SCADA systems exist to help operators understand what is happening in complex systems without being physically present at every site. In large facilities, utilities, or infrastructure networks, it is not practical to manually check each machine or process. SCADA systems solve this challenge by gathering real-time data and allowing remote supervision.

The concept emerged alongside industrial automation and the expansion of large-scale infrastructure such as power grids, water distribution networks, and manufacturing plants. As systems grew more complex, there was a need for centralized oversight, faster response to issues, and better data-driven decision-making.

Today, SCADA control systems are a foundational part of modern industrial environments. They act as the bridge between physical operations and digital monitoring, enabling consistent and reliable control across wide geographic areas.

Why SCADA Control Systems Matter Today

SCADA control systems play a critical role in how essential services and industries operate. They affect a wide range of sectors, including energy, water management, manufacturing, transportation, and oil and gas.

This topic matters today because industries are becoming more automated, interconnected, and data-driven. Operators need accurate, real-time information to maintain stability, efficiency, and safety. SCADA systems help solve several modern challenges:

-

Monitoring complex processes continuously

-

Detecting faults or irregular behavior early

-

Reducing downtime through faster response

-

Improving operational transparency

| Operational Need | How SCADA Helps |

|---|---|

| Real-time visibility | Live data dashboards |

| Process stability | Automated alerts |

| Operational efficiency | Centralized control |

| Risk reduction | Early fault detection |

SCADA systems are especially important in critical infrastructure where failures can affect large populations. By enabling remote supervision, they reduce reliance on manual checks and improve response times during emergencies.

Core Components and How SCADA Systems Work

A SCADA control system is made up of several interconnected components that work together to collect data, process it, and present it to human operators.

Key components include:

-

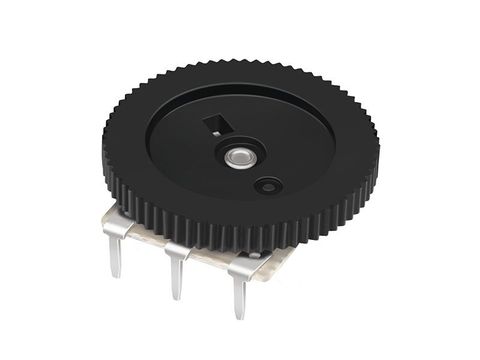

Sensors and field devices

-

Programmable controllers

-

Communication networks

-

Central SCADA software

-

Human-machine interfaces (HMIs)

Sensors and field devices collect data such as temperature, pressure, flow rate, or electrical current. Controllers process this information locally and send it through communication networks to a central system. The SCADA software then displays the data on visual screens, allowing operators to monitor conditions and make adjustments when needed.

| Component | Purpose |

|---|---|

| Sensors | Measure physical values |

| Controllers | Execute control logic |

| Networks | Transmit data |

| SCADA software | Analyze and display data |

| HMI | Operator interaction |

This layered structure allows SCADA systems to scale from small facilities to nationwide networks.

Common Applications Across Industries

SCADA control systems are used wherever processes need to be monitored and controlled reliably over time and distance.

Typical applications include:

-

Power generation and transmission

-

Water treatment and distribution

-

Manufacturing process control

-

Transportation signaling systems

-

Oil and gas pipeline monitoring

| Industry | SCADA Use Case |

|---|---|

| Energy | Grid monitoring |

| Water | Pump and reservoir control |

| Manufacturing | Process automation |

| Transport | Signal supervision |

| Utilities | Network performance tracking |

These systems support continuous operation and help maintain consistent quality and safety standards.

Recent Updates and Trends in 2024–2025

Over the past year, SCADA control systems have continued to evolve in response to digital transformation and cybersecurity concerns.

Notable developments include:

-

Early 2024: Increased integration with cloud-based data platforms

-

Mid 2024: Greater focus on cybersecurity monitoring

-

Late 2024: Expansion of remote access and mobile visualization

-

Early 2025: Adoption of data analytics for predictive insights

| Period | Update | Impact |

|---|---|---|

| 2024 | Cloud integration | Improved data access |

| 2024 | Cybersecurity focus | Reduced risk exposure |

| 2024 | Remote visualization | Better flexibility |

| 2025 | Advanced analytics | Improved forecasting |

These trends reflect the growing importance of secure, connected, and intelligent control systems.

Laws, Regulations, and Policy Considerations

SCADA control systems are closely linked to safety, reliability, and national infrastructure, so they are influenced by various laws and regulations. These policies aim to ensure that systems operate securely and responsibly.

Regulatory considerations often include:

-

Industrial safety standards

-

Data protection and cybersecurity guidelines

-

Environmental monitoring requirements

-

Critical infrastructure protection policies

Government programs supporting smart infrastructure and digital utilities also encourage the modernization of SCADA systems. Compliance with regulations helps reduce operational risks and supports public safety.

Tools and Resources for Learning and Managing SCADA Systems

Several tools and resources help users understand, design, and manage SCADA control systems effectively.

Helpful resources include:

-

System architecture reference guides

-

Network design diagrams

-

Data logging and visualization tools

-

Cybersecurity assessment frameworks

-

Maintenance and monitoring templates

| Resource Type | Practical Use |

|---|---|

| Architecture guides | System planning |

| Diagrams | Network understanding |

| Visualization tools | Data interpretation |

| Security frameworks | Risk assessment |

| Templates | Operational consistency |

These resources support informed decision-making and reliable system operation.

Frequently Asked Questions

What does a SCADA control system do?

It monitors and controls industrial processes by collecting data from field devices and presenting it to operators.

Is SCADA used only in large industries?

No, SCADA systems can be scaled for small facilities as well as large networks.

How does SCADA improve safety?

By providing real-time alerts and reducing the need for manual intervention in hazardous areas.

Can SCADA systems operate remotely?

Yes, remote monitoring is a core feature of modern SCADA systems.

Are SCADA systems part of automation?

Yes, they are a key component of industrial automation and control.

Conclusion

SCADA control systems are essential for managing complex industrial and infrastructure processes in a reliable and efficient way. By combining data collection, visualization, and control, they enable operators to maintain stability, respond quickly to issues, and make informed decisions.

As industries continue to adopt digital technologies, SCADA systems are evolving with stronger connectivity, improved security, and smarter analytics. Supported by regulations, practical tools, and ongoing innovation, SCADA control systems remain a cornerstone of modern industrial operations.