CO2 Laser Cutting Machines: Complete Guide, Basics, Insights & Practical Tips

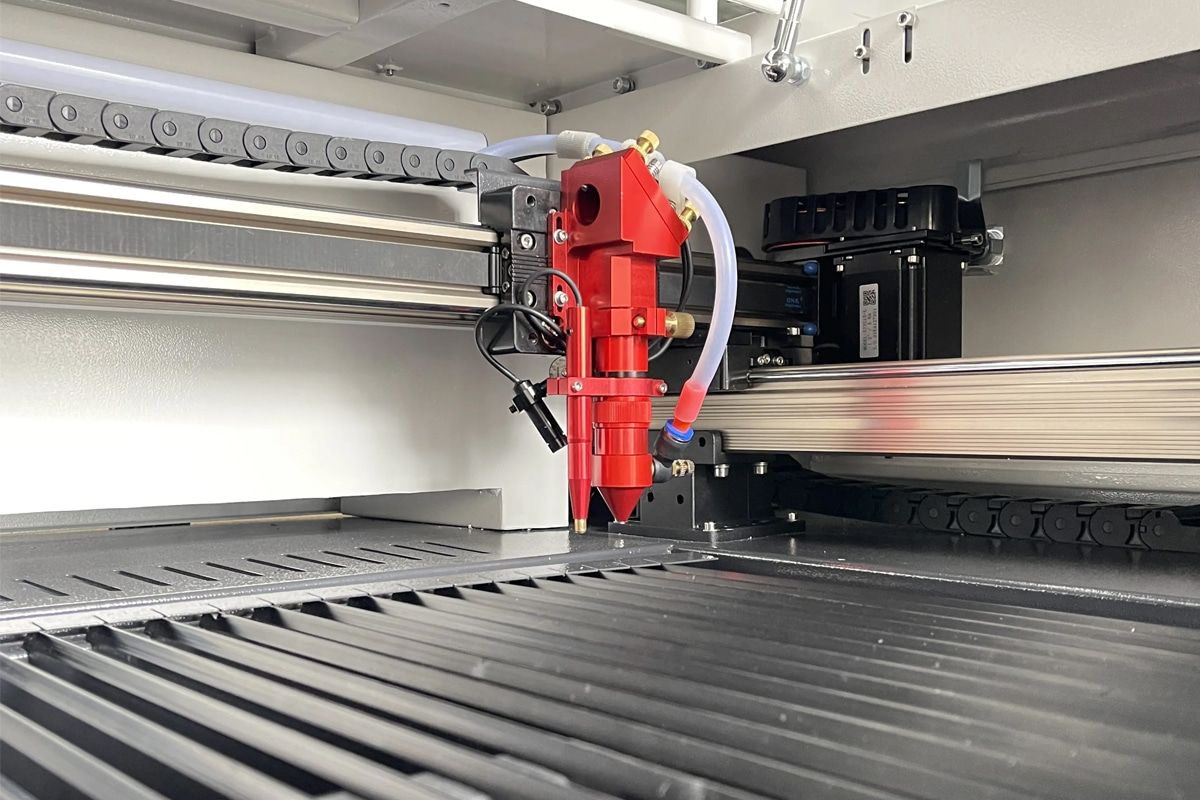

CO2 laser cutting machines represent one of the most widely used technologies for shaping, engraving, and processing materials with high precision. These systems use a gas mixture, traditionally carbon dioxide, nitrogen, hydrogen, and helium, to generate a concentrated laser beam capable of cutting a variety of surfaces including wood, acrylic, textile, leather, and certain metals. Their evolution aligns with industrial automation, digital fabrication, and the increasing demand for accuracy in manufacturing and design.

The fundamental purpose of CO2 laser cutting machines is to simplify material processing with greater precision compared to manual cutting techniques. Instead of physical contact between tools and surfaces, the laser executes cuts through controlled thermal energy. This method reduces tool wear, supports complex geometries, and enables consistent production quality even at high volumes. As industries adopt robotics, smart manufacturing, and automated workflows, CO2 laser systems continue to hold a significant place in production floors, workshops, research labs, and large-scale fabrication environments.

The growing relevance of CO2 laser cutting machines

CO2 laser cutting technology matters today because modern production environments demand accuracy, consistency, and reproducibility. Manual techniques often struggle to match the micro-level detailing achievable with a laser. These machines are widely adopted in sectors like industrial fabrication, automotive components, signage manufacturing, packaging, textiles, furniture, prototyping, and architectural modelling. Even small-scale creators working on crafting, modeling, and precision cutting benefit from CO2 laser tools.

Their relevance also aligns with digital design workflows. Vector files, CAD models, and automated nesting software allow users to optimize layouts, minimize waste, and maintain uniformity. As more industries focus on sustainability and resource efficiency, laser cutting machines support reduced scrap generation. They also enhance productivity because once design files are set, repeated output appears identical, enabling scalable production without manual recalibration.

CO2 lasers additionally support both cutting and engraving, making them suitable for dual-purpose applications. Their capacity to handle organic materials such as wood, MDF sheets, fabrics, cardboard, and paper makes them valuable in packaging development and prototyping. They also play a role in signage and branding where clean edges and finer detailing enhance presentation quality.

Developments and updates in recent years

The past year has seen gradual improvements in CO2 laser cutting machines, especially in control systems, beam delivery, safety, and integration with digital platforms. Recent developments include:

-

More stable RF-excited CO2 laser tubes for extended operating life (observed across manufacturers during 2024–2025).

-

Enhanced motion control systems with better acceleration response for fine detailing in design-heavy projects.

-

Improved cooling systems to maintain laser stability during long operational cycles.

-

Increased adoption of AI-based path optimization and automated calibration for precision alignment.

-

Browser-based machine controllers, enabling operation without full desktop software installation.

-

Growing emphasis on material-specific preset libraries for easier workflow execution.

Another shift has been toward hybrid and multi-mode machines that combine CO2 and fiber laser systems. These configurations are increasingly used where mixed-material processing is required, such as metals and non-metals in the same environment. Although fiber lasers dominate metal applications, CO2 systems remain preferred for non-metallic cutting due to surface finish quality and smoother edges.

The past year has also seen more recognition for machine safety and training due to rising usage among new-generation makers and educational institutions. Awareness programs now emphasize enclosure protection, fume extraction, power management, and fire-risk prevention.

Policies, regulations, and operational guidelines

CO2 laser cutting falls under generalized industrial machine safety regulations across most countries. While requirements vary, common guidelines involve:

-

Use of proper laser enclosures to prevent beam exposure.

-

Mandatory ventilation or fume extraction systems to handle smoke, dust, and vapor emissions.

-

Eye protection standards for operators near active laser output.

-

Electrical compliance certifications for laser equipment and associated controllers.

-

Material-specific handling rules, especially for plastics that release fumes during thermal cutting.

-

Workplace audit standards under occupational safety authorities.

Certain regional frameworks also reference laser classification categories, typically Class 3B and Class 4 for industrial CO2 laser machines. These classifications involve safety protocols for shielding, interlocks, emergency stops, and access-restricted operation zones. Institutions and workshops using laser systems often maintain logbooks, hazard training documentation, and fire safety equipment as part of compliance.

Users working with combustible materials like acrylic or cardboard are encouraged to monitor machine operation actively rather than leaving it unattended. The combination of heat and flammable material requires preventive awareness, especially in high-power systems.

Tools, resources, and digital support systems

Alongside physical machines, several tools and platforms help streamline workflows:

Design and file-preparation software

-

CAD and technical drawing programs

-

Vector-based design software for laser paths

-

Layout optimization tools for sheet placement

-

Browser-based controllers supporting remote access to machines

Material settings databases

-

Power and speed reference charts

-

Engraving depth and pass-count guidelines

-

Material-thickness tolerance tables

Safety and operational resources

-

Training modules for machinery handling

-

Laser classification reference documents

-

Technical maintenance checklists

Example reference table: power level vs material suitability

| Laser Power Range (W) | Best Used For | Typical Material Thickness |

|---|---|---|

| 40–80 W | Light engraving and soft material cutting | Thin sheets, paper, leather |

| 80–150 W | Industrial fabrication and prototyping | Medium-density materials |

| 150–300+ W | Heavy-duty production and thicker stock | Thick wood, acrylic, MDF |

These references help operators maintain consistency across different projects and ensure that cutting parameters align with material requirements.

Common questions and clear answers

What materials are suitable for CO2 laser cutting?

CO2 laser cutting machines work well with wood, paper, cardboard, leather, acrylic, textiles, and certain polished materials. While metal cutting is possible at higher power outputs, fiber lasers are generally preferred for metallic applications.

How does a CO2 laser generate cutting power?

Laser energy forms through electrical excitation of CO2 gas molecules within a resonant tube. The amplified beam is directed through mirrors and focusing lenses to a precise point, building heat that vaporizes material along the cutting path.

Are CO2 lasers safe to operate in a workshop environment?

They are safe when used within proper safety guidelines. This includes enclosure shielding, fume extraction, emergency shutdown controls, and eye-protection standards. Unattended operation is discouraged.

Do cutting results vary between materials?

Yes, different materials respond uniquely to thermal cutting. Wood produces darker burn edges while acrylic forms smooth, flame-polished lines. Thin fabrics cut quickly but require lower power to avoid distortion.

Why are CO2 lasers popular for non-metal applications?

The wavelength of CO2 lasers interacts efficiently with organic material, resulting in clean edges and refined engraving textures. This makes them suitable for packaging design, signage, artistic detailing, and natural material processing.

Summary Perspective

CO2 laser cutting machines continue to contribute to design engineering, manufacturing precision, digitized production, and rapid prototyping. Their core advantage lies in being able to translate digital concepts into real-world outputs with high accuracy. As workflows shift toward automated fabrication, CO2 lasers remain an important foundation for handling organic and composite materials with repeatable quality.

Future progression may introduce smarter calibration, lower energy consumption, cloud-linked controllers, and deeper integration with AI-based design-to-fabrication pipelines. Whether used in industrial environments, education labs, or custom fabrication studios, the technology supports detailed shaping and surface finishing without physical blade contact.