Explore PCB Equipment: A Complete Guide with Key Facts and Insights

Printed Circuit Boards (PCBs) are the foundation of nearly every electronic device today. From smartphones and medical instruments to industrial machines and electric vehicles, PCBs provide the electrical connections that allow components to communicate effectively. PCB equipment refers to the machinery and tools used in designing, fabricating, assembling, and testing these boards.

Understanding PCB equipment is essential not only for electronics professionals but also for students, innovators, and industries exploring automation, IoT devices, and sustainable electronics. This guide explores what PCB equipment is, why it’s important, the latest developments, and what tools and resources can help professionals and learners alike.

Context

PCB equipment encompasses the wide range of tools used in printed circuit board manufacturing—from initial design to final testing. These include:

-

Design and layout tools such as CAD and EDA software (e.g., Altium Designer, KiCad, Eagle) used for circuit design and schematics.

-

Fabrication machines like drilling, etching, lamination, and plating machines used to build physical PCBs.

-

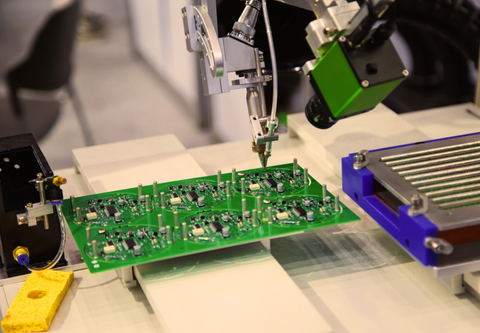

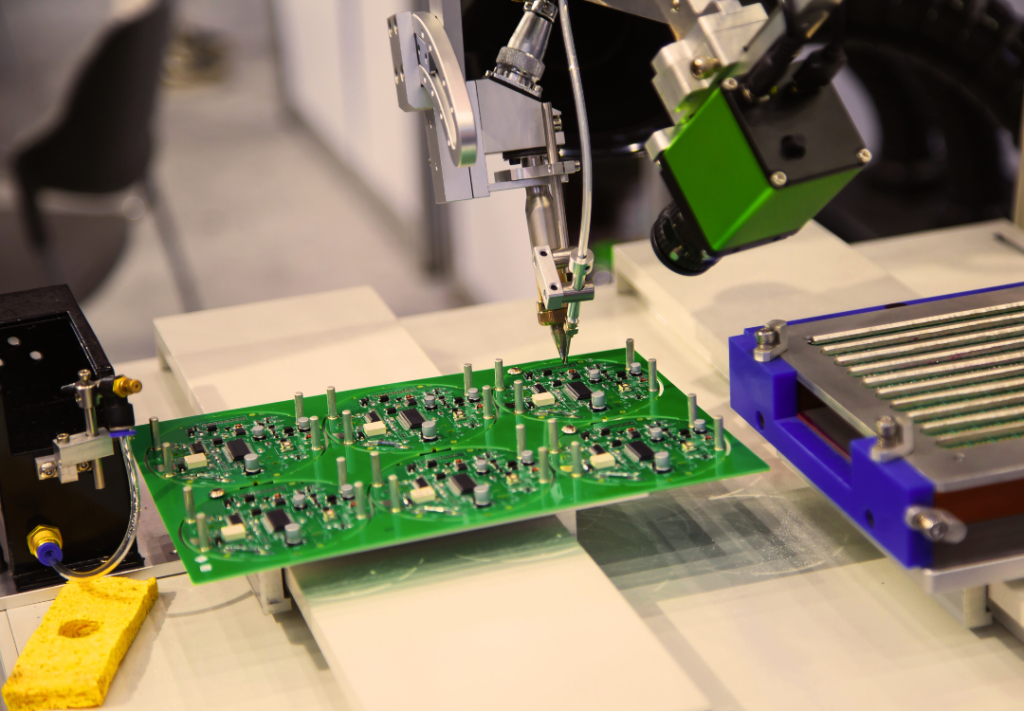

Assembly equipment including pick-and-place machines, soldering stations, and reflow ovens.

-

Inspection and testing tools such as automated optical inspection (AOI) systems, flying probe testers, and X-ray inspection machines.

PCBs exist to ensure reliability, miniaturization, and efficient performance in electronics. As devices become smaller and faster, the demand for high-precision and automated PCB equipment continues to rise.

Importance

PCB equipment is vital in almost every electronics-related industry. It affects:

-

Manufacturers: Helps improve accuracy, reduce waste, and speed up production.

-

Engineers and Designers: Enables the creation of complex multilayer boards for modern gadgets.

-

Students and Innovators: Provides tools for learning and prototyping.

-

Industries: Supports sectors like automotive, healthcare, aerospace, telecommunications, and renewable energy.

The importance of PCB equipment has increased due to:

-

Rapid Technological Growth: Emerging technologies like 5G, AI, and IoT demand high-density and high-speed circuit designs.

-

Miniaturization of Devices: Smaller gadgets need compact, multi-layer boards that require precision tools.

-

Sustainability Goals: Modern PCB manufacturing is moving toward eco-friendly and lead-free production methods.

| Industry Application | PCB Equipment Use | Example Equipment |

|---|---|---|

| Consumer Electronics | Compact circuits for gadgets | SMT pick-and-place, reflow oven |

| Automotive | Control systems, sensors | AOI systems, PCB testers |

| Healthcare | Medical devices | Cleanroom assembly tools |

| Aerospace | Navigation & control | High-reliability inspection systems |

| Renewable Energy | Power electronics | Solder paste printers, laminators |

PCB equipment helps ensure reliability and quality—two pillars of modern electronics design.

Recent Updates

Over the past year, PCB manufacturing has seen several important changes and advancements:

-

Automation and AI Integration (2024–2025): Manufacturers increasingly use AI-driven inspection and predictive maintenance tools to improve quality and reduce downtime.

-

Sustainability Focus (2025): New eco-friendly materials and waste management technologies are being adopted, including water-based flux and recyclable laminates.

-

Flexible and Wearable PCBs: The demand for flexible circuits has surged in 2024–2025, especially in wearable devices and automotive interiors.

-

Global Supply Chain Resilience: After 2024’s supply chain disruptions, companies are investing in regional PCB production facilities, especially in India, Vietnam, and Mexico.

-

AI-Based Design Tools: Software like Altium 365 and Autodesk Fusion 360 are now offering AI assistance for schematic verification and layout optimization.

These developments highlight how PCB equipment is evolving to meet the needs of faster, smaller, and more sustainable electronics.

Laws or Policies

PCB manufacturing and equipment use are influenced by several regulations and standards designed to ensure safety, quality, and environmental protection.

-

RoHS (Restriction of Hazardous Substances): Limits the use of harmful materials like lead and mercury in PCBs.

-

REACH Regulation (EU): Requires manufacturers to identify and manage chemical substances used in PCB processes.

-

IPC Standards: Global manufacturing standards such as IPC-A-610 and IPC-2221 ensure design and assembly quality.

-

Indian Government Initiatives: Programs like Make in India and the PLI Scheme for Electronics Manufacturing (2023–2025) are encouraging domestic PCB production by providing infrastructure and tax incentives.

-

Energy Efficiency Laws: Many countries now require PCB production facilities to adopt cleaner, more energy-efficient processes.

These policies promote responsible manufacturing and help maintain global competitiveness while aligning with sustainability goals.

Tools and Resources

Professionals and learners can benefit from various tools, software, and learning platforms related to PCB equipment and design.

Design and Simulation Tools

-

Altium Designer: Professional PCB design and layout software.

-

KiCad: Open-source design tool for schematic capture and board layout.

-

Autodesk Eagle: Popular with startups and small-scale designers.

-

Proteus: Used for circuit simulation and microcontroller testing.

Manufacturing and Assembly Tools

-

Pick-and-Place Machines: Automate component placement with precision.

-

Reflow Ovens: Used for soldering surface-mounted components.

-

AOI Systems: Detect defects using optical and AI technologies.

-

Laser Drilling Machines: Enable high-precision holes for multilayer PCBs.

Educational Resources

-

IPC Online Learning: Offers training on design and quality standards.

-

Coursera & Udemy Courses: Provide practical PCB design tutorials.

-

PCBWay & JLCPCB Platforms: Useful for prototype fabrication and testing support.

Data and Analysis Tools

-

OrCAD: Simulation and signal integrity analysis.

-

Mentor Graphics PADS: For complex, multilayer PCB projects.

| Category | Tool Name | Purpose |

|---|---|---|

| Design | Altium Designer | Professional PCB design |

| Simulation | Proteus | Circuit and microcontroller testing |

| Learning | IPC Online | Certification and education |

| Assembly | Pick-and-place | Automated component installation |

| Inspection | AOI System | Defect detection and analysis |

These tools and resources make PCB design and production more efficient, accurate, and accessible to both professionals and learners.

FAQs

What is PCB equipment used for?

PCB equipment is used to design, manufacture, assemble, and inspect printed circuit boards, which connect and support electronic components in devices.

How is PCB equipment evolving in 2025?

Recent trends include automation, AI-assisted design, and sustainable materials, helping manufacturers improve speed, quality, and environmental compliance.

Is PCB manufacturing regulated?

Yes. PCB production follows international standards such as RoHS, REACH, and IPC to ensure safety and limit environmental impact.

What industries rely most on PCB equipment?

Electronics, automotive, aerospace, healthcare, telecommunications, and renewable energy sectors depend heavily on PCB equipment for production and innovation.

Where can beginners learn PCB design and equipment basics?

Beginners can explore free resources like KiCad tutorials, IPC training modules, and Coursera’s PCB design courses to understand fundamentals and workflows.

Conclusion

PCB equipment plays a foundational role in the global electronics ecosystem. From precision drilling to automated inspection, each piece of equipment contributes to the creation of reliable, high-performance electronic products.

As industries continue to innovate in 2025 and beyond with trends like AI integration, sustainability, and flexible electronics the importance of modern PCB equipment will only grow. By staying informed about the latest technologies, tools, and regulations, both professionals and newcomers can play a meaningful role in the evolving world of electronics manufacturing.