Guide to Industrial HVAC Optimization: Discover Key Facts and Resources

Industrial HVAC optimization refers to the process of improving heating, ventilation, and air conditioning systems used in large-scale facilities such as factories, warehouses, and production plants. These systems are essential for regulating indoor air quality, maintaining temperature stability, and ensuring safe working conditions.

The topic exists because HVAC systems are among the largest consumers of energy in industrial settings. In many facilities, HVAC may account for up to 40% of total energy use. Without optimization, systems often operate inefficiently, leading to unnecessary energy consumption, higher environmental impact, and reduced equipment lifespan.

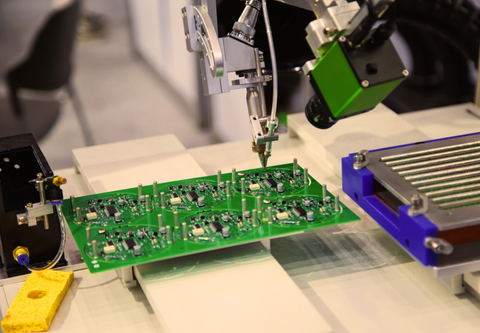

Optimization involves strategies such as upgrading controls, monitoring airflow, using smart sensors, and scheduling preventive maintenance. It also includes adopting modern technologies like variable frequency drives (VFDs), advanced filtration, and automated monitoring systems.

Importance

Optimizing industrial HVAC systems matters for multiple reasons:

Energy efficiency: Reduces energy demand and minimizes greenhouse gas emissions.

Workplace safety: Ensures proper ventilation to reduce airborne contaminants.

Regulatory compliance: Helps industries meet environmental and occupational health standards.

Operational continuity: Prevents downtime caused by HVAC malfunctions in sensitive environments such as food production or chemical manufacturing.

The topic affects a wide audience including plant managers, engineers, policymakers, and sustainability professionals. For example, in a pharmaceutical plant, temperature and humidity control are critical for product safety. In data centers, cooling optimization prevents equipment overheating.

Problems solved through optimization include:

Excessive operational expenses due to wasted energy

Poor indoor air quality leading to health risks

Non-compliance with evolving energy standards

Equipment breakdowns due to irregular maintenance

Recent Updates

Several trends and updates in 2024–2025 are shaping industrial HVAC optimization:

AI-driven controls (2024): Artificial intelligence is increasingly used to automate HVAC scheduling and performance monitoring. AI tools can predict demand patterns and adjust airflow in real time.

Electrification initiatives (2025): Many governments encourage replacing gas-powered heating systems with electric alternatives to support decarbonization goals.

Green building standards: Updated certifications such as LEED v5 (2024 release) emphasize stricter HVAC energy requirements for industrial spaces.

Heat recovery systems: Adoption of heat exchangers in manufacturing plants grew significantly in 2024, with industry reports highlighting savings of up to 30% in heating demand.

IoT integration: By late 2024, over 50% of new industrial HVAC systems were being installed with IoT-enabled sensors for predictive maintenance.

Laws or Policies

Industrial HVAC optimization is influenced by national and international regulations. Common frameworks include:

ASHRAE Standards: Widely used globally, they provide benchmarks for energy efficiency, ventilation, and indoor air quality.

U.S. Department of Energy (DOE) Programs: Initiatives such as the Better Plants Program encourage industries to adopt optimized energy management practices.

European Union Energy Efficiency Directive (EED): Requires large industries to conduct regular energy audits, which often highlight HVAC inefficiencies.

Occupational Safety and Health Administration (OSHA): In the U.S., OSHA ventilation requirements affect industrial workplaces with airborne contaminants.

National Emission Standards: Countries such as Germany and Japan have adopted stricter emission rules, making optimized HVAC performance a compliance necessity.

These policies reflect a global shift toward sustainability and workplace safety, compelling industries to invest in efficient HVAC solutions.

Tools and Resources

Several resources are available for those interested in industrial HVAC optimization

Energy modeling software: Tools like EnergyPlus and TRACE 3D Plus help simulate HVAC performance in industrial facilities.

IoT platforms: Schneider EcoStruxure and Siemens Desigo provide industrial HVAC monitoring and optimization systems.

Calculators: The U.S. Department of Energy provides online calculators for estimating potential energy savings from system upgrades.

Guidelines and standards:

ASHRAE Handbook—HVAC Applications

ISO 50001 (Energy Management Systems)

LEED and BREEAM certification guides

Industry reports: Annual publications from the International Energy Agency (IEA) on energy efficiency trends in industrial facilities.

FAQs

What does HVAC optimization mean in industrial facilities?

It refers to improving heating, ventilation, and cooling systems to maximize energy efficiency, reduce environmental impact, and maintain safe air quality and working conditions.

How much energy can be saved by optimizing HVAC systems?

Savings vary depending on system age and facility type, but studies show that optimization measures can reduce energy use by 20–40%.

What role does predictive maintenance play in HVAC optimization?

Predictive maintenance uses data from sensors to identify issues before they lead to breakdowns, reducing downtime and extending system lifespan.

Are there global standards for industrial HVAC optimization?

Yes. Standards such as ASHRAE, ISO 50001, and LEED provide guidelines for energy-efficient and safe HVAC design and operation.

What are the most common optimization techniques?

These include installing variable frequency drives, using advanced filtration systems, upgrading building automation systems, and applying AI-driven controls for real-time adjustments.

Conclusion

Industrial HVAC optimization is a crucial part of modern facility management, linking energy efficiency, worker safety, and environmental responsibility. With new trends like AI integration, IoT sensors, and electrification initiatives, industries have more opportunities than ever to reduce energy consumption and comply with evolving standards.

By using available tools, following established regulations, and applying modern optimization techniques, industries can improve performance while contributing to broader sustainability goals. HVAC optimization is no longer just a technical concern—it has become a vital aspect of industrial resilience and responsible operations in 2025 and beyond.