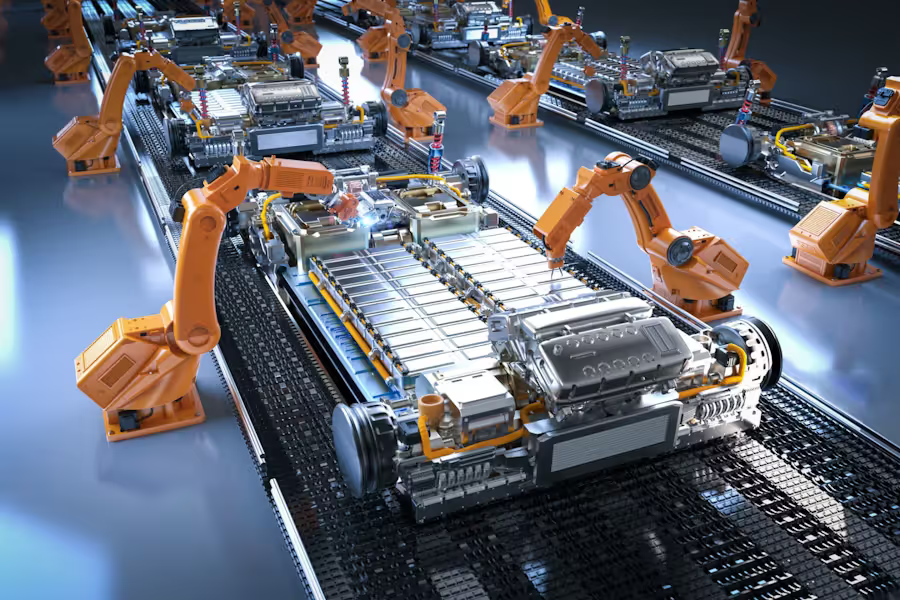

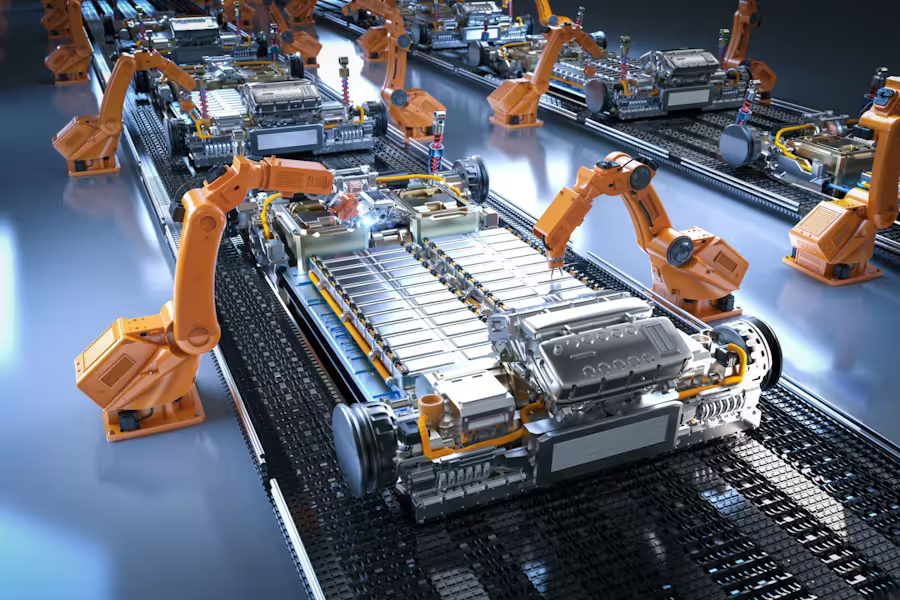

The demand for advanced battery manufacturing machines has grown in recent years due to the rapid adoption of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. As industries continue to focus on sustainability and clean energy, battery manufacturing is becoming a central component of global industrial growth.

Importance

Understanding battery manufacturing machines matters because they directly influence energy efficiency, product reliability, and industrial competitiveness.

Why it matters today:

-

Growing EV adoption is creating massive demand for large-scale battery production.

-

Renewable energy systems require high-capacity batteries for grid storage.

-

Electronics manufacturers rely on precision battery production to ensure safety and performance.

Who it affects:

-

Battery producers and technology companies

-

Automotive and energy sectors

-

Government agencies promoting clean energy initiatives

-

Researchers and engineers working on next-generation energy solutions

Problems it solves:

-

Reduces production errors and defects

-

Increases battery life cycles through precise assembly

-

Enables mass production to meet global energy needs

-

Supports clean energy goals with efficient battery systems

Recent Updates

In the past year, several updates have shaped the battery manufacturing sector:

-

January 2024: Global EV battery production exceeded 1.5 terawatt-hours, driving investment in automated battery assembly lines.

-

May 2024: Advances in dry electrode coating technology reduced production energy consumption by up to 20%.

-

July 2024: Multiple companies introduced AI-powered quality control systems that detect defects in real time during assembly.

-

November 2024: Reports showed increased adoption of solid-state battery production machines, paving the way for safer and higher-capacity batteries.

These updates highlight how battery manufacturing machines are evolving with new technologies, making production faster, safer, and more environmentally friendly.

Laws or Policies

Government policies worldwide play a major role in shaping battery manufacturing and related machines:

-

India: The Production Linked Incentive (PLI) scheme encourages battery manufacturers to adopt advanced machinery to meet local and export demands.

-

European Union: Regulations require sustainable battery production practices, pushing industries to use energy-efficient machines and recyclable materials.

-

United States: Tax incentives under the Inflation Reduction Act support domestic battery production, encouraging investment in high-precision manufacturing equipment.

-

China: National programs fund research into smart manufacturing for batteries, reinforcing its leadership in the global battery supply chain.

These rules ensure that machines used in production meet safety, environmental, and efficiency standards, creating a competitive but regulated environment for manufacturers.

Tools and Resources

Several tools and resources can help individuals and organizations understand battery manufacturing machines more effectively:

-

Websites:

-

International Energy Agency (IEA) – Reports on battery production trends

-

U.S. Department of Energy – Research on energy storage and battery technologies

-

European Battery Alliance – Policy and innovation insights

-

-

Software and Apps:

-

Battery Design Studio – Simulation for battery design and machine setup

-

MATLAB Energy Toolbox – Modeling of energy storage systems

-

AI-based predictive maintenance tools – Monitor machine health in real-time

-

-

Templates and Calculators:

-

Energy density calculators for battery capacity planning

-

Manufacturing process flow templates for industrial planning

-

Cost modeling spreadsheets (for machine usage efficiency, not pricing)

-

These resources help researchers, engineers, and companies improve understanding and optimize processes related to battery manufacturing.

Industry Insights Table

| Battery Type | Common Machines Used | Key Applications |

|---|---|---|

| Lithium-Ion | Electrode coating, winding, assembly | EVs, laptops, grid storage |

| Lead-Acid | Pasting, curing, formation machines | Automotive, backup power |

| Nickel-Metal Hydride | Electrode preparation, sealing units | Hybrid vehicles, electronics |

| Solid-State | Thin-film deposition, dry processing | Next-gen EVs, aerospace |

FAQs

Q1. What is a battery manufacturing machine?

A battery manufacturing machine is equipment designed to produce batteries by automating steps such as material preparation, electrode processing, cell assembly, and testing.

Q2. Why are advanced machines important for battery production?

They improve safety, reduce defects, and increase efficiency, which is critical in industries like electric vehicles and renewable energy storage.

Q3. What are the main types of batteries made using these machines?

Lithium-ion, lead-acid, nickel-metal hydride, and emerging solid-state batteries are commonly produced.

Q4. How are policies influencing battery machine adoption?

Government incentives and environmental regulations encourage companies to adopt sustainable, energy-efficient machines for compliance and competitiveness.

Q5. What trends are shaping the future of battery manufacturing machines?

Automation, AI-driven defect detection, solid-state battery production, and energy-efficient processes are major trends.

Conclusion

Battery manufacturing machines form the backbone of modern energy solutions. From electric vehicles to renewable energy storage, these machines ensure that batteries are produced efficiently, safely, and at scale. Recent updates show rapid innovation, with AI, automation, and sustainable practices reshaping the industry. Policies worldwide further encourage manufacturers to adopt advanced technology, while tools and resources support research and optimization.

By understanding these machines, their importance, and their future direction, stakeholders can stay informed and adapt to one of the most dynamic and essential industries of today.