A Complete Guide to Homogenizer Machines: Insights, Facts, and Helpful Information

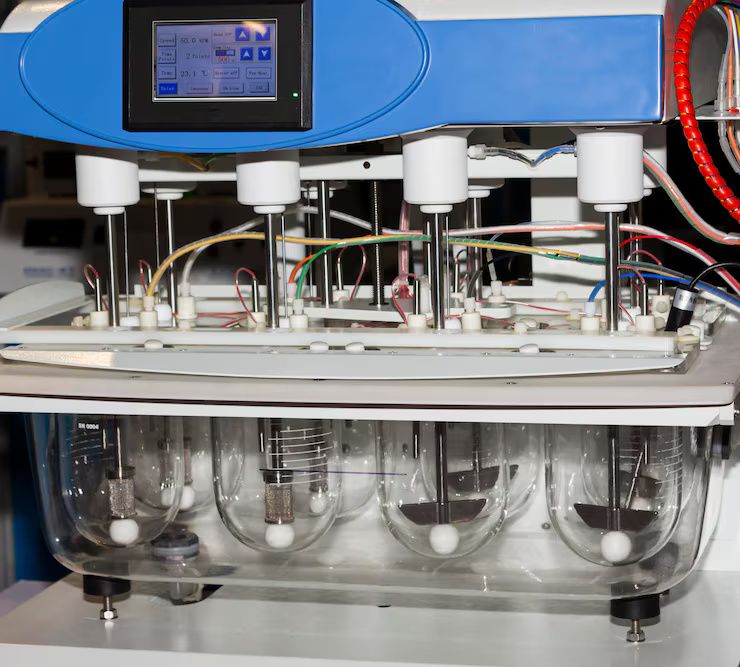

Homogenizer machines are widely used in industries that require consistent blending of liquids, solids, or semi-solids. Their purpose is to break down particles and distribute them evenly throughout a mixture. This process creates uniform textures, stable emulsions, and improved product quality.

Homogenization exists because many products—such as dairy beverages, cosmetics, pharmaceuticals, and chemical formulations—need consistency to function correctly or meet safety and quality standards. Without homogenization, mixtures may separate, become unstable, or produce unreliable results.

From simple mechanical models to advanced high-pressure systems, homogenizers have become essential in modern manufacturing and scientific processes. They operate through principles like pressure, mechanical force, ultrasonic waves, or rotor-stator technology to achieve desired particle sizes.

Importance

Homogenizer machines play an essential role in today’s manufacturing, scientific, and food-processing environments. Their importance can be understood through several perspectives:

-

Product consistency: Ensures uniform texture, flavor, and appearance in foods, beverages, and cosmetics.

-

Safety and stability: Reduces particle size to create more stable formulations, preventing separation and contamination risks.

-

Efficiency: Enables faster production, predictable results, and reduced material waste.

-

Innovation support: Helps researchers create new formulations in fields like biotechnology, pharmaceuticals, and nanotechnology.

-

Global quality standards: Many industries must meet strict quality controls, and homogenization supports compliance.

Industries most affected include dairy processing, personal care, chemical manufacturing, biomedical research, and nutraceutical production. These machines solve the challenge of achieving uniformity in mixtures where ingredients naturally resist blending.

Recent Updates

Several advancements between 2024 and 2025 have shaped how homogenizer machines are designed and used:

-

Energy-efficient models (2024): New systems are engineered to reduce energy consumption while maintaining high performance, supporting sustainability goals.

-

High-pressure innovation (2025): Machines capable of pressures above 3000 bar are now used in biotech and pharmaceutical research to achieve ultra-fine emulsions and nanoscale particle sizes.

-

Smart monitoring technology (2025): Sensors and IoT platforms allow real-time monitoring of temperature, pressure, and downstream quality indicators.

-

Automated cleaning cycles (2024): Advanced designs include self-cleaning programs that reduce downtime and improve sanitation in food and pharmaceutical applications.

-

Noise-reduction improvements (2024): Ultrasonic homogenizers now include enhanced sound-dampening chambers for safer laboratory environments.

A 2025 manufacturing technology report highlights growing demand for homogenizers across global food processing and life sciences sectors due to evolving quality expectations and innovation trends.

Laws or Policies

Homogenizer machine use is closely connected to regulations that ensure product safety, environmental responsibility, and quality compliance. These policies vary by region but share similar principles:

-

Food safety regulations: Agencies such as the FDA (United States) and EFSA (European Union) enforce standards for dairy and food manufacturers, many of which require validated homogenization processes.

-

Good Manufacturing Practices (GMP): Pharmaceutical and cosmetic industries follow GMP guidelines, which include standards for equipment cleanliness, calibration, and process control.

-

Occupational safety laws: Organizations like OSHA and HSE regulate safe operation of mechanical and high-pressure equipment to protect workers.

-

Environmental policies: Some regions encourage energy-efficient machinery to reduce industrial emissions and support sustainability.

-

International equipment standards: ISO certifications govern aspects like pressure resistance, material safety, cleaning protocols, and mechanical integrity.

These laws help ensure homogenizers are used in a safe, controlled, and environmentally responsible manner, especially in sensitive industries like food and medicine.

Tools and Resources

Several digital and industry resources support users, researchers, and technicians in working with homogenizer machines:

-

Particle size analysis tools: Software platforms and calculators help determine optimal particle reduction metrics.

-

Process modeling applications: Platforms like COMSOL Multiphysics offer simulations for understanding fluid behavior during homogenization.

-

Laboratory management apps: LIMS systems track sample processing, homogenization parameters, and test results.

-

Safety and compliance websites: Organizations publish safety sheets, equipment standards, and best practices for equipment handling.

-

Scientific databases: Access to journals helps researchers explore new homogenization methods, nanotechnology applications, and case studies.

-

Manufacturer manuals: Technical guides support proper operation, maintenance schedules, and calibration instructions.

Example Table: Common Types of Homogenizer Machines and Their Applications

| Homogenizer Type | Principle Used | Typical Application Area |

|---|---|---|

| High-Pressure | Compression and turbulence | Dairy, pharmaceuticals |

| Ultrasonic | Sound waves and cavitation | Nanomaterials, lab research |

| Rotor-Stator | Mechanical shear | Cosmetics, sauces, creams |

| Bead Mill | Grinding with beads | Cell disruption, biotechnology |

| Inline Homogenizer | Continuous fluid mixing | Large-scale manufacturing |

FAQs

What is a homogenizer machine used for?

A homogenizer machine is used to break down particles and blend ingredients to create smooth, uniform, and stable mixtures. It is commonly used in food processing, cosmetics, pharmaceuticals, and scientific research.

How does a high-pressure homogenizer work?

High-pressure homogenizers force material through a narrow valve at extreme pressure, creating turbulence and shear that reduce particle size and create a uniform mixture.

Are homogenizers used in biotechnology?

Yes, many biotechnology laboratories use homogenizers for cell disruption, protein extraction, and preparation of nano-emulsions.

What safety precautions should be taken when using homogenizers?

Operators should follow equipment guidelines, avoid contact with moving parts, use pressure-rated protective equipment, and ensure proper cleaning to prevent contamination.

Do homogenizers support eco-friendly manufacturing?

Modern homogenizers often include energy-efficient designs, automated cleaning cycles, and reduced waste features that help support environmentally responsible production.

Conclusion

Homogenizer machines play an essential role in producing consistent, safe, and high-quality products across industries. Their ability to reduce particle size, improve texture, and enhance stability supports everything from everyday consumer goods to advanced scientific research.

With recent improvements in smart technology, high-pressure capabilities, and automation, homogenizers continue to evolve to meet modern manufacturing needs. Regulations help ensure their safe and responsible use, while digital tools provide users with valuable support for analysis and process design.