Metal Forming Machinery Guide: Explore Basics, Processes, and Key Insights

Metal forming machinery refers to equipment used to shape metal materials into desired forms by applying controlled force. These machines exist to transform raw metal into components used across construction, transportation, manufacturing, and infrastructure. Instead of removing material, metal forming changes the shape of metal while preserving its mass, making it an efficient and widely used manufacturing approach.

Metal forming machinery plays a central role in modern industry. From simple brackets to complex structural components, many everyday products rely on metal forming processes. Understanding how these machines work and why they matter provides insight into how industrial systems produce strong, reliable, and standardized metal parts.

Context

Metal forming is one of the oldest manufacturing practices. Early civilizations shaped metals using hammers, anvils, and basic molds to create tools, weapons, and ornaments. These manual techniques relied heavily on human strength and skill and were limited in scale and consistency.

With the industrial revolution, mechanical power replaced manual force. Presses, rollers, and forming machines allowed metals to be shaped more precisely and in larger quantities. Over time, advancements in materials science and mechanical engineering led to specialized metal forming machinery designed for different metals, thicknesses, and shapes.

Metal forming machinery exists to:

-

Shape metal efficiently without excessive waste

-

Produce consistent parts at scale

-

Improve strength through controlled deformation

-

Support diverse industrial applications

Today, metal forming machinery is essential in both heavy industry and precision manufacturing.

Importance

Metal forming machinery matters because it enables the production of structural and functional components used worldwide.

Why metal forming machinery is important:

-

Efficient material use

Shapes metal without significant material loss. -

High structural strength

Forming processes often improve metal properties. -

Scalable production

Supports mass production with uniform quality. -

Versatile applications

Used in construction, automotive, aerospace, and appliances. -

Reduced secondary processing

Produces near-finished shapes in fewer steps.

Who this topic affects:

-

Manufacturing and mechanical engineers

-

Industrial technicians and operators

-

Engineering students and educators

-

Infrastructure and construction planners

-

Quality and safety regulators

Problems metal forming machinery helps solve:

-

Inefficiency of cutting-based methods

-

Inconsistent part dimensions

-

High material waste

-

Difficulty shaping high-strength metals

Metal forming machinery supports modern production needs with efficiency and reliability.

Basic Principles of Metal Forming

Metal forming works by applying stress to a metal workpiece until it permanently deforms without cracking.

Key principles include:

-

Plastic deformation of metals

-

Controlled application of force

-

Use of dies, rollers, or molds

-

Balance between strength and ductility

The success of metal forming depends on material properties, temperature, and forming speed.

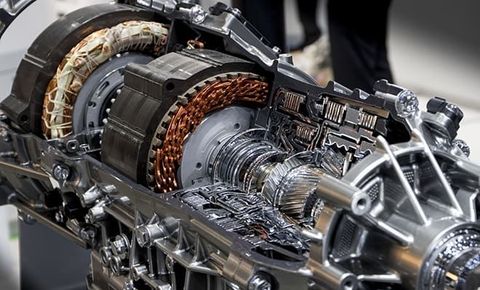

Common Types of Metal Forming Machinery

Different machines are designed for specific forming operations.

Press Machines

Use mechanical or hydraulic force to shape metal.

-

Suitable for stamping and punching

-

Common in sheet metal forming

Rolling Mills

Pass metal between rollers to reduce thickness or shape profiles.

-

Used for sheets, plates, and structural sections

-

Continuous and efficient process

Forging Machines

Apply compressive force to shape heated or cold metal.

-

Improve strength and grain structure

-

Used for high-load components

Bending Machines

Deform metal along a straight axis.

-

Used for angles, channels, and frames

-

Common in fabrication workshops

Extrusion Machines

Force metal through a die to create continuous profiles.

-

Used for rods, tubes, and complex shapes

Metal Forming Machinery Comparison Table

| Machine Type | Primary Process | Typical Output | Key Characteristic |

|---|---|---|---|

| Press Machine | Stamping | Sheet components | High precision |

| Rolling Mill | Rolling | Plates and sheets | Continuous shaping |

| Forging Machine | Forging | Structural parts | Strength enhancement |

| Bending Machine | Bending | Angled sections | Shape accuracy |

| Extrusion Machine | Extrusion | Uniform profiles | Complex cross-sections |

This table shows how different machines support specific forming needs.

Metal Forming Processes Explained

Metal forming machinery supports various forming processes.

Hot Forming

-

Metal heated above recrystallization temperature

-

Lower forming force required

-

Used for large or complex shapes

Cold Forming

-

Performed at or near room temperature

-

Improved surface finish and strength

-

Requires higher force

Sheet Metal Forming

-

Involves bending, drawing, or stamping

-

Used for enclosures and panels

Bulk Metal Forming

-

Large deformation of metal volume

-

Includes rolling, forging, and extrusion

Each process balances energy use, material properties, and final part requirements.

Performance Factors in Metal Forming Machinery

Machine performance directly affects part quality and efficiency.

Key performance factors include:

-

Force capacity and control

-

Tooling accuracy and wear resistance

-

Speed and cycle time

-

Temperature management

-

Alignment and stability

Proper calibration ensures consistent results and reduces defects.

Material Considerations

Different metals respond differently to forming processes.

Commonly formed materials include:

-

Steel and stainless steel

-

Aluminum alloys

-

Copper and brass

-

Titanium and specialty alloys

Material selection influences machine choice and process parameters.

Safety and Operational Awareness

Metal forming machinery operates under high force and energy.

General safety considerations include:

-

Guarding of moving components

-

Emergency stop systems

-

Proper tooling installation

-

Operator training and awareness

Safe operation protects personnel and equipment integrity.

Recent Updates and Trends

During 2024–2025, metal forming machinery reflected advances in automation and efficiency:

-

Increased automation and CNC integration

Improved accuracy and repeatability. -

Energy-efficient hydraulic systems

Reduced power consumption. -

Advanced sensor monitoring

Real-time force and temperature tracking. -

Improved tooling materials

Longer tool life and reduced downtime. -

Flexible forming systems

Adaptable machines for varied part designs. -

Data-driven process optimization

Enhanced quality control through analytics.

These trends highlight the move toward smarter and more adaptable manufacturing.

Environmental and Resource Considerations

Metal forming machinery influences environmental performance.

Key considerations include:

-

Energy consumption

-

Lubricant use and disposal

-

Noise and vibration control

-

Tool and machine lifespan

Efficient machinery supports sustainable manufacturing goals.

Laws and Policies

Metal forming machinery is influenced by industrial and safety regulations.

Key regulatory areas include:

-

Workplace safety regulations

Address machine guarding and operator protection. -

Equipment standards

Define performance and safety requirements. -

Environmental compliance rules

Govern emissions, waste, and resource use. -

Manufacturing quality standards

Support consistency and traceability. -

Energy efficiency policies

Encourage reduced industrial energy use.

These frameworks promote safe and responsible machine operation.

Tools and Resources

Several non-commercial tools and references support learning about metal forming machinery:

Educational Resources

-

Manufacturing engineering textbooks

-

Metal forming process guides

Technical Tools

-

Force and deformation calculation worksheets

-

Forming process simulation diagrams

Safety References

-

Machine safety manuals

-

Industrial operation guidelines

Research Publications

-

Materials science journals

-

Manufacturing technology studies

These resources help learners understand both theory and practice.

FAQs

What is metal forming machinery used for?

It is used to shape metal into components through controlled deformation.

Is metal forming different from machining?

Yes. Forming reshapes metal, while machining removes material.

Does metal forming improve strength?

Many forming processes enhance strength through grain alignment.

Are all metals suitable for forming?

Most metals can be formed, but suitability varies by alloy and process.

Is metal forming machinery regulated?

Yes. Safety, quality, and environmental regulations apply.

Practical Learning Insights

For those studying metal forming machinery:

-

Understand material behavior under stress

-

Learn differences between hot and cold forming

-

Observe tooling design and wear effects

-

Study safety requirements alongside mechanics

-

Explore how automation improves consistency

These insights support a balanced technical foundation.

Conclusion

Metal forming machinery is a cornerstone of modern manufacturing, enabling efficient and reliable shaping of metals for countless applications. By applying controlled force rather than removing material, these machines support high-strength components, reduced waste, and scalable production. From presses and rolling mills to forging and extrusion systems, metal forming machinery reflects centuries of engineering progress.

By examining metal forming machinery through context, importance, processes, recent trends, regulatory frameworks, and educational resources, readers gain a clear and practical understanding of its role in industry. As manufacturing continues to evolve, metal forming machinery will remain essential to building durable, efficient, and innovative products.