Learn the Basics: How Autoclave Machines Ensure Proper Sterilization

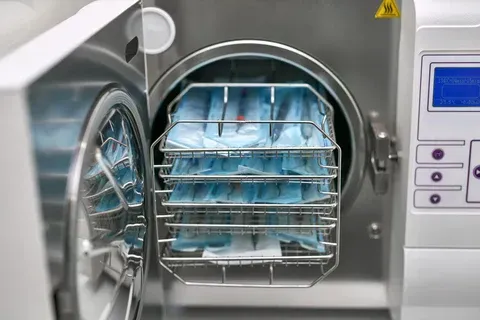

Autoclave machines are specialized devices used to sterilize tools, equipment, and materials using high-pressure steam. They play a key role in environments where eliminating harmful microorganisms is essential. Autoclaves operate by raising temperature and pressure inside a sealed chamber, ensuring that bacteria, viruses, spores, and fungi are effectively destroyed.

This technology exists because ordinary cleaning or low-temperature disinfection cannot eliminate all microbial threats. In settings such as healthcare, laboratories, dental clinics, research centers, and industrial facilities, proper sterilization is necessary to prevent contamination and maintain safety standards.

Autoclaves are available in multiple types—gravity displacement, vacuum autoclaves, horizontal autoclaves, vertical autoclaves, and portable steam sterilizers—each designed for specific applications. Over time, their development has focused on improving sterilization accuracy, safety features, and energy efficiency.

Importance – Why Proper Sterilization With Autoclaves Matters

Autoclave machines are essential because they directly impact health, safety, and quality control. Proper sterilization helps reduce infection risks and ensures safe handling of tools and materials.

Why autoclave sterilization matters today

-

Preventing contamination: Autoclaves help ensure that medical and laboratory instruments are safe for human use.

-

Reducing infection risks: Sterilized tools lower the chances of cross-contamination in hospitals, dental clinics, and diagnostic centers.

-

Supporting research accuracy: In scientific labs, contamination can affect experiments and data reliability.

-

Ensuring product safety: In manufacturing and food processing, sterilized equipment supports clean production environments.

Who relies on autoclave machines

-

Healthcare workers

-

Laboratory technicians

-

Dentists and dental hygienists

-

Industrial engineers

-

Pharmaceutical teams

-

Veterinary professionals

Problems autoclaves help solve

-

Growth of harmful microorganisms

-

Sterilization inconsistencies

-

Limitations of chemical disinfectants

-

Challenges in meeting hygiene regulations

-

Risk of infection in clinical environments

Autoclaves provide a consistent, controlled, and validated method of sterilization that helps organizations meet safety and compliance standards.

Recent Updates – Developments and Trends (2024–2025)

The autoclave industry has seen several updates over the past year due to advancements in healthcare, technology, and laboratory operations.

Key updates in the last year

1. Integration of Smart Monitoring (2024)

New autoclave models feature digital interfaces, remote monitoring, and automated cycle recording. These updates help organizations track sterilization data more accurately.

2. Energy-Efficient Models Introduced (2024)

Manufacturers released low-energy and water-saving autoclaves designed for facilities seeking sustainable solutions.

3. Improved Safety and Compliance Features (Late 2024)

Autoclaves with automatic pressure release, temperature alarms, and self-check diagnostics became more widely adopted across clinics and hospitals.

4. Growth in Portable Autoclaves (Early 2025)

Portable steam sterilizers gained popularity among small clinics, beauty centers, and field laboratories due to their flexibility and compact size.

5. Updated Sterilization Standards in Several Countries (2024–2025)

Many health authorities strengthened guidelines for equipment sterilization processes, increasing the demand for reliable autoclave systems.

Laws or Policies – Regulations Affecting the Use of Autoclave Machines

Autoclave machines operate under strict regulatory guidelines because they affect public health and safety. Regulations ensure that sterilization processes meet minimum safety standards and that machines function reliably.

Healthcare Regulations

-

Many countries require healthcare facilities to maintain sterilization logs for each autoclave cycle.

-

Routine validation and calibration of autoclaves is mandatory in hospitals and dental clinics.

-

Sterile processing departments must follow documented sterilization protocols.

Environmental and Safety Regulations

-

Autoclaves that handle biomedical waste must follow waste management laws, including proper treatment of infectious waste before disposal.

-

Operators must be trained according to workplace safety guidelines for handling high-temperature and high-pressure machinery.

Quality Standards

Most countries follow international sterilization and equipment standards including:

-

ISO 17665 for moist heat sterilization

-

ISO 13485 for medical device quality systems

-

EN standards for healthcare sterilization processes

These policies ensure reliability, minimize sterilization errors, and maintain consistency in clinical and laboratory environments.

Tools and Resources – Helpful Platforms and Supporting Materials

Many digital tools, apps, and resources help facilities manage sterilization, track autoclave processes, and maintain compliance.

Sterilization Management Tools

-

Autoclave cycle recorders – Digital systems that track time, temperature, and pressure.

-

Cloud-based sterilization logs – Ensure proper documentation and reporting.

Monitoring and Validation Tools

-

Biological indicators – Test whether sterilization cycles meet microbial reduction standards.

-

Chemical indicators – Provide visual confirmation of cycle status.

-

Temperature and pressure sensors – Track real-time cycle performance.

Educational Resources

-

WHO Sterilization Guidelines – International standards for infection prevention.

-

CDC Sterilization Resources – Tools for healthcare and laboratory safe practices.

-

ISO Manuals – Guidelines for sterilization quality systems.

Diagnostic and Calibration Apps

-

Some modern autoclave systems offer mobile apps that allow users to:

-

View cycle history

-

Receive maintenance reminders

-

Track system performance

-

Templates and Checklists

-

Daily sterilization checklists

-

Autoclave maintenance logs

-

Equipment inspection forms

-

Sterilization validation sheets

Table: Common Autoclave Types and Their Primary Uses

| Autoclave Type | Key Features | Common Applications |

|---|---|---|

| Gravity Autoclave | Uses gravity to remove air | Dental clinics, small labs |

| Vacuum Autoclave | Removes air with vacuum pump | Hospitals, research facilities |

| Vertical Autoclave | Space-saving steam chamber | Microbiology labs |

| Horizontal Autoclave | Large capacity chambers | Hospitals, pharmaceutical plants |

| Portable Autoclave | Compact and lightweight | Field labs, small clinics |

FAQs – Clear and Helpful Answers

1. What is an autoclave machine used for?

An autoclave is used to sterilize instruments, laboratory materials, and medical tools using pressurized steam. It ensures the removal of microorganisms that standard cleaning cannot eliminate.

2. How does an autoclave work?

An autoclave raises the temperature and pressure inside a chamber to create steam that destroys bacteria, spores, and viruses. Typical cycles reach temperatures of 121–134°C.

3. How long does sterilization take in an autoclave?

Most autoclave cycles take between 15 and 45 minutes, depending on load size, model type, and sterilization requirements.

4. Do autoclaves require regular maintenance?

Yes. Regular servicing, calibration, and routine inspections help ensure that the autoclave operates safely and meets sterilization standards.

5. Can all materials be sterilized in an autoclave?

No. Heat-sensitive plastics, certain chemicals, and electronic devices may not be suitable for autoclaving. Each item should be checked for autoclave compatibility.

Final Thoughts

Autoclave machines remain a fundamental part of proper sterilization in medical, laboratory, and industrial environments. Their ability to use high-pressure steam ensures consistent and reliable elimination of harmful microorganisms. Understanding the types, uses, regulations, and supportive tools helps users operate autoclaves safely and effectively. With advancements in digital monitoring, eco-friendly designs, and updated regulations, autoclave technology continues to support global safety and hygiene standards.