Industrial Electric Forklifts Explained: An Overview, Basics, and Key Facts

Industrial electric forklifts are battery-powered vehicles designed to lift, carry, and stack loads within warehouses, factories, ports, and distribution centers. They exist to address the need for efficient material movement in controlled environments where precision, safety, and indoor air quality are essential.

Unlike internal combustion models, electric forklifts rely on electric motors and rechargeable batteries. This design emerged as industries expanded indoors and required equipment that produced minimal noise and zero direct exhaust emissions. Over time, electric forklift technology has evolved alongside advancements in batteries, power electronics, and industrial automation.

Today, industrial electric forklifts are a core component of modern material handling systems. They are commonly used for pallet movement, shelving operations, container handling, and assembly-line support across manufacturing and logistics environments.

Importance: Why This Topic Matters Today

Industrial electric forklifts matter because they directly influence productivity, workplace safety, and environmental performance in industrial settings. Their role extends beyond simple lifting tasks and affects multiple stakeholders across the supply chain.

They are especially relevant for:

-

Warehouse operators managing high-volume inventory

-

Manufacturing facilities requiring precise internal transport

-

Logistics hubs handling time-sensitive goods

-

Organizations focused on cleaner indoor operations

Key problems they help address include:

-

Reducing indoor air pollution

-

Lowering operational noise levels

-

Improving maneuverability in confined spaces

-

Supporting consistent material flow in automated environments

As global supply chains grow more complex, electric forklifts help maintain efficiency while aligning with sustainability goals and stricter environmental expectations. Their relevance continues to increase as industries seek reliable equipment compatible with digital monitoring and energy management systems.

Recent Updates: Trends and Developments in the Past Year

Over the past year, several notable trends have shaped the industrial electric forklift landscape.

Battery technology has seen significant progress. Lithium-ion batteries have gained wider adoption during 2024–2025 due to faster charging cycles, longer lifespan, and reduced maintenance requirements compared to traditional lead-acid batteries.

Another update is the integration of smart monitoring systems. Many electric forklifts now include sensors and telematics that track usage patterns, battery health, and operating conditions. These features support predictive maintenance and data-driven fleet management.

Automation compatibility has also expanded. Electric forklifts are increasingly designed to work alongside automated guided vehicles (AGVs) and warehouse management systems, enabling smoother transitions toward semi-automated operations.

Energy efficiency standards have tightened in several regions, encouraging manufacturers to improve motor efficiency, regenerative braking, and power control systems.

Laws or Policies: Regulatory Influence on Electric Forklifts

Industrial electric forklifts are influenced by workplace safety laws, environmental regulations, and equipment standards that vary by country. In India and many other regions, occupational safety guidelines emphasize proper training, equipment certification, and safe load handling.

Environmental policies promoting reduced emissions indirectly support electric forklift adoption in indoor industrial spaces. Noise control regulations in urban industrial zones also favor quieter electric equipment.

International standards such as ISO and IEC guidelines affect forklift design, electrical safety, battery handling, and charging infrastructure. Compliance with these standards ensures interoperability and safer operation across borders.

Government-led industrial modernization programs and energy efficiency initiatives further encourage the use of electrically powered material handling equipment within factories and logistics centers.

Tools and Resources: Helpful References and Practical Aids

Understanding and managing industrial electric forklifts is supported by a range of tools and resources used across the industry.

Commonly referenced resources include:

-

Forklift load capacity calculators for safe operation

-

Battery performance monitoring dashboards

-

Energy consumption tracking tools

-

Digital maintenance logs and inspection checklists

-

Industry standards documentation from ISO and IEC

-

Educational guides on warehouse layout optimization

These tools assist operators and planners in improving safety, understanding equipment limitations, and aligning forklift use with broader operational goals.

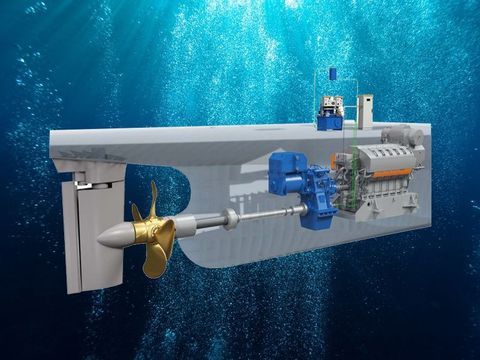

Technical Snapshot: Key Components and Functions

The table below summarizes the core components of an industrial electric forklift and their primary roles.

| Component | Function |

|---|---|

| Electric Motor | Provides controlled lifting and driving power |

| Battery System | Stores electrical energy for operation |

| Controller Unit | Manages power distribution and speed |

| Mast Assembly | Raises and lowers loads vertically |

| Counterweight | Balances loads for stability |

| Regenerative Braking | Recovers energy during deceleration |

This simplified overview highlights how electric forklifts combine mechanical and electrical systems to achieve reliable material handling.

Operational Comparison: Electric vs. Internal Combustion

A basic comparison helps clarify why electric forklifts are preferred in many industrial environments.

| Factor | Electric Forklifts | Combustion Forklifts |

|---|---|---|

| Emissions | None at point of use | Present |

| Noise Level | Low | Higher |

| Indoor Suitability | High | Limited |

| Energy Source | Battery | Fuel |

| Precision Control | High | Moderate |

This comparison illustrates why electric forklifts align well with indoor and environmentally controlled operations.

FAQs: Common Questions Answered Clearly

What environments are industrial electric forklifts best suited for?

They are ideal for indoor warehouses, factories, cold storage facilities, and enclosed logistics centers where air quality and noise control are important.

How long does an electric forklift typically operate on one charge?

Operating time varies based on battery type, load weight, and usage intensity. Many modern systems support full-shift operation under standard conditions.

Are electric forklifts suitable for heavy loads?

Yes, industrial electric forklifts are available in a wide range of load capacities, including models designed for heavy-duty industrial use.

What safety features are commonly included?

Typical features include load sensors, speed limiters, stability control systems, and emergency power cutoffs to enhance safe operation.

How do electric forklifts support sustainability goals?

They reduce direct emissions, support energy efficiency initiatives, and integrate well with renewable-powered charging systems.

Conclusion: Key Takeaways for General Understanding

Industrial electric forklifts are a foundational element of modern material handling. Their development reflects broader industrial priorities such as efficiency, safety, and environmental responsibility. By combining electric power systems with robust mechanical design, they meet the demands of contemporary warehouses and manufacturing facilities.

Recent advancements in batteries, monitoring technologies, and automation compatibility have further strengthened their role. Regulatory frameworks and industrial standards continue to shape their design and application, ensuring safer and more consistent use worldwide.