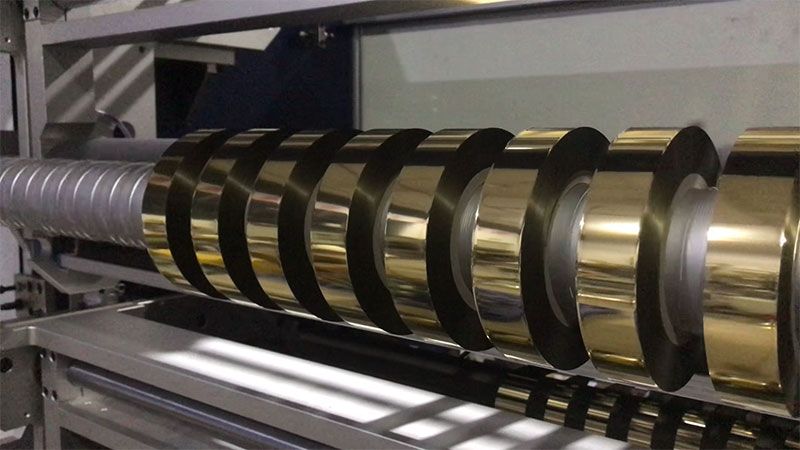

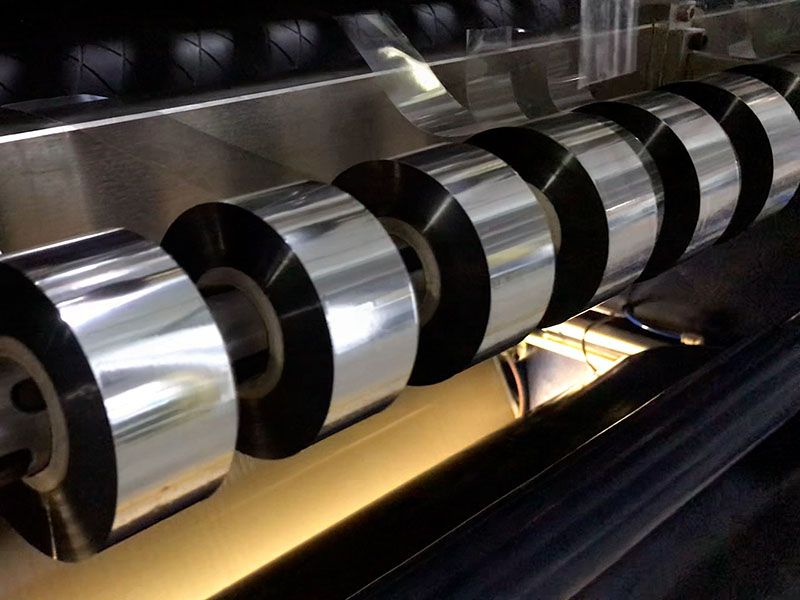

Instead of relying on manual cutting, which is time-consuming and prone to errors, these machines use automated systems that ensure accuracy, reduce waste, and improve productivity. Depending on the application, slitting machines may use razor blades, rotary knives, or shear systems to achieve the desired cut.

They are widely used in sectors ranging from printing and packaging to automotive, construction, and electronics manufacturing.

Importance

The role of automatic slitting machines in modern industries cannot be overstated. Their importance lies in several key areas:

-

Efficiency in production – By automating the cutting process, industries save time and achieve consistent quality.

-

Precision and uniformity – Slitting machines ensure exact widths for each strip, which is essential for industries like electronics and medical devices.

-

Material optimization – They help reduce waste by cutting with minimal errors, lowering environmental impact.

-

Scalability – Automatic machines support high-volume production, making them suitable for industries operating on large scales.

-

Worker safety – Automated controls reduce the risks associated with manual cutting methods.

Industries most affected include packaging, where films and foils are constantly slit into usable sizes; metalworking, where sheets are prepared for fabrication; and textiles, where fabrics are cut into precise strips for clothing and upholstery.

Recent Updates

In the past year, significant advancements have been introduced to improve the efficiency, sustainability, and adaptability of automatic slitting machines. Some notable updates from 2024–2025 include:

-

Integration of smart controls (2024): Machines are now equipped with touchscreen interfaces and automated tension control systems to enhance ease of use and accuracy.

-

AI-assisted monitoring (2025): Artificial intelligence is being used to predict blade wear and schedule maintenance before breakdowns occur.

-

Eco-friendly focus (2024): Manufacturers are designing machines to reduce energy consumption and optimize cutting paths, aligning with environmental goals.

-

High-speed digital slitting (2025): Systems are now capable of handling thinner materials at higher speeds without compromising accuracy.

-

Industry 4.0 compatibility (2024–2025): Many machines are now connected to factory networks, allowing real-time data tracking and performance analysis.

These updates reflect the growing demand for sustainability, automation, and precision in industrial manufacturing.

Laws or Policies

Regulations influence the design, operation, and safety standards of automatic slitting machines worldwide. Some key policies include:

-

ISO Standards: International standards define requirements for machine safety, quality, and testing, ensuring global consistency.

-

Occupational Safety and Health Administration (OSHA) regulations (United States): These guidelines protect workers from risks associated with machinery operation.

-

European Machinery Directive: Enforces safety design and risk assessment requirements for industrial machinery used in the EU.

-

Environmental regulations: Many countries are adopting stricter sustainability policies that encourage energy-efficient and waste-reducing manufacturing equipment.

-

National workplace safety laws: In regions such as Asia-Pacific, governments are implementing stricter operator training requirements for machinery use.

Compliance with these regulations not only ensures worker safety but also enables industries to meet environmental and operational standards.

Tools and Resources

To support industries and engineers working with slitting machines, several tools and resources are available:

-

Slitting calculators: Online tools help determine blade spacing, material tension, and roll dimensions.

-

CAD software: Used for designing and simulating slitting operations before production begins.

-

IoT monitoring dashboards: Provide real-time machine performance insights for predictive maintenance.

-

Material databases: Engineering databases offer detailed cutting parameters for different materials like metals, plastics, or textiles.

-

Educational courses: Online training programs and webinars provide instruction on machine operation, safety, and maintenance best practices.

FAQs

What materials can be processed with automatic slitting machines?

They are versatile and can process paper, plastics, textiles, aluminum, steel, copper, and composite films. The choice of blade and machine design depends on the material’s thickness and properties.

How do automatic slitting machines improve efficiency compared to manual cutting?

They provide faster throughput, reduce operator fatigue, and ensure consistent widths with minimal waste. This increases productivity and accuracy across production lines.

Are slitting machines safe to operate?

Yes, when operated according to safety regulations. Modern machines include safety guards, emergency stop systems, and automated blade handling features to reduce risks.

What industries use slitting machines the most?

Packaging, printing, paper production, metal fabrication, textiles, and electronics manufacturing are among the leading industries that rely on slitting machines.

How often should slitting blades be maintained or replaced?

The frequency depends on the material being cut and the volume of production. With predictive monitoring systems, blade wear can be detected early, reducing downtime.

Conclusion

Automatic slitting machines play a vital role in modern manufacturing, bridging efficiency, precision, and sustainability. Their significance extends across industries that rely on accurate material preparation, from packaging and textiles to metals and electronics.

With recent advancements like AI-driven monitoring, energy-efficient systems, and Industry 4.0 integration, these machines are evolving into smarter and more sustainable solutions. Regulations and standards ensure that their use remains safe and environmentally responsible, while tools and training resources support engineers and operators.