Explore Shock Absorber Manufacturing: Complete Overview, Information & Practical Tips

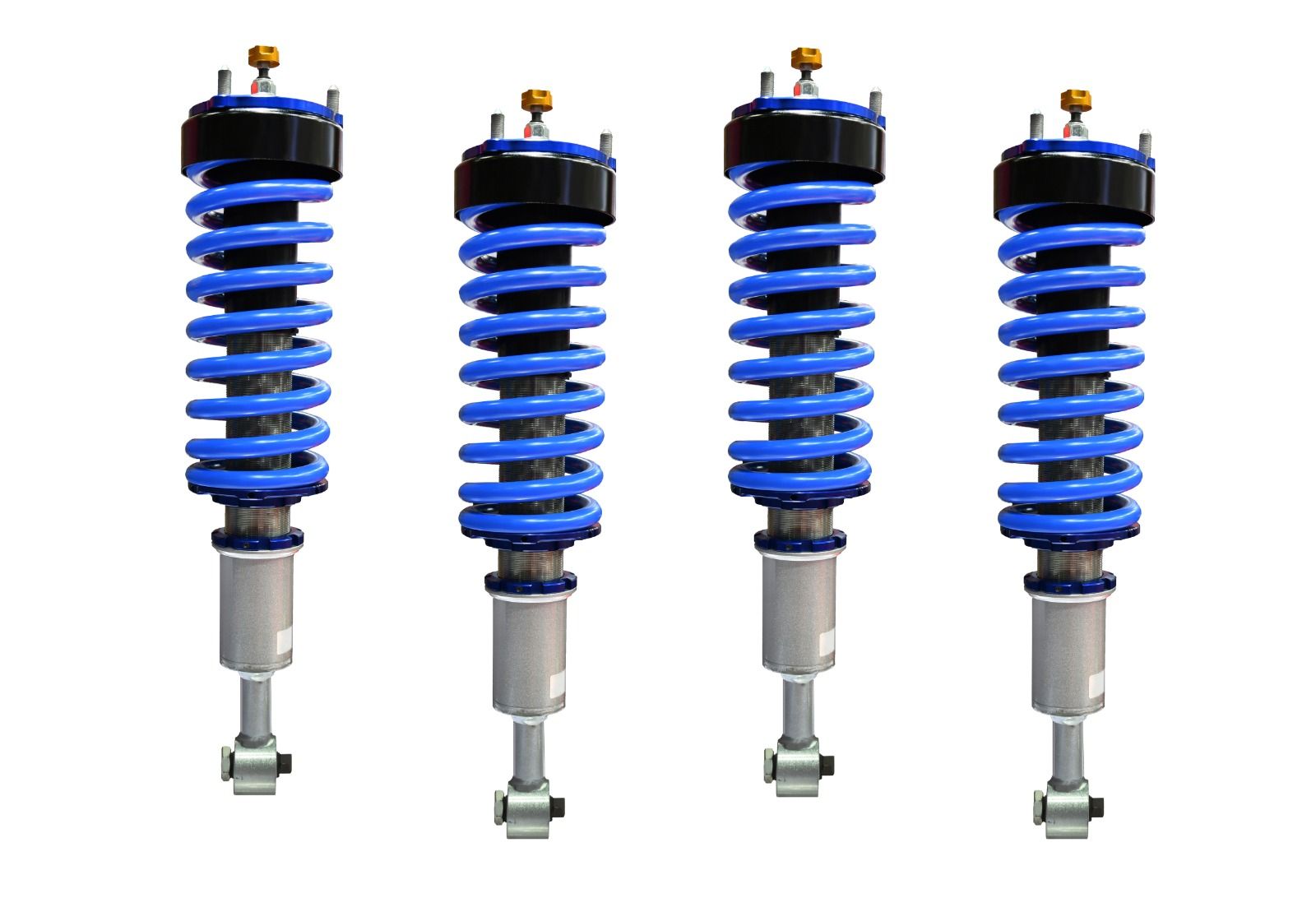

Shock absorbers manufacturing refers to the engineering, design, and production processes used to create components that control suspension movement in vehicles and industrial machines. Shock absorbers exist to improve stability, manage vibrations, and enhance control during motion. They convert kinetic energy into heat and ensure smoother, safer operation across various applications.

The concept originated from the need to reduce excessive bounce and improve handling in early automotive systems. Over time, the industry has evolved with advanced materials, precision machining, and specialized assembly methods. Manufacturers use hydraulic, pneumatic, and electronic technologies to create shock absorbers suitable for two-wheelers, passenger vehicles, heavy commercial vehicles, rail systems, off-road machinery, and industrial equipment.

Today, shock absorber manufacturing focuses on performance consistency, durability, and adaptability to different terrains and load conditions. Modern facilities use automation, computer-aided design, and robotics to improve product reliability and bring efficiency to production lines.

Importance: Why Shock Absorber Manufacturing Matters

Shock absorber manufacturing plays a critical role in mobility, transportation safety, and mechanical reliability. It matters today for several important reasons:

Key Benefits

-

Enhances vehicle stability by reducing excessive movement during driving.

-

Improves passenger comfort by controlling vibrations and bumps.

-

Supports road safety through better braking, cornering, and traction.

-

Extends equipment life by lowering stress on mechanical components.

-

Improves energy efficiency in machines by controlling oscillations.

Who It Affects

-

Automotive OEMs

-

Transport fleets

-

Mechanics and workshop operators

-

Industrial machine manufacturers

-

Railway system engineers

-

Agricultural and construction equipment operators

Problems It Helps Solve

-

Unstable vehicle handling

-

Increased wear on suspension systems

-

Noise, vibration, and harshness (NVH) issues

-

Reduced performance on uneven or off-road conditions

-

Higher maintenance frequency due to uncontrolled mechanical stress

Reliable shock absorber manufacturing ensures smoother transportation, safer mobility, and longer equipment lifespan across industries.

Recent Updates: Trends and Developments in the Last Year

The past year has seen notable advancements influenced by digital transformation, material innovation, and changing mobility trends.

Key Updates

-

Rise of semi-active and adaptive dampers :

These systems use electronic controls to adjust damping force in real time. Demand has grown in premium cars, electric vehicles, and performance motorcycles. -

Increased use of lightweight materials :

Manufacturers are adopting aluminum alloys, composite tubes, and advanced seals to improve efficiency and reduce suspension weight. -

Integration of AI-based design tools :

AI and simulation-driven engineering now shorten design cycles and optimize fluid dynamics, piston design, and valve performance. -

Growth of EV-specific shock absorbers :

Electric vehicles require different suspension characteristics because of battery weight and torque delivery. Manufacturers are creating specialized dampers to meet these needs. -

Greater automation in production lines :

Robotic welding, precision machining, smart sensors, and digital quality control systems are becoming standard in modern factories. -

Sustainability-focused materials :

More manufacturers are exploring improved fluid formulations and recyclable components due to global environmental expectations.

These updates indicate a shift toward precision engineering, digital tools, and sustainability across the entire shock absorber manufacturing landscape.

Laws or Policies: Regulations Affecting Shock Absorber Manufacturing

Shock absorber production is influenced by safety standards, material guidelines, and performance testing regulations. While details vary by country, common policies include:

Automotive Safety Standards

-

ISO 9001 & IATF 16949:

Widely used for quality management in automotive component manufacturing. -

ISO 6624 & ISO 10844:

Standards related to piston ring technology, testing environments, and noise assessments. -

FMVSS Standards (USA):

Cover vehicle performance and component guidelines impacting suspension systems.

Environmental and Material Regulations

-

Restrictions on hazardous substances in production, such as:

-

REACH (EU)

-

RoHS guidelines

-

-

Fluid disposal and waste management rules enforced by environmental agencies.

Testing Requirements

Shock absorbers must meet durability, vibration, temperature resistance, and pressure endurance benchmarks. These requirements apply across regions and ensure consistent product performance.

Industry-Specific Policies

-

Heavy equipment and railway sectors often require compliance with sector-specific mechanical, thermal, and operational standards.

-

Countries with growing automotive manufacturing hubs (India, Germany, Japan, Thailand, USA, Mexico) require certification for assembly and performance testing.

Regulations ensure that shock absorber manufacturing remains reliable, standardized, and aligned with global safety expectations.

Tools and Resources: Useful Platforms, Calculators, and Guides

Several tools and resources help engineers, students, and industry professionals understand and work with shock absorber manufacturing more effectively.

Design and Simulation Tools

-

ANSYS Mechanical – Helps simulate damping characteristics and material behavior.

-

SolidWorks Motion – Used for designing internal components and analyzing movement.

-

MATLAB Simulink – Assists in modeling dynamic behavior and testing system responses.

-

Autodesk Inventor – Commonly used to design assembly structures.

Technical Standards and Documentation

-

SAE International Standards – Guidelines for automotive suspension components.

-

ISO Standards Database – Documents covering shock absorber testing, quality, and manufacturing.

-

EngineeringToolBox – Reference data on mechanical components and materials.

Learning Platforms

-

Coursera – Mechanical engineering fundamentals and automotive engineering courses.

-

MIT OpenCourseWare – Free engineering theory resources.

-

Khan Academy (Physics) – Basic principles on motion and energy absorption.

Industry Resources

-

Automotive Engineering magazines – Updates on materials and technology innovations.

-

ResearchGate – Studies on damping systems and material optimization.

-

Automotive OEM technical publications – Provide insights into component integration.

Reference Table: Key Elements in Shock Absorber Manufacturing

| Component | Purpose | Key Consideration |

|---|---|---|

| Piston & Valve | Controls fluid flow | Precision machining |

| Cylinder Tube | Holds fluid and components | Material strength |

| Seal & Rod Guide | Prevents leakage | Temperature resistance |

| Piston Rod | Transfers motion | Surface finish |

| Fluid (Oil/Gas) | Provides damping action | Stability and consistency |

These tools help improve design accuracy, enhance understanding, and support consistent production quality.

FAQs

What is the primary purpose of a shock absorber?

A shock absorber controls suspension movement and manages vibrations to ensure stable, smooth, and safe operation of vehicles and machines.

How are shock absorbers tested during manufacturing?

Manufacturers use endurance tests, vibration rigs, pressure tests, temperature cycling, and performance measurement against standardized damping curves.

What materials are commonly used in shock absorber production?

Steel, aluminum alloys, composite tubes, high-precision seals, and specialized hydraulic or gas fluids are typically used.

What are the main types of shock absorbers?

Common types include hydraulic dampers, gas-charged shock absorbers, twin-tube designs, mono-tube systems, and electronically adjustable dampers.

Why is precision important in shock absorber manufacturing?

Precision ensures consistent performance, reduces noise and vibration, and helps maintain durability under varying load and temperature conditions.

Conclusion

Shock absorber manufacturing remains an essential part of modern mobility and industrial engineering. The topic continues to evolve as materials, automation technologies, and digital design tools advance. Understanding the context, importance, recent updates, regulations, and available resources helps engineers, students, and industry professionals gain clarity about how these components are developed and used.

With global industries moving toward smarter vehicles, electric mobility, and more durable machinery, shock absorber manufacturing will continue to grow in relevance. The field is shaped by strict quality standards, new materials, and ongoing innovation that supports safer and more reliable systems across transportation and industrial sectors.