Helpful Advice for Maintaining Your Valve Seat Cutting Machine

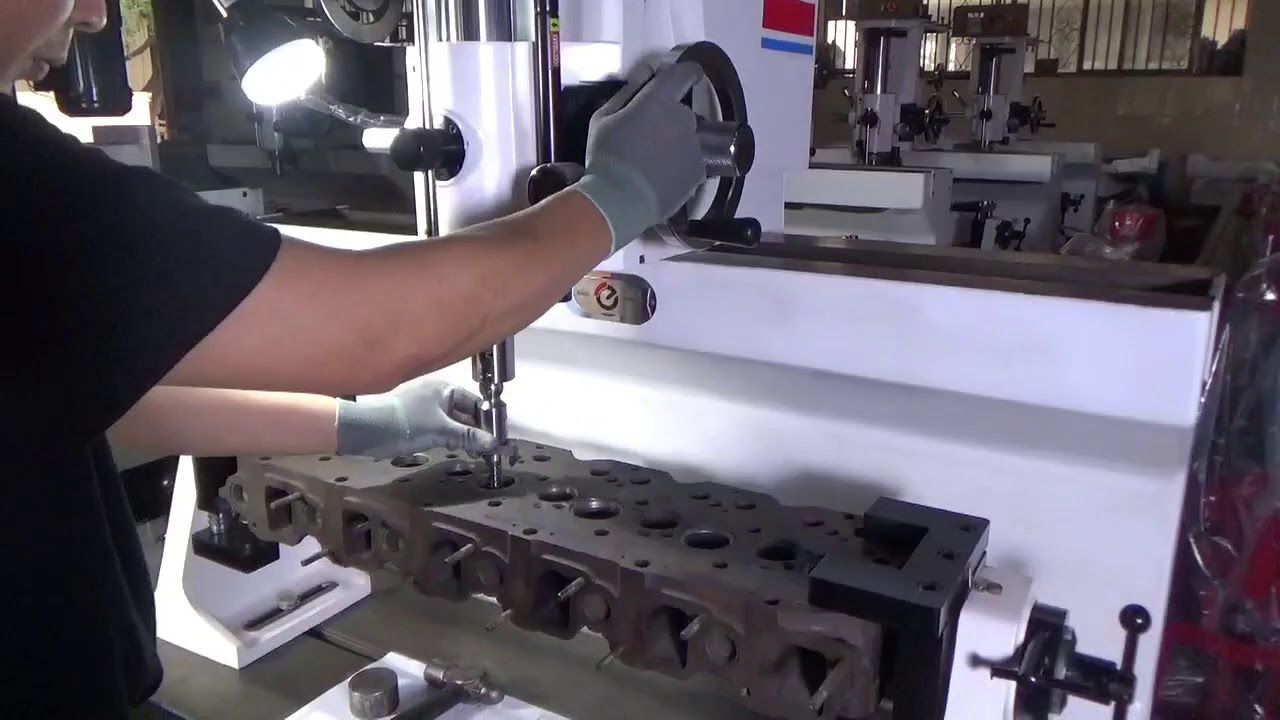

A valve seat cutting machine is an essential tool used in automotive workshops, engine rebuilding facilities, and manufacturing units. Its main purpose is to cut, shape, or refurbish valve seats in engine cylinder heads to ensure proper sealing and combustion efficiency.

Valve seats must be precisely machined to allow the valve to fit correctly, minimize leakage, and maintain engine performance. Over time, wear, carbon deposits, and thermal stress can damage these seats, requiring accurate re-cutting or resurfacing.

These machines exist because manual cutting is time-consuming, less consistent, and prone to human error. Modern valve seat cutting machines offer precision control, automated adjustments, and durable cutting tools that improve consistency and reduce downtime.

Importance – Why Maintaining a Valve Seat Cutting Machine Matters Today

Proper maintenance of a valve seat cutting machine is crucial for both performance and safety. A well-maintained machine produces accurate cuts, extends tool life, and prevents unexpected breakdowns.

Why it matters today:

-

Precision demands: Modern engines require higher accuracy in valve seating for fuel efficiency and emission standards.

-

Increased workload: Workshops processing high engine volumes rely on machines that operate consistently without delays.

-

Cost control: Regular maintenance reduces repair expenses and extends machine lifespan.

-

Safety: Faulty equipment may cause misalignment, tool breakage, or injury risks.

Who this affects:

-

Automotive repair shops

-

Engine rebuilding workshops

-

Industrial machinery maintenance teams

-

Technicians working with high-precision engine components

-

Small manufacturing units with in-house valve machining

Problems maintenance helps solve:

-

Inaccurate valve seating causing engine inefficiency

-

Increased tool wear leading to higher costs

-

Machine vibration or instability

-

Frequent downtime during peak workloads

Recent Updates – Trends and Improvements (2024–2025)

Recent developments have enhanced how valve seat cutting machines operate and how they should be maintained:

-

Digital Calibration Systems (2024): Newer machines include built-in sensors that detect misalignment and guide technicians through calibration.

-

Stronger Carbide and Diamond Tooling: Cutting inserts now provide longer life when machining hardened seats.

-

Automated Lubrication Options: Some models introduced automated oiling systems to maintain spindle smoothness.

-

Improved Dust Collection Attachments (2025): Reduces debris accumulation that can affect machine accuracy.

-

Maintenance Apps Released by Manufacturers: These apps provide reminders, troubleshooting tips, and digital logs for maintenance schedules.

These trends help technicians maintain machines more efficiently while improving cut quality and reducing manual errors.

Laws or Policies – Regulations Affecting Operation and Maintenance

Maintenance practices for valve seat cutting machines can be influenced by national and regional regulations, particularly in industrial and automotive environments:

Workplace Safety Regulations

-

Machines must have proper guards and emergency stops.

-

Operators must follow safety guidelines under regional occupational safety rules (e.g., OSHA in the U.S., local factory acts in other countries).

Environmental Policies

-

Metal chips, cutting fluids, and debris must be disposed of according to waste management standards.

-

Dust extraction systems are required in some regions to reduce workplace air pollution.

Energy Efficiency Requirements

-

Industrial facilities may be encouraged or required to use energy-efficient equipment or conduct routine maintenance to reduce electrical consumption.

Tool and Machinery Standards

-

Cutting tools and replacement parts must meet quality standards to ensure safe machining.

-

Machine calibration and safety inspections may be required by local guidelines for certified workshops.

Awareness of these policies ensures safe operation and compliance with industrial standards.

Tools and Resources – Useful Support for Maintenance

Several tools, digital platforms, and reference materials help technicians maintain valve seat cutting machines effectively.

Maintenance Tools

-

Dial indicators: To check spindle runout and alignment.

-

Torque wrenches: For securing fixtures without over-tightening.

-

Cleaning brushes and air blowers: To remove dust and metal chips.

-

Lubricants and greases: For spindle and guideway maintenance.

-

Coolant testers: To ensure cutting fluids remain effective.

Digital Tools and Apps

-

Manufacturer maintenance apps: Provide reminders, tutorials, and troubleshooting steps.

-

Engine machining reference apps: Offer valve seating angles, torque values, and specifications.

-

Calibration calculators: Assist in setting proper cutting depths and angles.

Educational Resources

-

Manufacturer manuals: Detailed instructions for maintenance schedules.

-

Online technician forums: Discussions on common machine issues and solutions.

-

Video tutorials: Demonstrate proper cleaning, lubrication, and tool replacement techniques.

Using these tools ensures a systematic and informed maintenance approach.

Practical Tips for Maintaining a Valve Seat Cutting Machine

| Tip | What To Do | Why It Matters |

|---|---|---|

| Clean After Every Use | Remove chips, dust, and residue from the machine | Prevents misalignment and wear |

| Lubricate Moving Parts | Apply oil or grease to spindles and guideways | Reduces friction and extends component life |

| Check Tool Condition | Inspect inserts and replace when dull or chipped | Ensures precise cutting and reduces load on the machine |

| Verify Alignment Regularly | Use dial indicators to check spindle and table alignment | Maintains consistent seat angles and accurate cuts |

| Monitor Machine Vibration | Address loose bolts, worn bearings, or imbalanced cutters | Prevents tool breakage and damage to the workpiece |

| Maintain Proper Coolant Levels | Replace or filter coolant as needed | Prevents overheating and improves tool longevity |

| Keep Maintenance Records | Log services, repairs, and part replacements | Helps predict future maintenance needs |

Consistent application of these tips improves machine reliability and cut quality.

FAQs

How often should I clean a valve seat cutting machine?

It is recommended to clean the machine after every use, focusing on chip removal and wiping down exposed surfaces to prevent buildup.

What are signs that alignment is off?

Misalignment may cause uneven cuts, chatter marks, or difficulty maintaining accurate angles. Regularly checking alignment helps prevent these issues.

Do cutting tools need frequent replacement?

Tool life depends on material hardness and usage frequency. Dull or chipped inserts must be replaced immediately to avoid damaging valve seats.

Can improper lubrication damage the machine?

Yes. Without lubrication, friction increases, leading to premature wear of spindles, guideways, and bearings.

Is professional servicing necessary?

For complex calibration or internal repairs, professional servicing is recommended. Routine cleaning and lubrication can be performed in-house.

Final Thoughts

Maintaining a valve seat cutting machine is essential for ensuring precise machining, reducing downtime, and extending the machine’s operational life. By following a structured maintenance routine—cleaning, lubrication, alignment checks, and tool inspection—technicians can keep the machine running smoothly and avoid costly repairs.

Staying informed about recent updates, using reliable tools, and following applicable safety regulations help create a more efficient and safer workshop environment. Consistent care not only improves accuracy and productivity but also supports long-term engine performance in the vehicles serviced.