. The purpose of matching magnets with sensors is to achieve predictable magnetic fields that help the sensor detect position, speed, angle, or motion with high reliability.

These magnets are produced through controlled manufacturing processes where magnetic strength, polarity, and orientation are optimized for specific sensor technologies. Common sensor types that rely on matched magnets include Hall-effect sensors, AMR sensors, GMR sensors, TMR sensors, and magneto-resistive encoders. As devices become smaller and more powerful, sensor matched magnets are increasingly essential for maintaining stability and accuracy in compact environments.

Importance

Sensor matched magnets matter today because modern systems depend on precise data to operate safely and efficiently. As industries adopt automation and AI-powered control systems, accuracy in magnetic sensing directly impacts manufacturing quality, user experience, and operational safety.

Several groups benefit from this technology:

-

Engineers and designers who require consistent sensing performance.

-

Automotive manufacturers developing electric vehicles, ADAS, and steering systems.

-

Industrial automation companies building high-precision machinery.

-

Robotics developers working on motion control and navigation.

-

Medical device engineers designing monitoring and diagnostic equipment.

-

Electronics researchers exploring miniaturization and smart technologies.

Sensor matched magnets solve problems such as signal drift, measurement errors, alignment complexity, and inconsistent sensor response. By ensuring magnetic uniformity, they enhance system stability, reduce calibration effort, and support long-term reliability.

Recent Updates

During the past year, several developments have shaped the use and design of sensor matched magnets. These updates reflect changes in manufacturing, materials, and sensor integration:

-

Increased demand in EV and battery systems (2024–2025) as automakers adopt magnetic position sensors for current measurement, motor control, and pedal monitoring.

-

Advances in TMR and GMR sensor technologies (2024) have encouraged the use of magnets with more precise magnetic flux density calibration.

-

Growth of industrial robotics (2024) pushed manufacturers to focus on micro-magnets for compact, high-resolution encoders.

-

Shift toward environmentally friendly magnet materials due to global efforts to reduce rare-earth dependency.

-

AI-powered testing and simulation tools (2024) are now used to optimize magnetic fields during design, improving consistency before production.

-

Stricter quality standards in automotive electronics (2024–2025) have increased demand for matched magnet-sensor sets that meet ISO 11452 and CISPR regulations.

These trends show that sensor matched magnets are transitioning from optional to essential components in advanced electronic systems.

Laws or Policies

Sensor matched magnets are influenced by several regulations, particularly in manufacturing nations such as India, the EU, and the United States. These rules ensure product safety, electromagnetic compatibility, and environmental compliance.

Relevant policies include:

-

RoHS (Restriction of Hazardous Substances) – Limits the use of harmful materials in magnets and sensors.

-

REACH regulations – Control chemical substances used during magnet production.

-

IEC and ISO standards for sensor performance – Define calibration accuracy, electromagnetic behavior, and durability testing.

-

Automotive industry guidelines like ISO 26262 for functional safety in magnet-sensor systems used in steering, braking, and drivetrain components.

-

India’s Electronics Policy updates (2023–2024) which encourage domestic production of sensors and magnetic components under quality and safety frameworks.

-

Export and supply-chain guidelines for rare-earth materials, which influence global magnet sourcing and pricing.

These policies ensure that sensor matched magnets meet strict criteria for performance, environmental safety, and long-term reliability.

Tools and Resources

Several tools and resources can help engineers, students, and researchers working with sensor matched magnets. These options support design, testing, simulation, and performance evaluation.

Simulation and Modeling Tools

-

Magneto-static simulation software such as FEMM for analyzing magnetic fields.

-

COMSOL Multiphysics for advanced electromagnetic modeling.

-

Ansys Maxwell for simulating magnet-sensor interactions.

Design and Alignment Tools

-

Magnetic field calculators for flux density estimation.

-

Sensor alignment jigs used in prototyping and testing stages.

-

3D CAD tools like SolidWorks and Fusion 360 with magnetism plugins.

Testing and Measurement Tools

-

Gaussmeters for checking flux density and magnet uniformity.

-

Helmholtz coil systems for controlled magnetic field testing.

-

Precision rotary stages for angle sensor evaluation.

Online Resources and Reference Databases

-

IEEE Xplore Library for research papers on magnetic sensing.

-

Engineering knowledge platforms offering magnet-sensor design guidelines.

-

Material property databases listing magnet grades and specifications.

These tools help ensure accurate design, safer integration, and improved performance of sensor matched magnets in multiple applications.

Comparison Table: Sensor Types vs. Magnet Requirements

| Sensor Technology | Typical Applications | Magnet Requirements |

|---|---|---|

| Hall-Effect Sensor | Automotive controls, switches | Moderate flux density, stable orientation |

| AMR Sensor | Robotics, industrial automation | High linearity, low hysteresis |

| GMR Sensor | Precision motion control | Strong, uniform magnetic field |

| TMR Sensor | High-resolution encoders | Very stable flux, precise matching |

| Magneto-resistive Encoder | Position and angle sensing | Consistent field symmetry |

FAQs

1. What are sensor matched magnets?

Sensor matched magnets are magnets calibrated to work specifically with certain sensors to ensure accurate and consistent measurements. They provide stable magnetic fields that help sensors detect position, rotation, or speed with high precision.

2. Why are matched magnets better than standard magnets?

Standard magnets can vary in strength or orientation. Matched magnets undergo controlled manufacturing and calibration to meet strict performance requirements, making them more reliable for precision systems such as robotics, industrial automation, and automotive electronics.

3. Which industries use sensor matched magnets most frequently?

They are widely used in automotive electronics, electric vehicles, robotics, aerospace, industrial automation, renewable energy equipment, and consumer electronics requiring accurate motion sensing.

4. Do sensor matched magnets require special installation?

Yes. Proper alignment and spacing between the magnet and sensor are essential. Many manufacturers recommend specific mounting distances and orientations to maintain measurement accuracy.

5. What materials are commonly used for sensor matched magnets?

Neodymium (NdFeB), ferrite, samarium-cobalt, and specialized alloys depending on temperature stability requirements and magnetic performance needs.

Conclusion

Sensor matched magnets are an essential part of today’s advanced sensing technologies. As industries depend more on automation, robotics, AI-powered control systems, and high-precision electronics, the role of accurately calibrated magnets becomes increasingly important. Their ability to provide stable, predictable magnetic fields supports safer designs, improved efficiency, and reliable performance across multiple sectors.

Ongoing advancements in sensor technology, material science, and manufacturing processes continue to improve the quality and capabilities of matched magnets. With the support of new tools, updated regulations, and global research, they are becoming a central component in next-generation electronic systems.