Custom Cable Solutions Explained: A Complete Guide to Assemblies, Connectors & Quotes

Custom cable solutions are engineered combinations of conductors, insulation, shielding, and connectors designed to support specific electrical, mechanical, or environmental requirements. They exist because many modern systems industrial automation, renewable energy, medical equipment, aerospace electronics, robotics, and data infrastructure need wiring that standard off-the-shelf cables cannot provide.

As technology becomes more advanced and compact, cables must handle higher data rates, increased power, extreme temperatures, noise protection, and unique routing needs. This has pushed industries to focus on tailored assemblies and connector configurations that ensure reliable performance.

Importance

Custom cable solutions matter today because systems have become more specialized and interconnected. Industries depend on precise electrical and signal communication, and even small failures can interrupt productivity, safety, or data integrity.

These solutions matter for:

-

Manufacturers improving equipment reliability and integrating sensors or miniaturized components.

-

Automation and robotics teams requiring flexible and durable assemblies.

-

Healthcare technology developers working with diagnostic devices, imaging systems, and monitoring tools.

-

Energy and infrastructure projects aiming for secure transmission of power and data.

-

Telecommunications and networking environments where bandwidth and signal quality are critical.

They solve several problems:

-

Reduce electrical interference through shielding variations.

-

Improve performance through custom conductor sizing and insulation.

-

Enhance safety by meeting operational and environmental demands.

-

Simplify installation through tailored lengths, labeling, and connector compatibility.

-

Support evolving high-bandwidth and high-precision technologies.

Recent Updates

The past year has seen notable changes in cable engineering, material science, and manufacturing approaches.

2024–2025 developments include:

-

Higher-speed data assemblies designed for AI servers, edge computing, and advanced networking (updated throughout 2024).

-

Growing focus on electromagnetic compatibility due to increasing device density in industrial and medical spaces (Q2 2024).

-

Adoption of halogen-free insulation in line with global safety and sustainability trends (2024).

-

Increased demand for hybrid cables that combine power and data within a single assembly for robotics and smart manufacturing (late 2024).

-

Improved miniature connectors supporting wearables, healthcare sensors, and compact devices (2025).

-

Shift toward traceable manufacturing using QR codes or laser markings for quality assurance (2024–2025).

Across sectors, engineers are prioritizing advanced shielding techniques, enhanced flexibility, and materials that support higher temperatures and vibration resistance.

Laws or Policies

Custom cable solutions are shaped by safety standards, environmental regulations, and electrical guidelines that vary across regions. While requirements differ by country, several widely recognized policies influence how cables and connectors are designed and used.

Common regulatory frameworks include:

-

RoHS (Restriction of Hazardous Substances): Limits hazardous materials in electrical components.

-

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Governs chemical safety in materials used for insulation and jackets.

-

IEC (International Electrotechnical Commission) standards: Provide global benchmarks for electrical functionality, insulation, fire-resistance, and testing.

-

ISO quality standards: Influence documentation, traceability, and manufacturing practices.

-

UL and CSA certifications: Commonly used for verifying cable safety, flammability ratings, and electrical performance.

Different sectors have specific requirements:

-

Medical equipment: Must follow IEC 60601 standards for electrical safety.

-

Aerospace and defense: Often require MIL-SPEC standards and strict performance validation.

-

Automotive applications: Must adhere to ISO 19642 guidelines for road-vehicle cables.

These frameworks ensure that cable assemblies deliver predictable performance, environmental compliance, and operational safety.

Tools and Resources

A variety of digital tools and resources support the planning, selection, and evaluation of cables, assemblies, and connectors.

Design and configuration tools

-

Cable layout planners

-

Connector compatibility checkers

-

Shielding and insulation visualizers

Engineering calculators

-

Voltage drop calculators

-

Wire gauge calculators

-

Current capacity calculators

-

Temperature-rating estimators

Technical resources

-

Material comparison charts

-

Bend-radius guidelines

-

EMI/EMC reference guides

-

UL/IEC standards databases

Selection aids

-

Connector pin-mapping templates

-

Cable routing templates

-

Assembly documentation tools

These resources help engineers and teams evaluate conductor sizes, choose insulation materials, verify environmental ratings, and ensure signal integrity for their system requirements.

Key Concepts and Components

Cable assemblies

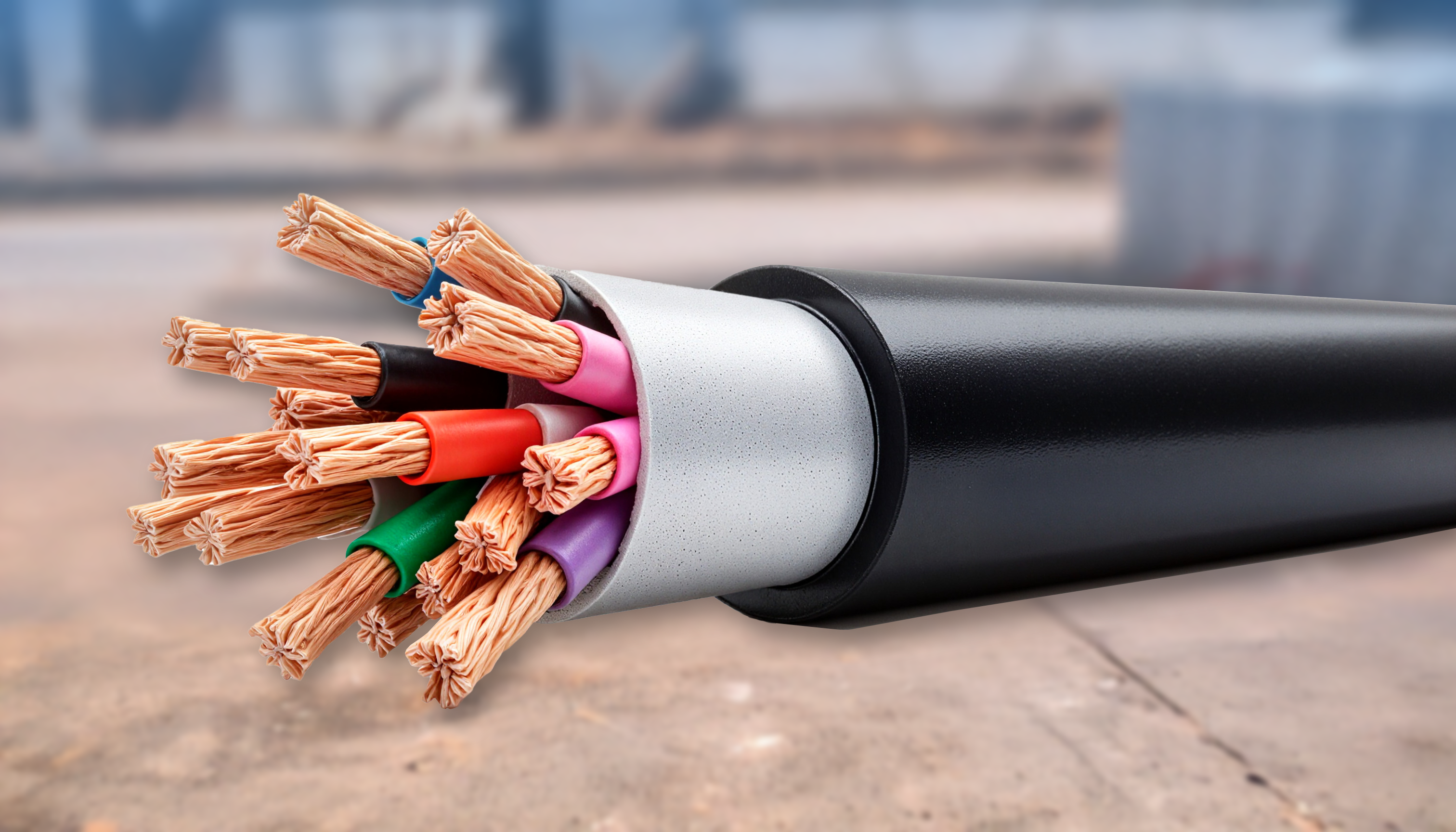

Cable assemblies combine multiple wires or fibers into a structured, protected format. They often include:

-

Bundled conductors

-

Insulation layers

-

Braided or foil shielding

-

Outer jackets

-

Pre-terminated connectors

They are used to streamline installation, reduce wiring errors, and improve mechanical durability.

Connector types

Connectors determine how cables interface with equipment. Common types include:

-

Circular connectors

-

Rectangular connectors

-

RF/Coaxial connectors

-

Ethernet connectors

-

Fiber-optic connectors

-

PCB board-to-cable connectors

Choosing the correct connector involves evaluating pin count, locking mechanisms, environmental sealing, and electrical performance.

Example Comparison Table: Connector Types

| Connector Type | Typical Use Cases | Advantages | Key Considerations |

|---|---|---|---|

| Circular | Industrial, aerospace, sensors | Rugged, sealed options | Requires precise pin mapping |

| Ethernet | Networking, automation | High-speed data | Follows specific category standards |

| RF/Coaxial | Communication, antennas | Low-loss signal | Sensitive to interference |

| Fiber-optic | High-bandwidth systems | Extremely fast, EMI-free | Mechanical precision required |

| PCB Connectors | Internal electronics | Compact | Limited environmental protection |

Example Table: Insulation Materials

| Material | Temperature Range | Features | Typical Applications |

|---|---|---|---|

| PVC | Moderate | Flexible, common | General electronics |

| Teflon (PTFE) | High | Heat resistant, chemical stable | Aerospace, medical |

| Polyethylene | Low-loss | Strong signal integrity | Data, RF assemblies |

| Silicone | Wide | Highly flexible | Robotics, moving parts |

FAQs

1. What is the difference between a custom cable and a standard cable?

A custom cable is engineered to meet specific electrical, mechanical, or environmental needs, while standard cables follow general-purpose specifications. Custom configurations allow tailored conductor counts, insulation types, connectors, shielding, and lengths.

2. How do engineers determine the correct connector for an assembly?

They evaluate pin requirements, signal type, environmental conditions, installation space, mechanical load, and compliance standards. Choosing the right connector ensures safe and accurate communication between devices.

3. What factors influence cable performance in harsh environments?

Key factors include insulation material, shielding method, jacket durability, temperature tolerance, vibration resistance, and sealing. Designing for conditions such as moisture, chemicals, or high EMI improves reliability.

4. Why is shielding important in modern assemblies?

Shielding protects the signal from electromagnetic interference. As more equipment runs simultaneously in industrial and medical environments, EMI control is essential for accuracy and consistency.

5. How do hybrid cables support modern technology?

Hybrid cables combine power, control, and data conductors into one assembly, reducing routing complexity and improving system efficiency. They are widely used in robotics, automation, and sensor networks.

Conclusion

Custom cable solutions play a critical role in supporting today’s advanced electrical and electronic systems. As industries grow more interconnected and data-driven, they rely on assemblies and connectors that deliver precision, durability, and compatibility. Recent developments in insulation materials, EMI protection, miniaturization, and hybrid designs show how rapidly the field is evolving.

By understanding the components, regulatory requirements, and available tools, engineers and project teams can make informed technical decisions that strengthen system reliability and performance. This guide provides a clear foundation for navigating assemblies, connectors, materials, and best practices as custom cable needs continue to grow across sectors.